Processes

Fusing waterjet, laser for efficiency in CFRP/CMC machining

Laser MicroJet technology offers high accuracy and speed without heat issues, burring or replacement of cutting tools.

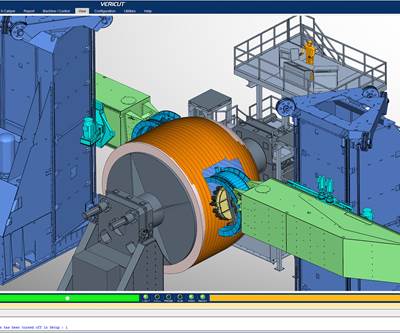

Read MoreSmarter, integrated data for ATL/AFP

More than helping to eliminate dry runs and costly errors, AFP/ATL software is beginning to benefit the whole product lifecycle through the interconnectedness of the digital thread.

Read MoreSpirit AeroSystems acquires robotic Electroimpact AFP machine

The new machine, featuring an upgraded AFP head said to place material more than twice as fast as traditional machines, will be devoted to research and development.

Read MoreBallistic panels protect school

A composites manufacturer has developed military-grade pultruded panels that are being used to protect schools in case of violent intruders.

Read MoreKraussMaffei expands LFI and SCS processing with shuttle mold carrier

At the Munich-based TechCenter, the MX mold carrier is developed to improve fiber injection and spraying capabilities including for large, Class-A components.

Read MoreHexcel fabrics chosen for Sunseeker performance cruiser

Hexcel’s HiMax Dot Pattern Adhesive fabrics have been chosen for resin infusion of Sunseeker’s newest high-performance luxury yacht.

Read MoreZero-waste: New process, equipment recycles prepreg, tape offal

Technology provides sustainable approach to reusing valuable thermoplastic scrap in chips-based laminate.

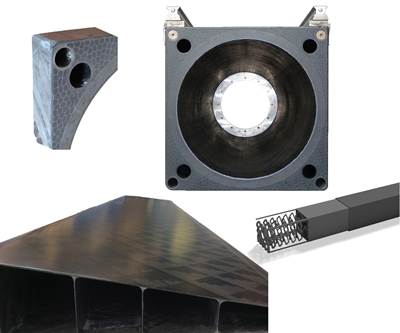

WatchInnovating composites to open new markets

From machine tools to trainer jets, CompoTech develops new design and process solutions.

Read MoreMississippi State opens Marvin B. Dow Stitched Composites Development Center

The new research center, built in partnership with Boeing, will work with stitched, resin-infused composites to advance composite materials for aerospace.

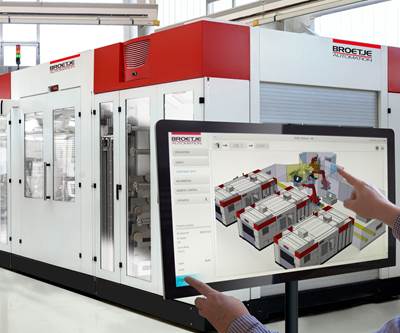

Read MoreBroetje-Automation enlarges AFP portfolio for serial composite production

The STAXX product line of automated fiber placement (AFP) machining centers is designed for both thermoplastic and thermoset composite applications.

Read More