“Too often, designs are thrown over the wall to manufacturing.” Neatly summarizing a common yet undesirable state of affairs, Robert Yancey, director of manufacturing and production industry strategy and business development at Autodesk (San Rafael, Calif., U.S.), goes on to talk about the “convergence of design and manufacturing” to which his company is devoting significant resources. Such efforts are a crucial element in the build-out of the digital thread, which is meant to provide the communications framework that ultimately will connect functions throughout a product’s lifecycle.

Variously called “smart manufacturing,” the “Industrial Internet of Things (IIoT),” or “Industry 4.0” (alternately, “Industrie 4.0”), the digitalization of today’s manufacturing operations is well underway in many sectors. In some instances, like the fully automated Siemens (Munich, Germany) Simatic programmable logic controller (PLC) factory in Amberg, Germany, or the Composites Technology Center (CTC, Stade, Germany; a subsidiary of Airbus Operations GmbH), full digitalization has been deliberately implemented from near-clean sheet design. Much more commonly, though, manufacturers must transition incrementally from existing operations to the fully digital future.

In the case of automated fiber placement (AFP) and automated tape laying (ATL) systems, digitalization of composites fabrication is lagging a few steps behind other manufacturing operations — and with good reason. “Composites manufacturing is radically different and not as mature as metal cutting,” notes Andre Colvin, composites products manager at CGTech (Irvine, Calif., U.S.), adding, “Machine builders and users all hold their cards close to the chest. They want to maintain every advantage possible over the competition.”

Yet discernable progress is occurring in AFP/ATL digitalization on two fronts. First, machine-independent software continues to mature, enabling a composites manufacturer to use the same software package on different AFP/ATL brands. This maturation also means developing support for new AFP/ATL or similar technologies within the software package. Second, software developers are working to implement the digital thread so that different functional groups within design and manufacturing communicate and interact more directly and efficiently.

AFP/ATL digital automation pieces

To optimize the efficiency of an AFP/ATL or similar system, fabricators strive to achieve the dual objectives of (1) running the machine at the maximum feed rate as often as possible, while (2) minimizing production errors by slowing down in areas of the layup where multiple material cuts and adds take place repeatedly or in areas of high contour. Described in the 2017 CGTech whitepaper “Roadmap to Automated Composites,” these objectives are prompting ongoing developments in the machines themselves, from the end effectors laying down the material to robotics and novel high-speed continuous-fiber preforming approaches. Of equal importance, though, is ongoing development of the software that enables the machine to produce the component as designed, or to alert designers of needed changes for manufacturability.

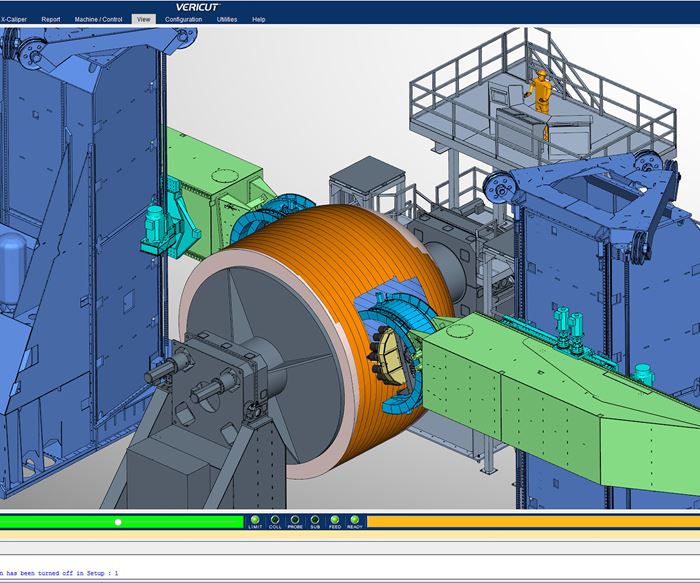

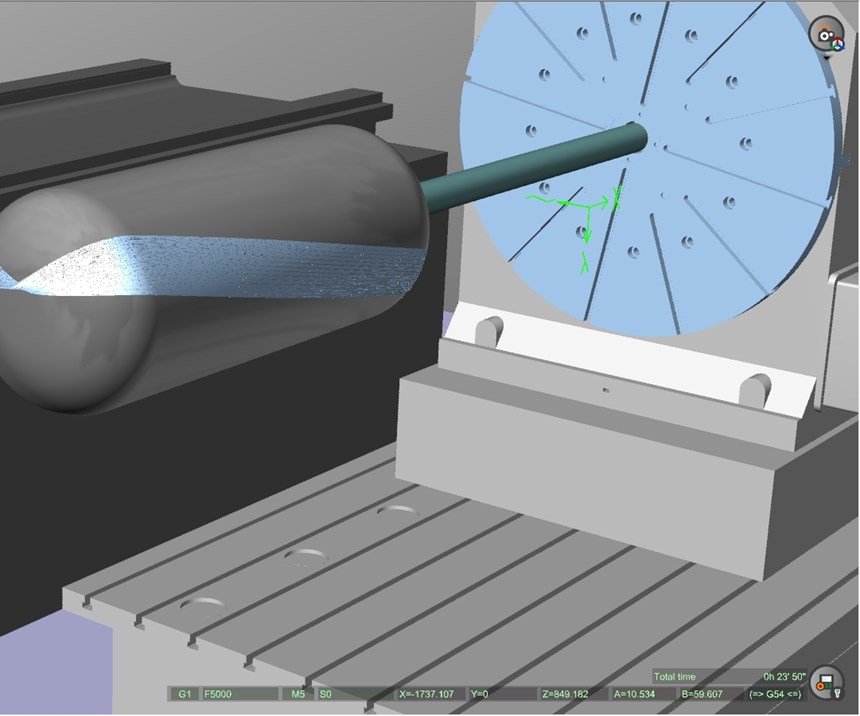

AFP/ATL manufacturing software consists of multiple modules. Machine control software — the numerical code (NC), most commonly “G-code” — directs the machine’s movements and operational settings. Machine programming software, or path-planning software, provides operational data to the controller, via postprocessing, for each component to be built. This software dictates the direction and position in which the material will be placed. It is designed to optimize tool paths, feed rates and other operational parameters. Simulation software, working in concert with machine programming, takes the engineering of a production run offline and enables manufacturers to visualize production on-screen. It does so by processing the G-code that the postprocessor has generated. Digital simulation replaces dry runs on the actual production equipment, saving significant time and cost. “These are high-value machines, and the material being laid down is expensive,” Yancey says. “So any activity on the machine that is not making the product is costly.”

A decade ago, CW reported on AFP/ATL control, programming and simulation software, and even by then, these products had followed a familiar path for industrial software solutions. First, the inventor of a new production technology employs an in-house software development team (or a closely allied software development partner) to create machine control programs tailored to the particular production system being developed. When other companies create similar competing technology, they too generate proprietary software designed specifically for each system. As programming and control software is established, machine manufacturers want to relieve their customers of the need to perform dry test runs on the machine itself, and so simulation software is created to enable offline testing and validation of the machine program.

Machine independence

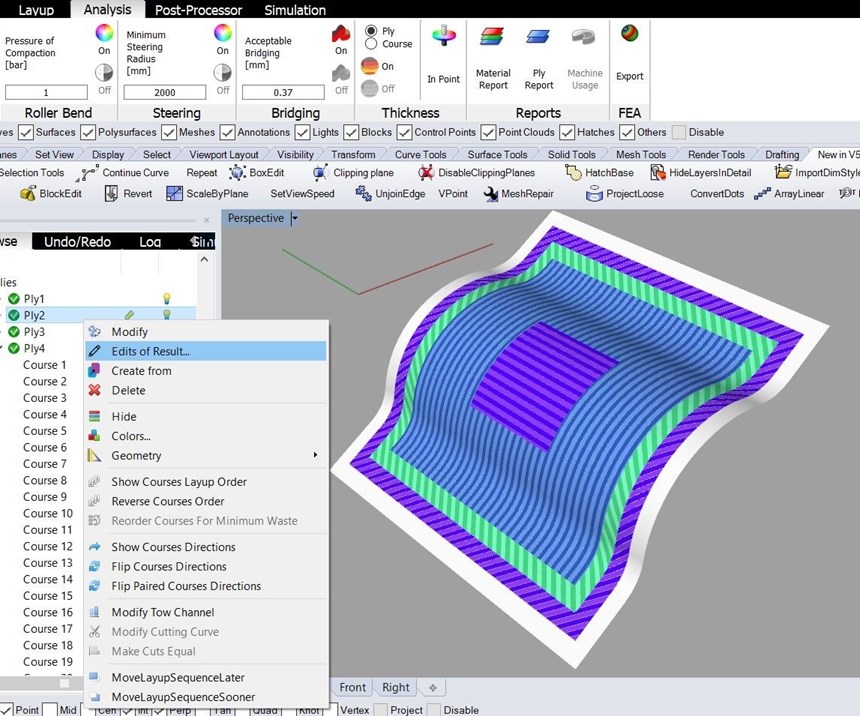

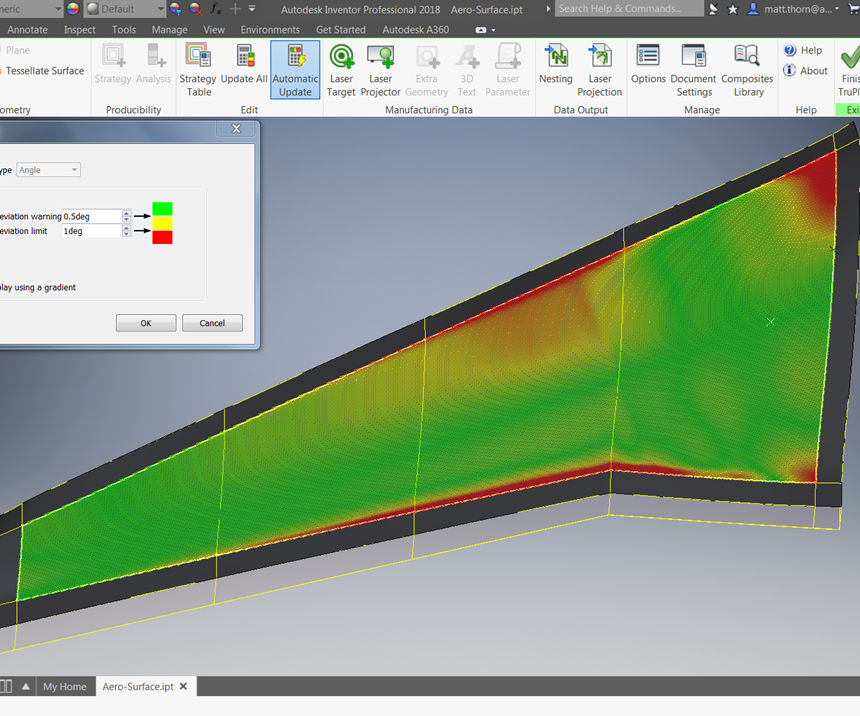

The basic goal of AFP/ATL software is to read composite part design data from the CAD system, then to create and simulate an NC program for the automated layup machine. Getting from CAD to a successful NC program is an iterative, multi-step process. Of course, even before the CAD file is first sent to manufacturing software, multiple steps typically occur within the design, including laminate and ply design, analysis and simulation. Next, a tool surface is designed using the CAD data, generating information that is as essential to the layup machine as the part information. Machine programming imports part and tool information and creates the NC paths. Some iteration occurs at this point: paths that meet the requirements of the material and of the AFP/ATL process are fed back to the CAD program to ensure that the design can be produced. This process accounts for factors such as material steering limits, the curvature of the tool, overlaps and gaps, and minimum tow length.

Once the machine programming and design modification have reached a satisfactory result, a postprocessor generates code specific to the AFP/ATL machine being used. “For each step in creating these part programs comes the possibility of introducing a mistake,” Colvin notes. “If there is a missing tow or material is placed somewhere other than where you were expecting, it is very expensive to have to scrap the component.” Therefore, the NC code is next used to simulate the layup process via the manufacturing simulation program. This is another iterative point where the process can be validated, problems can be detected and the machine programming can be adjusted and simulated again until there is high confidence in the final version of the NC program, which at last is sent to the machine.

As the number of companies offering similar production technology grows, OEMs and other large manufacturers do not want their engineering teams to have to learn and maintain multiple software packages from machine to machine, so demand for machine-independent software has grown. This is how CGTech first became involved in AFP/ATL software development. In 2004, as The Boeing Co. (Chicago, Ill., U.S.) was implementing AFP technology for major 787 Dreamliner components, it was clear that multiple AFP/ATL machine types would be employed by Boeing internal teams as well as its tier suppliers. For this reason, CGTech developed its software in a way that would enable it to work with any AFP/ATL system.

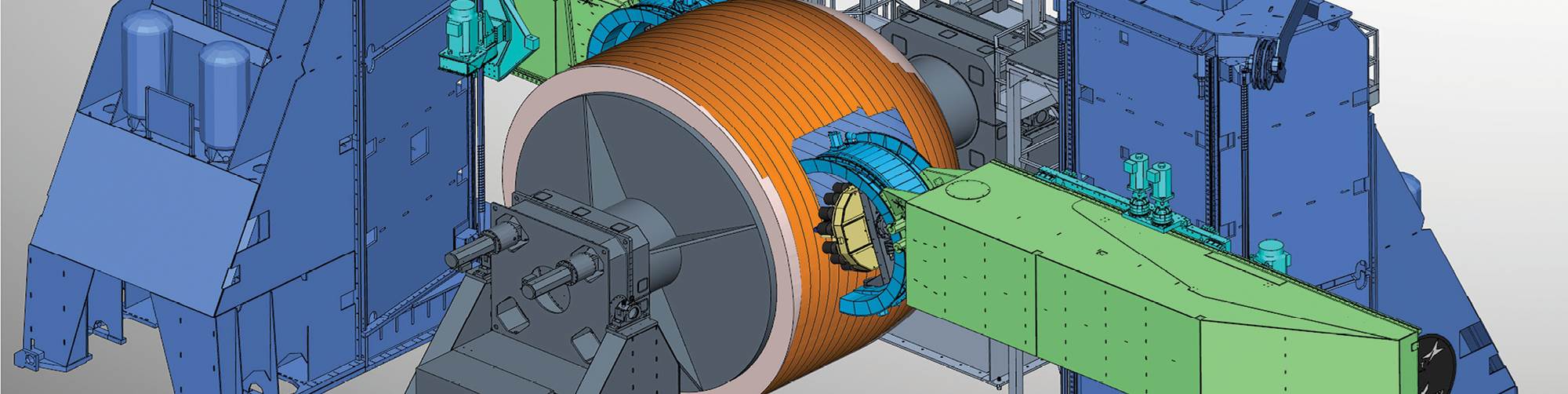

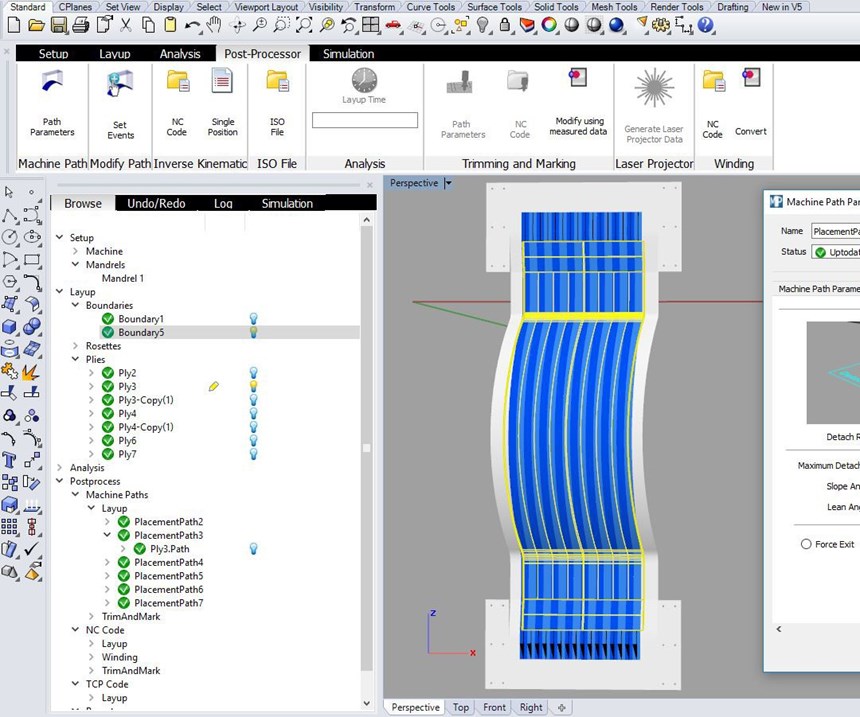

The 2005 release of VERICUT AFP/ATL met Boeing’s requirements as it successfully programmed and simulated Electroimpact (Mukilteo, Wash., U.S.) AFP machines but was customizable to work with other systems. Soon after, the company released its VERICUT Composites Applications with two modules: VERICUT Composite Programming (VCP) and VERICUT Composite Simulation (VCS). VCP reads CAD surfaces and ply boundary information and creates fiber-placement paths to fill the plies according to user-specified manufacturing standards and requirements. Layup paths are linked together to form specific layup sequences and are output as NC programs for the AFP machine.

VCS reads CAD models of the layup tool and fixtures, and simulates the layup sequence directly from NC program files. Tow material is applied to the layup form via NC program instructions in VERICUT’s virtual CNC simulation environment. The simulated material applied to the form can be measured and inspected to ensure the NC program follows manufacturing standards and requirements. A report showing simulation results and statistical information can be automatically created.

Just as the VERICUT composites application family is designed to work with any AFP/ATL machine, VCS can also simulate directly from VCP or from other composite layup path-generation offline programming applications.

Prior to developing software for composites fabrication, CGTech built its reputation through its VERICUT metal machining software, for which Boeing has been a customer since 1989. Another company, the maker of NCSIMUL software now owned by Hexagon Manufacturing Intelligence Division (Boston, Mass., U.S.), also developed its composites manufacturing package on the foundation of CNC machining software. Created in 2014, NCSIMUL Composites focuses on the simulation function in AFP/ATL (as well as filament winding) programming, including NC program analysis, material layup simulation and results analysis.

NCSIMUL added composites manufacturing simulation after a customer asked for the capability to simulate wire winding. Branching into an additive process from CNC machining, the company seized the opportunity and expanded the program to include composite tow layup. “The two technologies were similar, except that the fiber had to be treated as rectangular (that is, accounting for width),” explains Silvère Proisy, general manager for Hexagon’s production software business. “The challenge was to understand how to deposit material, instead of taking it away. We needed to know a lot about the technology the placement head was using.”

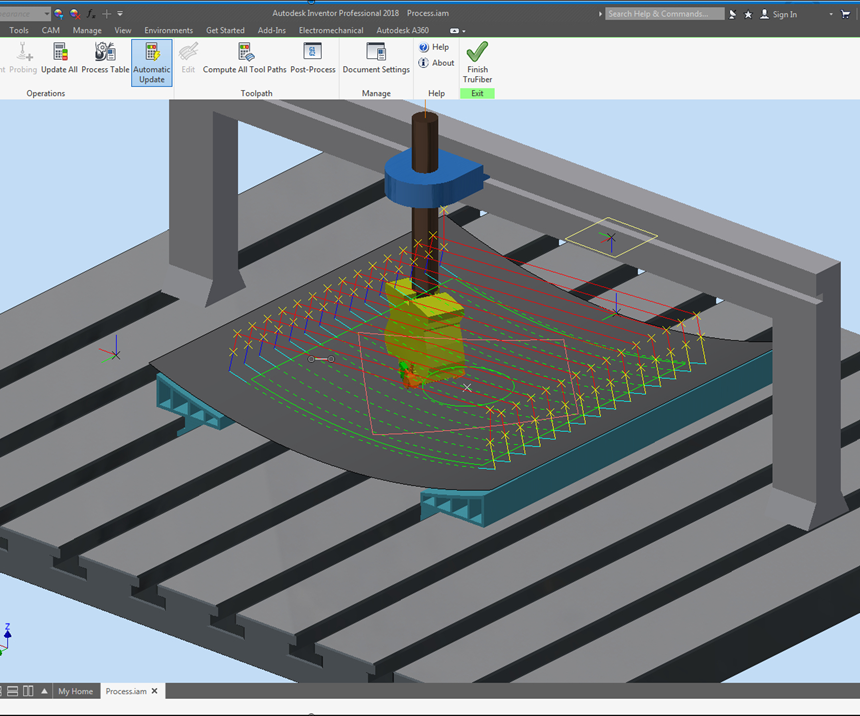

Not all composites fabrication software started with metal machining, though. Instead of working from a CNC software foundation, the TruComposites suite of software tools branched into automated composites manufacturing initially from cutter nesting and laser projection software. The suite, created by Magestic Systems (Westwood, N.J., U.S.) and now owned by Autodesk, includes AFP/ATL-relevant modules: TruPLAN analysis and optimization software, which includes fiber path generation for AFP/ATL applications; and TruFIBER, which optimizes AFP/ATL operational parameters and generates NC codes for manufacturing.

At the time of the 2009 CW feature, Makidea (Prilep, Macedonia) was beta testing its MikroPlace software package, which was written for use with a then-new AFP machine from sister company Mikrosam (Prilep, Macedonia). MikroPlace was modularly constructed from the start, so that it could accommodate other AFPs and ATLs. MikroPlace version 4.0, now offered by Mikrosam, supports filament winding and 3D printing as well as AFP/ATL, and also supports multiple machines or robots working on different aspects of the same project.

These production software developers have emphasized the advantages of machine-independent software, noting that the metal-cutting industry experienced a similar move from software created by the machine tool builder to software developed separately. “What Magestic realized,” Yancey recalls, “is that there was a need for more sophisticated path planning to be used on more than one machine. Our system accounts for different laydown strategies affecting rate and quality. There are tradeoffs involved, and we could look at a design and determine the best machine for the job.”

Colvin agrees that manufacturers are free to select the best machine for a specific part, family of parts or manufacturing process, without having to introduce a different piece of software into the engineering process for each brand of machine. He adds, “When software is separate from the machine and applied in a variety of applications, the software increases efficiency and agility of the overall manufacturing process.”

Of course, some AFP/ATL manufacturers have maintained their proprietary software. Automated Dynamics (Niskayuna, N.Y., U.S.) is one of several AFP/ATL manufacturers that chose to keep software development in-house. The company’s FPM (Fiber Placement Manager), which supports planning, development and simulation of an AFP-built composite structure, and FPS (Fiber Placement Software) automation machine control are Windows-based programs to provide ease-of-use for the proprietary suite. One advantage of proprietary software developed by the machine builder is that all troubleshooting is the responsibility of one supplier. Interestingly, this same split in philosophies exists in the metal machining world: Okuma (Tokyo, Japan) has chosen to build and maintain its own controller and machine programming software for its machine tooling centers.

Whether proprietary or machine-independent, AFP/ATL software is primed for fuller integration with other software systems, working toward a complete digital thread.

Functional data integration

Building out the digital thread in AFP/ATL operations entails integration not only of the manufacturing software modules but of the full product lifecycle, from design to manufacturing and inspection of each component, and ultimately to assembly and MRO (maintenance, repair and overhaul) operations through the life of the final product. The primary challenge to this integration is what the smart manufacturing community refers to “traditionally siloed” functions. That is, design functions have developed and evolved separately from manufacturing functions such that moving information from one to the other is by no means automatic. A fully functional digital thread will erase the communication barriers between functions and make application development a much more streamlined process.

However, there are two factors that make interconnectedness more difficult for the manufacture of composite components than for metal, plastics and other materials. First is that AFP/ATL is still a relatively young technology. Fifteen years may sound like a lot of time for machine-independent AFP/ATL software to have been under development, but it doesn't sound quite so long when compared to CNC software for metal machining operations, which launched in the 1970s and has advanced along with computer technology throughout the subsequent decades. Further, AFP/ATL hardware is still evolving, with a great deal of customization, Colvin notes. “In order to be successful, companies often need customization on the machine to fit their parts and process — every machine has something custom. And everyone’s process is different: different rollers, separate debulks and more.” AFP/ATL software designers must continue to focus on supporting core, common functions as well as adapting to ever-evolving machine customization, perhaps more so than on integrating with other systems.

Second, the relatively large number of variables in composites design and manufacture, due to composites’ anisotropic and heterogeneous nature, has led to more functional silos than for manufacturing with metals and other isotropic, homogenous materials. “With metal cutting, it doesn’t matter how you got there, as long as the part matches the final design,” Colvin says, “but different procedures in composites programming will lead to completely different parts.”

There is an obvious need for communication between functions in the design-manufacture cycle. “If I make a change to aid manufacturing, what effect does that have on design,” Yancey asks, highlighting the kind of data that must be portable in both directions.

Software providers are working diligently toward this end. “We are getting a better representation of what can be manufactured, and going back to ensure it meets design specifications,” Yancey continues. “This is allowing us to reduce overdesign to account for laps and gaps, for example, and to make a lighter weight composite structure.”

Yancey points specifically to Autodesk’s introduction of Fusion 360, a cloud-based common data environment connecting design and manufacturing workflows. Initially, Fusion 360 is supporting CNC machining for manufacturing, “but additive manufacturing is next to be addressed,” Yancey says. This includes AFP/ATL programming as well as 3D printing software. Currently under development at Autodesk is Fusion Production, an additional product that will enable manufacturers to plan, monitor and optimize production performance. Fusion Production creates a digital view of manufacturing processes, from scheduling and dispatching work to tracking and analyzing production and IIoT data.

Similarly, CGTech has partnered with Siemens PLM Software (Plano, Texas, U.S.), integrating VERICUT with Siemens Teamcenter digital lifecycle management software. According to the companies, this integration enables CGTech users to seamlessly interact with technology designed to enhance product development decision making and produce better products. Following historic trends in the same way that Fusion 360 has, VERICUT metal-cutting software is currently being integrated with Teamcenter; CGTech reports that VERICUT Composites software is not yet integrated with Teamcenter.

Ultimately, the goal in smart manufacturing is to completely close the design-manufacturing loop. “There’s a lot of sensor data that today is being used primarily to identify a problem so that you can correct it early in the process,” Yancey says. “The data is there and I think there’s much more we can do with it so that we can improve, and not introduce defects in the first place.”

Yancey expects not only a convergence between design and manufacturing but also a convergence in manufacturing methods. “If we have a robot cutting material, what can we learn from that and apply to a robot laying down material?” He foresees hybrid workflows and greater ability to investigate tradeoffs with different manufacturing methods. All the machine-independent software developers interviewed by CW report a focus on new manufacturing methods — robotics in particular — and opportunities for a hybrid manufacturing approach that brings the best performance attributes of each manufacturing method.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More