Processes

SeaBioComp project develops biocomposite demonstrator products for marine applications

Prototype products explore thermoplastic polymers, natural fibers and 3D printing technologies to effectively reduce the use of fossil-based materials in the marine sector.

Read MoresensXPERT Digital Mold earns 2022 AVK Innovation Award

Data-driven sensor technology optimizes and increases composites manufacturing efficiencies in real time, achieved through collaborative network.

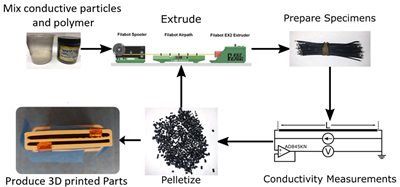

Read MorePatent-pending Purdue process embeds sensor particles, functionalizes 3D-printed structures

Purdue University researchers have developed a novel wet-mixing method to add sensor particles to 3D printer filaments, which will enable manufacturers to create functional printed parts.

Read MoreMikrosam, H2Storage collaborate on 300+-liter Type IV hydrogen tanks

Automated filament winding cell achieving wind speeds of 6 meters/second improves production performance, shortens curing cycle for serial production of 700-bar Type IV tanks.

Read MoreThermoset-thermoplastic joining, natural fibers enable sustainability-focused brake cover

Award-winning motorcycle brake disc cover showcases potential for KTM Technologies’ Conexus joining technology and flax fiber composites.

WatchUniversity of Maine unveils 100% bio-based 3D-printed home

BioHome3D, made of wood fibers and bioresins and entirely 3D printed, highlights Maine’s effort to address the need for more affordable housing.

Read MorePlant tour: Avel Robotics, Lorient, France

From AFP hydrofoils to more efficient aircraft parts, Avel uses digital design, multiprocess production and a rule-breaking approach for complex 4D composites.

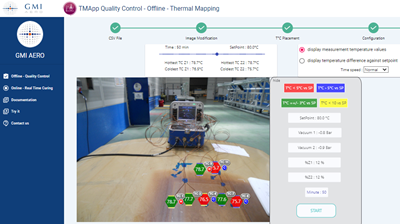

WatchThermal Mapping Application digitizes GMI Aero hot bonder console

The TMApp enables operators to track and visualize the temperature field during composite repair or manufacture in real time using Anita 4.0 and Anita EZ bonding/repair bonder solutions.

Read MoreLimited edition watch features carbon fiber case produced by 9T Labs

Using its Additive Fusion Technology, 9T Labs mass produced 1,000 units of the watch case from continuous carbon fiber-reinforced PEKK, achieving a strong, ultralight, aesthetic product.

Read MoreMetal AM advances in composite tooling, Part 1

Multiple metal additive technologies are gaining market acceptance and interest for composite tooling used in processes ranging from short-fiber injection to autoclave-cure prepreg.

Read More