Processes

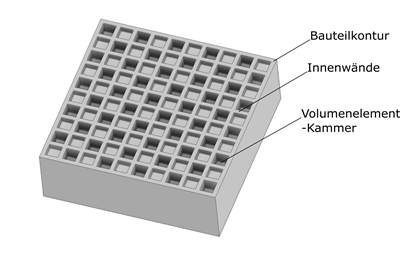

Voxelfill process presented by AIM3D overcomes inhomogeneous strength properties in 3D printing

Through the Voxelfill approach, components are 3D-printed via cross-layer filling versus layered printing, strengthening Z-direction weakness for materials like fiber-reinforced composites.

Read MoreFortify ships Flux Core 3D printer to Ierus Technologies

Novel radio-frequency structures for defense systems are to be designed for and built via Fortify’s Flux Core composite-photopolymer 3D printer.

Read MoreCAMX 2022 exhibit preview: Thermal Equipment Corp.

TEC highlights its range of services and capabilities, including its Off-The-Shelf (OTS) Autoclaves which deliver robustness, quality and reliable performance.

Read MoreBucci Composites presents 20-inch carbon fiber rim dedicated to the aftermarket

The elegant, sporty composite rim design manufactured via HP-RTM targets weight reduction, with key features addressing ease of assembly and high-temperature conditions.

Read MoreCreative Composites Group introduces product upgrades to combat extreme weather, climate change

New StormStrong FRP technologies are engineered for key infrastructure projects that need to exceed standard resiliency specifications.

Read MoreCAMX 2022 exhibit preview: Wickert Hydraulic Presses USA

Wickert Hydraulic Presses showcases its custom hydraulic presses and fully automated press systems for demanding composite manufacturing solutions.

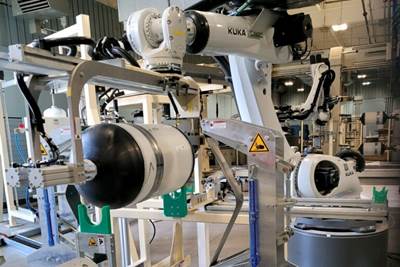

Read MoreAutomated filament winding system increases throughput, reduces manual labor for pressurized well tank production

For its new line of composite well water tanks, Amtrol worked with Roth Composite Machinery on an automated process for faster, more easily tracked production.

WatchVoith H2 storage tanks made with in-house towpreg winding

Plug & Drive H2 storage system displayed at IAA Transportation 2022 uses 700-bar tanks for heavy-duty commercial and construction vehicles.

Read MoreGA-ASI establishes Additive Design and Manufacturing Center of Excellence

New Center focuses on AM applications, R&D, large-scale tooling and next-generation flight hardware to streamline UAS manufacturing.

Read MoreClemson Composites Center leads research in low-cost composite tooling

Innovative technology approach to use additive manufacturing and artificial intelligence to produce tools faster, at a lower cost and with less environmental impact.

Watch