Processes

Covestro, Arcesso Dynamics launch solid-surface manufacturing solution Arfinio

First use of reaction injection molding (RIM) on aliphatic polyurethanes enables complex, lightweight and seamless designs and new property combinations.

Read MoreCygnet Texkimp builds high-precision slitter spooler rewinder for industry trials

Demonstration machine can precisely slit and wind up to 48 tapes from continuous thermoset UD carbon fiber prepreg, with additional material compatibilities.

Read MoreDrawing design cues from nature: Designing for biomimetic composites, Part 1

Biomimicry is an interdisciplinary methodology that can inform composites design and manufacturing via use of more effective and sustainable materials, structural fabrication and technological practices.

Read More9T Labs, Purdue University to advance composites use in structural aerospace applications

Partnership defines new standard of accessibility to produce 3D-printed structural composite parts as easily as metal alternatives via Additive Fusion Technology, workflow tools.

Read MoreLanxess equips SUVs with Tepex dynalite underbody paneling

Robust thermoplastic panels are 30% lighter than steel designs, features higher resistance to stone impacts or other damage, indicating future applications in electric-, hydrogen-powered vehicles.

Read MoreCDZ Compositi introduces patented 3D Flex Composite

Specialist in structural and aesthetic prepreg press parts enhances 3D shaping and flexibility in composite parts using carbon and other reinforcement fibers.

WatchTri-Mack introduces thin, lightweight thermoplastic composite enclosures

Durable, low-cost manufacturing support wide range of industrial uses, with option for embedded EMI shielding.

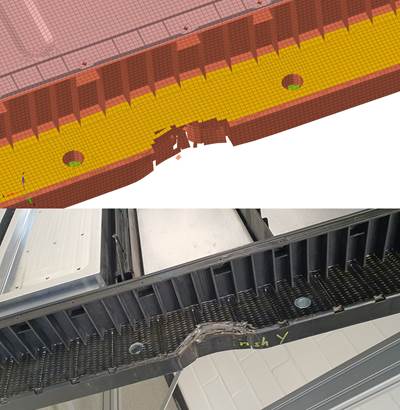

Read MoreBattery enclosure demonstrator testing proves EV feasibility, launches series production projects

Kautex Textron and Lanxess jointly developed and tested a PA6 technology demonstrator, reinforced with locally placed continuous fiber blanks, which passed all important mechanical, thermal tests.

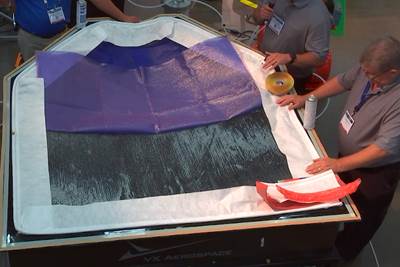

Read MoreDigital Demo: Aerospace Carbon Fiber Infusion

Learn how this process combined with carbon fiber can offer the manufacturer the benefits of increased strength and the ability to make a lighter-weight part.

WatchMighty Buildings completes 3D-printed zero net energy home, expands B2B growth

Fiber-reinforced 3D-printed home incorporating the panelized Mighty Kit system is part of a future community of 40+ units designed to provide environmental and economic benefits.

Read More