Resins

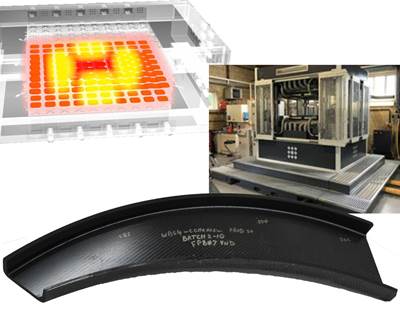

RAPM development with PtFS

Boeing-led program explores rapid part cycles using automated, 180-channel thermal control molding cell for infusion, thermoset prepreg and thermoplastic composites.

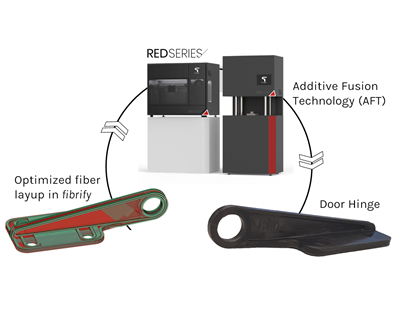

Read More9T Labs, Arkema present new manufacturing approach for small aerospace parts

The companies demonstrate cost-competitive series production of structural composite parts using carbon fiber/PEKK materials and additive manufacturing.

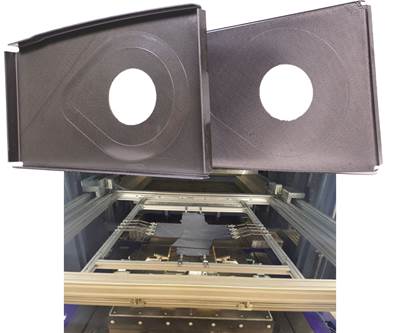

Read MoreNovel prepreg for compression molding in RAPM

Solvay and Boeing combine aerospace performance with process knowledge for high-rate, low-cost composites production.

WatchCurve in the road: First curved pultruded auto parts

Thomas Technik + Innovation KG’s radius pultrusion process unlocks new possibilities for the automotive market and beyond.

Read MorePark Aerospace Corp. introduces mid-toughened epoxy resin system

The E-752-MTS mid-toughened 350°F (177°C) cure epoxy system is designed for primary and secondary aircraft structure applications.

Read MoreThird patent issued for flexible thermoplastic prepreg

Technology enabling wider tapes and easier weaving/braiding for void-free laminates now offered by Precept One LLC

Read MoreWeb Industries launches composite formatting line in France

The U.S.-based precision formatter has installed its first high-volume composite slitting and spooling line at its Omega Systèmes plant in Nantes, France.

Read MoreIDI Composites expands tank farm at North American headquarters

The company expanded capacity for its resin materials tank farm to meet industry needs for its molding compounds and composite materials.

Read MorePolypropylene honeycomb lightens, strengthens automotive panels

Polypropylene honeycomb cores from ThermHex are used by Brazilian OEM DPA Moldados to make the trunk floor of the Hyundai Creta ix25.

Read MoreChemical Process Services Ltd. develops greener epoxy curing agents

The Furalkamines are a new form of Mannich base curing agents said to deliver significantly enhanced cure performance for epoxy resins.

Read More