DPA Moldados automotive panel with polypropylene core. Source | DPA Moldados

Honeycomb cores are not new to the composites industry, but they are relatively new to the automotive composites market, where composite materials are only just starting to migrate into parts and structures for high-volume vehicles.

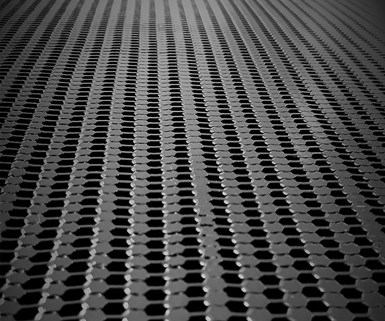

Recognizing this, ThermHex Waben GmbH (Halle, Germany) has developed a polypropylene honeycomb core material for composite sandwich structures in automotive panels. The standard volume weight of this core is 80 kilograms per cubic meter. Also available, for applications that require less compressive strength, is a core with a density of 60 kilograms per cubic meter. Core thickness ranges from 3 to 28 millimeters, with cell sizes of 3 to 9.6 millimeters. The ThermHex honeycombs have a half-opened surface that, in combination with various surface finishes, enables what is said to be an optimal connection between core and skin layer in the subsequent sandwich element. Small cells also enable an almost perfect surface finish.

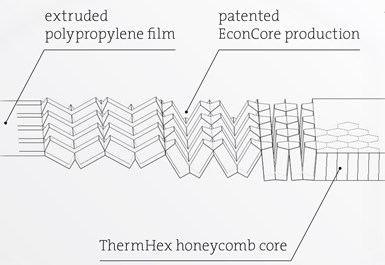

ThermHex/EconCore polypropylene honeycomb core material production process. Source | ThermHex

ThermHex produces its honeycomb cores by extrusion of thermoplastic polymers into a film, rotational vacuum-forming, a folding process and in-line lamination of the surface finish to allow a better bonding of skin layers. This patented, continuous, inline process, in which various skin layers can be applied to the honeycomb core, produces panels that ThermHex customers turn into finished components by applying the appropriate skin layer and forming and cutting them to size. By contrast, ThermHex says, other processes require each layer of honeycomb to be individually cut from a block and then laminated.

Thermoplastic honeycomb in Brazil

Automotive supplier DPA Moldados (Itupeva, São Paulo, Brazil), which fabricates interior trim components, air ducts and thermal and acoustic insulation for various automotive OEMs, has recognized that car manufacturers need alternatives for various monolithic components that are lighter but have similar or better mechanical properties.

ThermHex polypropylene honeycomb core material. Source | ThermHex

Since 2017, DPA Moldados has used the black version of the ThermHex polypropylene honeycomb core, replacing core materials of other producers. The honeycombs are used by DPA Moldados to fabricate, for example, the trunk floor in the Hyundai Creta ix25.

In this application, glass fiber mats are preheated, stacked on the top and bottom side of the ThermHex honeycomb core and then press-molded with a polypropylene resin matrix (granules) into a sandwich structure. According to DPA Moldados, the company is one of the few manufacturers in the world that is technically capable of producing this type of sandwich molded part for mass production. Furthermore, the materials used are 100% recyclable and require less energy to produce than competitive materials.

ThermHex says its honeycomb core helps reduce the weight of automotive components compared to solid materials, with similar or better strength properties.

In addition to the production of automotive components, ThermHex says its honeycomb cores can be found in truck box bodies, marine interiors, swimming pools and furniture. The ThermHex production process is offered worldwide under license by mother company EconCore (Leuven, Belgium) and is used, for example, by Renolit under the name Gorcell for the trunk floors of the Maserati Gihbli and the Jaguar F-Type. In Japan, the technology is marketed by Gifu Plastics under the name Teccell and used there to fabricate the trunk lid of the Toyota Prius.

Related Content

JEC World 2023 highlights: Innovative prepregs, bio-resins, automation, business development

CW’s Jeff Sloan checks in with JEC innovations from Solvay, A&P, Nikkiso, Voith, Hexcel, KraussMaffei, FILL, Web Industries, Sicomin, Bakelite Synthetics, Westlake Epoxy and Reliance Industries.

Read MoreParis Air Show 2023 highlights

The Paris Air Show, one of the largest aerospace trade shows in the world, returned for the first time since 2019 and proved that the global aviation industry industry is very much alive and kicking.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreSyensqo becomes new Solvay specialty materials company

Syensqo represents what was Solvay Composite Materials, focused on delivering disruptive material technologies and supporting growing customer needs.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More