RTM

CAMX 2022 exhibit preview: Polytek Development Corp.

Endurance Technologies brand, Custom Polymer Designs, demonstrates CPD 2110A/9234B capabilities in the Composites One and Closed Mold Alliance Demo Zone, alongside featured Polytek-brand tooling board.

Read MoreCAMX 2022 exhibit preview: Olin Epoxy

Olin Epoxy offers a portfolio of epoxy systems for challenging applications. Litestone, Voraforce and Airstone aim to resolve problems and support customers’ business growth.

Read MoreCAMX 2022 exhibit preview: Composite Alliance Corp.

Composite part design and fabrication is supported through standard and custom solutions with global tooling, machinery and service supplier Composite Alliance Corp.

Read MorePlant tour: ÉireComposites, Galway, Ireland

An in-house testing business and R&D focus has led to innovative materials use and projects in a range of markets, from civil aerospace to renewable energy to marine.

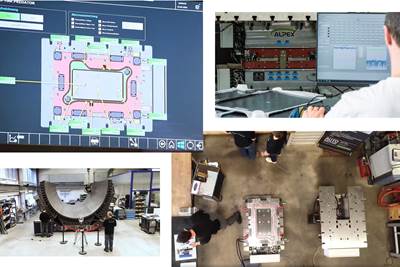

WatchDigitizing tools for composites production

Alpex Technologies focuses on industrialization, process and part intelligence and biocomposites in its next generation of tooling systems.

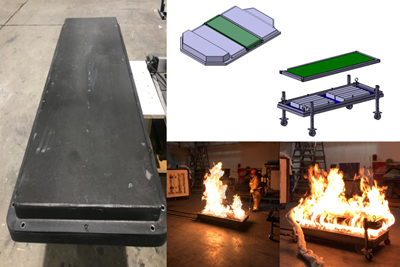

Read MorePrice, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

Read MorePlant tour: Dowty Propellers, Gloucester, U.K.

Transforming decades of design and RTM production reliability into more sustainable, next-generation composite propellers.

Read MoreHexcel joins collaboration program at Spirit’s Aerospace Innovation Centre

Collaborative activities include development of RTM production applications highlighting future opportunities for liquid composite molding.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read More

.jpg;maxWidth=300;quality=90)