Space

What will be the next major iteration in carbon fiber?

A consultant and the president of Dayton, Ohio-based Quickstep Composites, the U.S. subsidiary of Australia-based Quickstep Technologies (Bankstown Airport, New South Wales), Dale Brosius surveys the carbon fiber horizon for signs of what carbon fiber types will be pre-eminent.

Read More2014 SBIR funding solicitations are short on composites

However, the industry should note trends revealed in the areas DoD prioritizes for technology research and transfer.

WatchCheck Out the Competition: Visit the Awards Pavilion at CAMX

If you're headed to CAMX 2014, Oct. 13-16 in Orlando, Fla., be sure to check out the entries in the Awards for Composites Excellence (ACE) and the CAMX Awards — some of which are previewed here.

Read MoreWorld's first all-carbon RV

Built without mechanical fasteners and at approximately half the weight of conventional products, the CR-1 is impressive and designed by an impressive team.

WatchOrbital-ATK marriage a sign of the times?

The merger of Orbital and ATK's Aerospace and Defense groups indicates that companies are positioning themselves to take advantage of the new public/private space market.

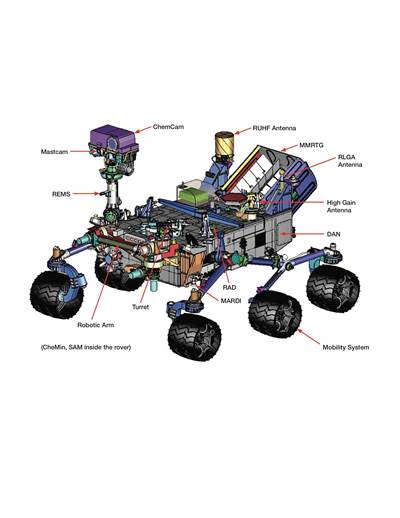

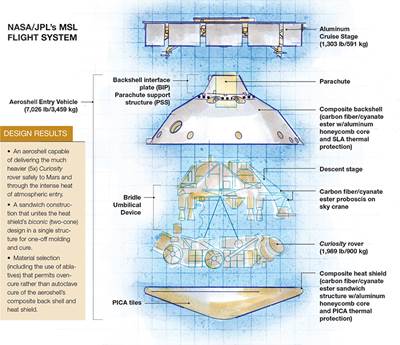

Read MoreThe Curiosity Mars rover: Descent stage composites

Apart from the aeroshell that protected the Curiosity rover during its months in space and Mars descent sequence, only a few other parts of the mission’s descent stage were made from composite materials. Here, HPC identifies and describes them.

Read MoreComposites carry the Curiosity rover to a safe Mars landing

From launch to touchdown, composites performed in flight and stuck the landing!

Read MoreCarbon fiber cryotank angles for a place in launch systems

Boeing has manufactured two carbon fiber cryotanks that are being evaluated by NASA for use in heavy-lift launch systems. They offer 30 weight and 25 percent costs savings.

Read MoreUAVs may deliver Internet access

Facebook is considering use of unmanned aerial vehicles (UAV) to bring Internet access to remote areas. The composites industry could be among the beneficiaries.

Read MoreThe market for OOA aerocomposites, 2013-2022

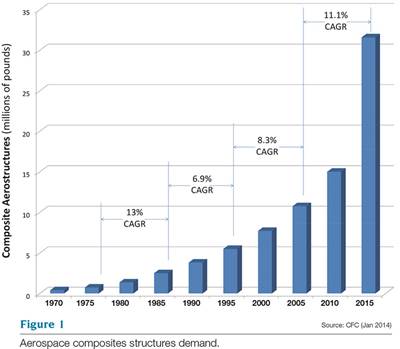

In the coming decade, out-of-autoclave technologies will increase composites penetration into primary flight structures.

Read More