Space

Out-of-autoclave prepregs: Hype or revolution?

Oven-cured, vacuum-bagged prepregs show promise in production primary structures.

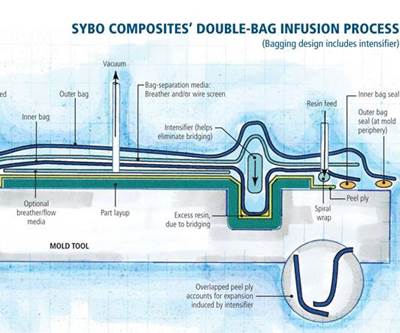

Read MoreDouble-bag infusion: 70% fiber volume?

A double vacuum-bag system and tight process control enable repeatable fiber volumes of 60 to 70 percent and improves consistency of infused laminates.

Read MoreFuture multifunctional structures: Composites needed

Barton Bennett (Odyssian Technology, South Bend, Ind.) discusses multifunctional systems that will soon integrate composite structures with sensors, mechanisms and subsystems.

Read MoreBuilding on CCM lessons learned

Knowledge gained during NASA's composite crew module (CCM) program, a sidelight to the Orion space capsule program, now benefits private space efforts.

Read MoreThe Private Space Race

NASA passes the development torch to legacy contractors and NewSpace entrepreneurs, igniting a new competition in space transport.

Read MoreInterior innovation: The value proposition

OEMs and Tier suppliers ask materials and molding processes to go “green” and do more for less.

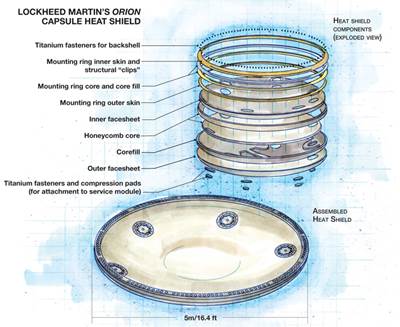

Read MoreOrion re-entry system: Composites displace metal

World’s largest heat shield updates metal design with out-of-autoclave process.

Read MoreCost-effective carbon composite reflector dish

Modular manufacturing method forms different dish sizes with near mirror-perfect reflective surfaces, without resort to one-off tools.

Read MoreAdvanced Composite Cargo Aircraft proves large structure practicality

Dr. John Russell reports that the successful completion of a flying aircraft in the the Advanced Composite Cargo Aircraft program has demonstrated the holistic impact that composites technology can have on future aircraft development.

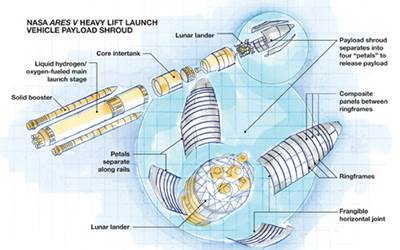

Read MoreOptimizing the Ares V payload shroud

Sizing software allows rapid analysis of candidate composite architecture for highly loaded and weight-sensitive launch vehicle component.

Read More