Space

SAMPE 2013 at a glance

A list of events planned by SAMPE (as of April 1) at its 2013 SAMPE Conference and Exhibition, in Long Beach, Calif.

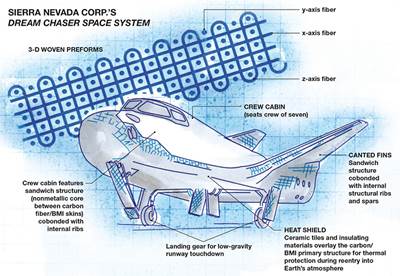

Read MoreU.S. crew and cargo candidate takes shape with composites

Crew-capable Dream Chaser to enable ISS transport missions from U.S.

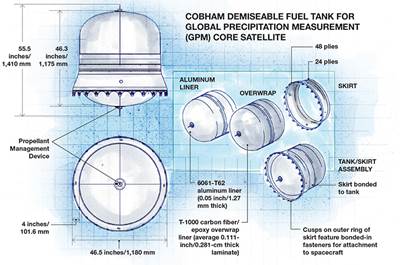

Read MoreGPM mission: Better climate data

Global Precipitation Measurement (GPM) is an international satellite mission designed to provide next-generation observations of rain and snow worldwide every three hours.

Read MoreSpace mission maximized via minimized survivability

CFRP design and manufacturing flexibility prove key in first spacecraft fuel tank designed to disintegrate upon reentry for improved mission efficiency and debris mitigation.

Read More2012 Farnborough International Airshow Report

The biennial U.K. air event delivered the clear message that the aerospace industry — and aerospace composites with it — continue to soar.

Read MoreSAMPE 2012 Report

The Society’s return to Baltimore is a boost to the advanced materials community and an occasion for interesting industry buzz.

Read MoreThe first commercial Type V composite pressure vessel

Composites Technology Development's first commercial tank in the Type V category presages growth of filament winding in storage of compressed gases.

Read MoreNear commercialization: CNT yarn, tape and sheet

Michael R. LeGault reports on progress toward first commercialization of carbon nanotube yarn-, tape- and sheet-type reinforcements for composites.

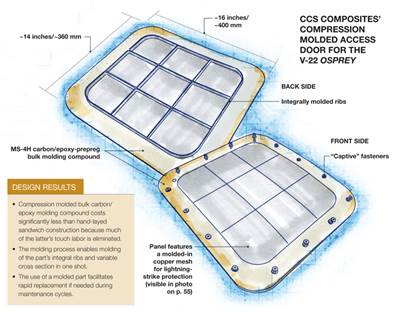

Read MoreRedesigning for simplicity and economy

Military OEM makes the switch from sandwich construction to compression molding to optimize composite aerospace part.

Read MoreSelf-deployable, composite satellite boom

Researchers design and validate a boom made of ultrathin carbon-fiber/epoxy laminate, using a novel, highly accurate analysis method.

Read More