Materials Testing

Low-density SMC: Better living through chemistry

Proprietary sizing, special glass roving and microspheres strip 9 kilos of weight from Corvette body panels.

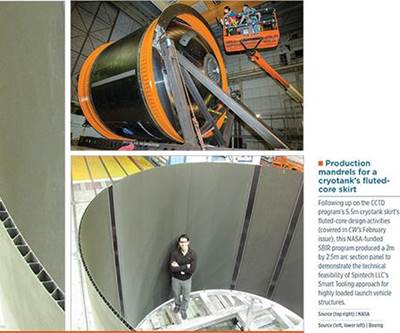

Read More“Smart tooling” cuts time and risk for complex unitized composite structures production

One-piece bladder tooling helps to actualize NASA/Boeing’s revolutionary fluted core design for next-gen cryogenic fuel tank skirt.

Read MoreAlternative precursor R&D: What are the alternatives to PAN?

Carbon fibers made from other precursors are in use, commercially, and many more precursor alternatives have been investigated.

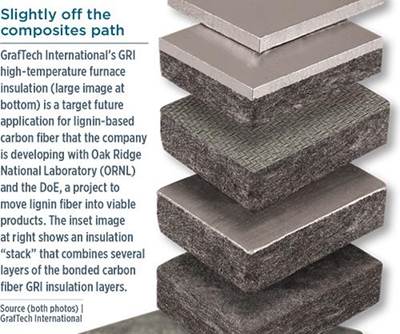

Read MoreAlternative precursor R&D: First commercial use of lignin carbon fiber?

GrafTech International (Independence, OH, US) is working with Oak Ridge National Laboratory (Oak Ridge, TN, US) and the US Department of Energy’s Advanced Manufacturing Office to develop lignin fiber manufacturing and demonstrate it in viable products.

Read MoreAlternative precursor R&D: Oak Ridge National Laboratory

Oak Ridge National Laboratory (ORNL, Oak Ridge, TN, US) has been at the forefront of North American research into alternatives to the polyacrylonitrile (PAN) precursor used to make aerospace-grade carbon fiber.

Read MoreFiber patch preforms help tailor kiteboard performance

Automated means for laying fiber only where needed offers new potential to fine-tune torsional stiffness and flexibility to board and rider styles.

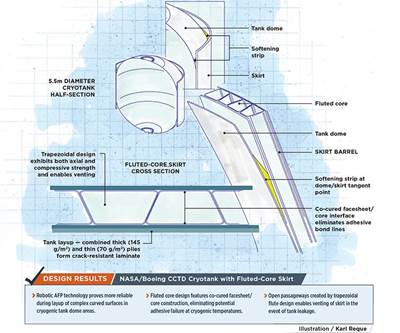

Read MoreNASA/Boeing composite launch vehicle fuel tank scores firsts

Subscale 5.5m-diameter cryogenic tank demonstrator with innovative fluted-core skirt is formed via robotic AFP and cured out of the autoclave.

Read MoreAdvanced composites — An idealized future

A CW columnist, a composites industry consultant and the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (Knoxville, TN, US), Dale Brosius imagines an ideal future for our industry then challenges us to make it real.

Read MoreCompoSIDE and Trace: Game-changer for development of composite parts

Structural design challenges (delamination, coupling and shape distortions, resin-driven failures, local stress concentration and the like) are inherent in laminate architecture. The author's contention is that a solution can be found in design simplification afforded by the work of Dr. Stephen Tsai in Trace-based analysis.

Read MoreTop composites blog articles of 2015

Blog articles about additive manufacturing, 777X composite wings and colored carbon fiber all generated your interest in 2015.

Read More

.jpg;maxWidth=300;quality=90)