Materials Testing

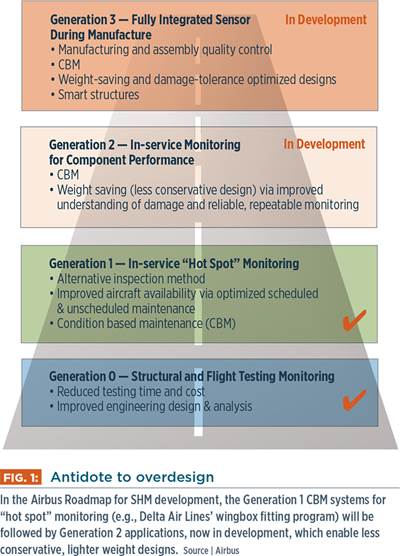

Structural health monitoring: Decades of demos build confidence

Current momentum in local structural health monitoring development can be credited to a great deal of developmental effort on the part of these system developers.

Read MoreDesigning with composites: Optimizing for performance and manufacturing

David Leigh Hudson, the director of product and market strategy for the Fibersim product portfolio at Siemens PLM Software (Waltham, MA, US), the need in the field of composite part design for a serious commitment to what he terms "concurrent engineering" processes.

Read MoreShelby GT350R features carbon fiber wheels

Ford worked with Australia-based Carbon Revolution to develop the one-piece all-carbon fiber wheels, which save 60 lb in weight but provide better steering response.

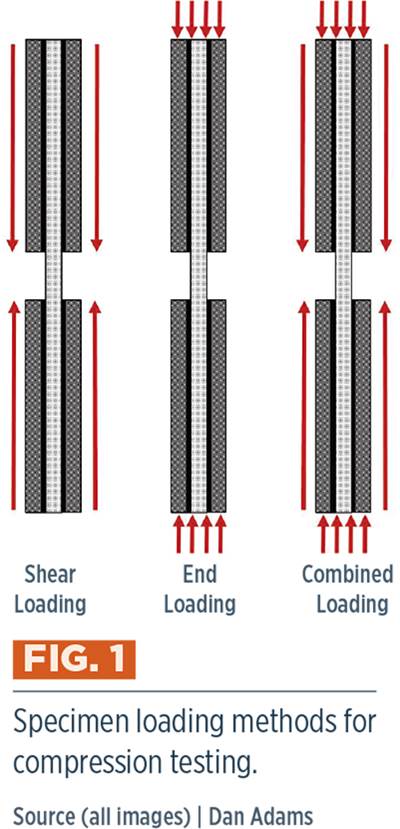

Read MoreOptimum unidirectional compression testing of composites

Dr. Daniel O. Adams, a professor of mechanical engineering, the director of the Composite Mechanics Laboratory at the University of Utah, and VP of Wyoming Test Fixtures Inc. (Salt Lake City, UT, US) discusses the complex relationship between composite tensile and compressive properties, why that makes it necessary to perform both tension and compression testing, and how best to perform the latter.

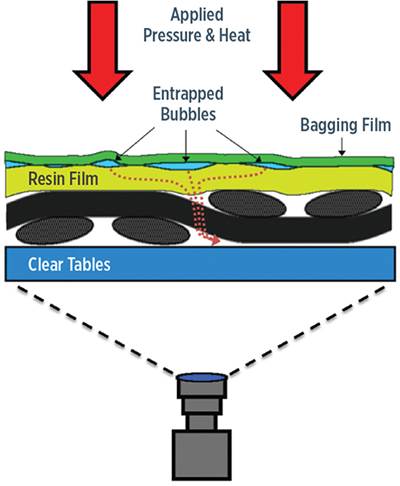

Read MoreOut-of-autoclave processing: <1% void content?

Research sheds light on air and air-bubble behavior in OOA aerospace prepregs.

Read MoreVirtual process chain + online process monitoring = first-time-right manufacturing

Co-authors Dr. Michael Bruyneel, Marc Attar and Dr. Christian Brauner (Siemens PLM Software, Liège, Belgium) illustrate the benefits of manufacturing simulation software in virtual trials of molding processes, using resin transfer molding as a reference.

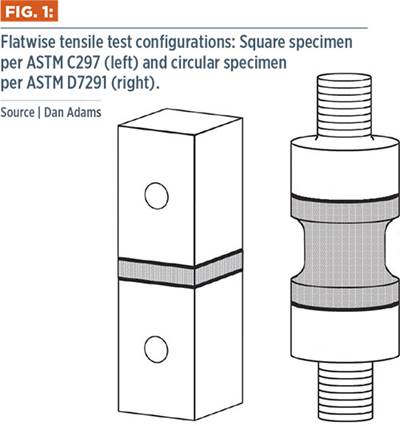

Read MoreMethods for interlaminar tensile testing of composites: A comparative evaluation

Dr. Daniel O. Adams, professor of mechanical engineering and director of the Composite Mechanics Laboratory at the University of Utah and VP of Wyoming Test Fixtures Inc. (Salt Lake City, UT, US) compares and contrasts the direct and indirect loading methods for interlaminar tensile testing of composites.

Read MoreIntegrating NDI into manufacturing: Online inspection of CFRP prior to cure

Esmeralda Cuevas, head of NDT technologies at Tecnatom SA (San Sebastian de Los Reyes, Spain), details efforts of the TARGET project, which investigated how to integrate NDI into the composites manufacturing process prior to cure stage.

Read MoreLooking for Lindberghs

Every paradigm-shifting invention throughout human history has been met with skepticism. CW editor-in-chief Jeff Sloan says the composites industry has need of those willing to attempt what most believe impossible.

Read MoreIncremental thinking just won’t cut it!

Composites industry consultant and regular CW columnist Dale Brosius says if this industry is to have a future that goes anywhere profitable, then we've got to get off the road we're on and map out a whole new way to think about the tasks at hand.

Read More

.jpg;maxWidth=300;quality=90)