CompoSIDE and Trace: Game-changer for development of composite parts

Structural design challenges (delamination, coupling and shape distortions, resin-driven failures, local stress concentration and the like) are inherent in laminate architecture. The author's contention is that a solution can be found in design simplification afforded by the work of Dr. Stephen Tsai in Trace-based analysis.

The development of composite parts and products is generally characterized by extensive design and testing requirements when compared to plastic or metal equivalents. Composite materials and related engineering activities are regarded as inherently complex. It is generally true that these activities require advanced knowledge, tools and experience that, sometimes, are inaccessible. Yet there is strong market demand for high-strength and lightweight composite components, leading to continuous research and development activities to meet growing demand and overcome developmental barriers.

Designers have to deal with these complexities, which include multiple variables, anisotropic properties and ply-based material architecture. And the complexity goes to the next level when it comes to processing and manufacturing.

Most of today’s composites industry works with thick plies layered in composite laminates. This practice presents a lot of tough challenges in manufacturing and design activities. Ply stacking sequence management and complex parts manufacturability could be mentioned, among others. A lot of structural design challenges, such as delamination, coupling and shape distortions, resin-driven failures, local stress concentration, etc., are also inherited from laminate architecture. There are a lot of efforts in the industry to address these limitations and find better solutions. Our contention is that the real solution could be found in simplification and that the industry has to look at the problem differently.

In 2015, I teamed with Professor Research Emeritus of Stanford University Dr. Stephen Tsai to evaluate and apply his Trace approach into CompoSIDE’s (Cowes, Isle of Wight, UK) composite design and analysis platform. Trace is, in essence, a simple invariant of tensorial transformation in matrix algebra and is a fundamental parameter for composite materials. The research revealed that stiffness and strength data for all modern carbon fiber/polymer composite laminates converge to almost identical values if normalized by their respective stiffness trace. This universal stiffness means that a master ply and simple scaling by means of material trace can be used to dimension laminate parts, just like they can for homogeneous materials. (Master ply is trace-normalized material which is shared for CFRP materials and the trace of this material is equal to 1. See "Overnight design allowables? An invariant-based method for accelerating aerospace certification testing" under “Editor's Picks,” at top right). This is a truly powerful discovery.

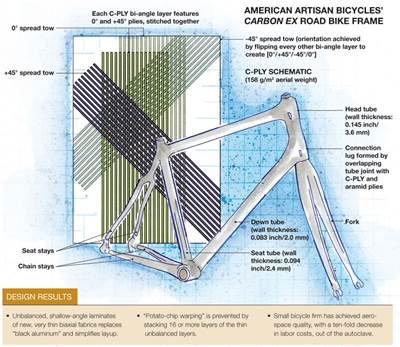

Following a call for a pilot project in 2014, Tsai and CompoSIDE held collaborations with textile manufacturer Chomarat (Le Cheylard, France), which resulted in the practical development and commercialization of the latter’s trademarked C-Ply carbon composite reinforcements, which feature thin plies, off-axis angles and non-crimp fiber (NCF) material, resulting in stronger, lighter and homogeneous composite structures. This first project led to successful validation of the Trace theory and associated development methodology (see "Bi-angle fabrics find first commercial application" under “Editor's Picks”).

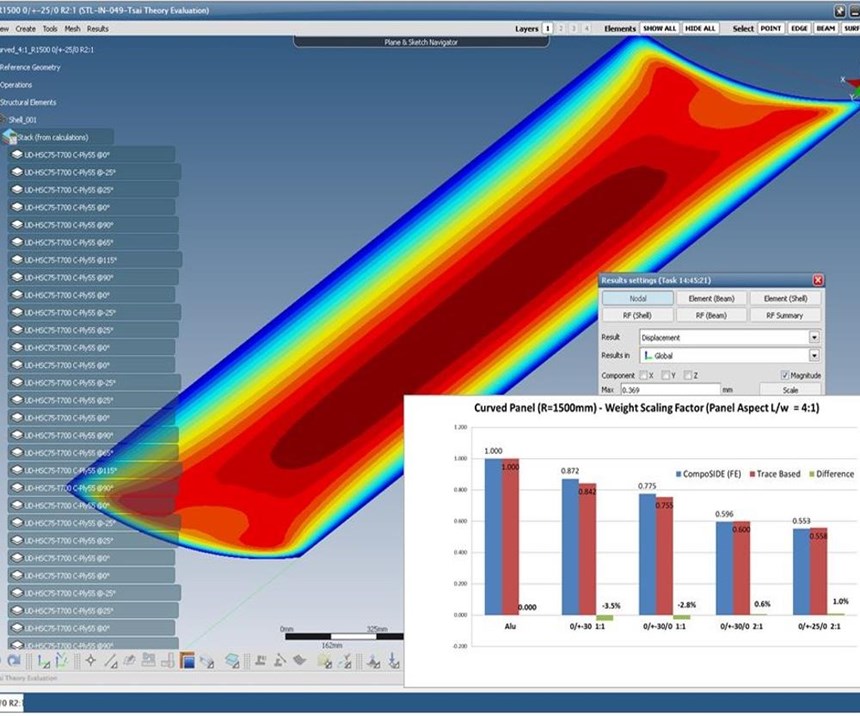

To prove the benefits of this new theory, CompoSIDE conducted a series of studies benchmarking the Trace-based design approach to CFRP composites and compared the results with those obtained from standard FE modeling, using CompoSIDE’s FESpace modeling capabilities.

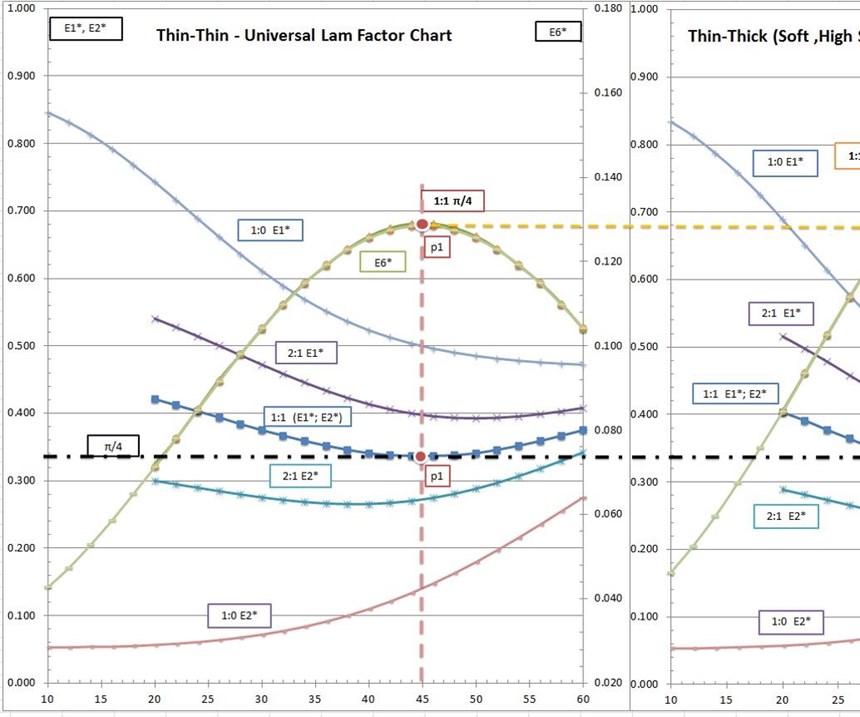

Flat and curved composite panels with different laminate configurations were designed. More than 25 design options were investigated, including single-skin and sandwich designs. Material Trace Value, Universal Laminate Factor Charts (see Figs. 1 & 2, at left) and simple scaling functions were used to find alternative designs and to quantify weight savings compared to a baseline panel.

The outcome of this benchmark was very promising. The results from trace-based scaling for both curved and flat panels correlated well with the FE results. The discrepancy in most cases was less than 3.5%.

Engineers were quite impressed with how efficiently they could evaluate alternative options. Having solved one boundary problem for reference design, an engineer is able to replace either the material or even the entire laminate without rerunning additional FE modeling. Using scaling with the material trace and laminate factors would yield a good answer in most cases, especially in an early design phase. This could save a lot of time in design feasibility and trade studies.

A similar approach can be used for strength design, using either trace-normalized master strain-stress templates, which define the uniaxial tensile and compressive strain failures or by adoption of the OMNI or the Unit Circle Failure envelopes for all common ply angles laminates. Based on professor’s Tsai and D. Melo’s work, strength envelopes for these laminates could converge to one interactive Unit Circle Failure criterion, which allows further simplification in the approach to the strength prediction.

The adoption of an idealized single-value construction makes the results, either represented by failure index or strength ratios, scalable. This is very powerful and allows adoption of very efficient optimization routines, such as Direct Weight and Layup Rate methods in composite design workflows as described by Professor Tsai.

In practical applications using CompoSIDE and the Trace-based design scaling model, engineers can evaluate a first-design candidate based on the generalized response and applying Trace to understand not only if there is a possible failure, but also how far, or how close, the material is to the failure point. This additional information is extremely valuable and adds a new dimension to the design phase, allowing much simpler optimization: We are able to obtain qualitative and quantitative data to guide us in the design process and facilitate product development even in an early stage of the development.

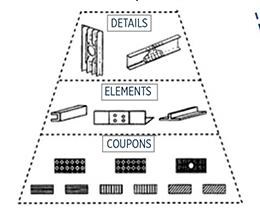

As part of the development and design process, Trace-based design elements also can be applied to material and components testing and characterization programs. Traditional testing pyramids can be replaced with much simpler test programs, greatly reducing the cost and time associated with materials testing, thus reducing development costs (see Fig. 3, at left).

A practical example would be the testing of a simple composite structural panel. The testing procedures would generally require a full characterization of materials considered for the design, using multiple tests and laminate configurations. This can lead to approximately 35 coupons per material, making the testing procedures costly and time-consuming.

Using the Trace-based approach, we can significantly increase the number of tested material and laminate configurations while reducing the total number of test specimens. Only uniaxial testing is required to characterize material. If we know axial properties, trace and other properties can be derived from the universal master material definition.

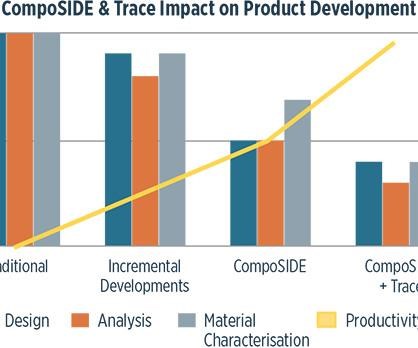

In conclusion, Trace-based scaling is a very powerful and efficient tool. It accelerates design and testing procedures for composite materials and parts almost exponentially. Trace theory, combined with CompoSIDE’s modeling software, can facilitate the development of new composite applications while reducing the development times and costs (see Fig. 4, at left).

Working with the Trace dimensionless laminate parameters and material has proved to be incredibly fast and intuitive, combining qualitative and quantitative data that open new doors to understanding composite designs, making comparison of material or laminate performance almost immediate. The selection of alternative materials and laminates is visual and very efficient, and alternative solutions can easily be tested at reduced cost.

Related Content

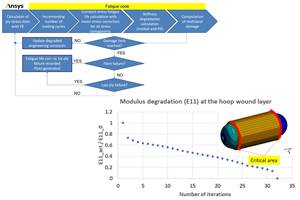

Numerical tool with mean stress correction demonstrated for fatigue life estimation of thermoplastic composites

To aid design of fatigue-resistant structures, Econ Engineering has developed an algorithm to evaluate ply-based cyclic stiffness degradation combined with an FE failure check, validated for a CF/PAEK pressure vessel.

Read MoreComposite sidewall cover expands options for fire-safe rail components

R&D project by CG Rail explores use of carbon fiber-reinforced thermoplastics and recycled manufacturing scrap to meet fire safety, weight and volume targets.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreHeat mapping simulation to improve AFP parts

An optical model developed for Coriolis Composites’ SimuReal AFP process simulation software enables verification of energy distributions during AFP to better define heating laws.

Read MoreRead Next

Overnight design allowables? An invariant-based method for accelerating aerospace certification testing

Dr. Stephen Tsai, professor research emeritus in the Department of Aeronautics & Astronautics at Stanford University, suggests a way to accelerate certification testing via “overnight design allowables.”

Read MoreBi-angle fabrics find first commercial application

Bicycle manufacturer sees dramatic productivity gains using unbalanced fabrics conceived at Stanford University and manufactured by Chomarat.

Read MoreModeling and characterization of crushable composite structures

How the predictive tool “CZone” is applied to simulate the axial crushing response of composites, providing valuable insights into their use for motorsport applications.

Read More

.jpg;maxWidth=300;quality=90)