Thermoplastics

Boston Materials expands into hydrogen fuel cells market with ZRT lightweight bipolar plates

In collaboration with Arkema, Boston Materials introduces its high-performance, recyclable material for boosting fuel cell performance and lowering costs.

Read MoreStrohm and Petronas join forces to commercialize thermoplastic composite pipes

Strohm says the agreement will be instrumental in expanding knowledge of the design, production and qualification standards of its TCP products for the replacement of metallic pipes.

Read MoreCycling forward with bike frame materials and processes

Fine-tuning of conventional materials and processes characterizes today’s CFRP bicycle frame manufacturing, whether in the large factories of Asia or at reshored facilities in North America and Europe. Thermoplastic resins and automated processes are on the horizon, though likely years away from high-volume production levels.

Read MoreSaint-Gobain, Roctool join efforts to boost composite 3D textile preform parts manufacturing

3D automated knitted preform layup technology and heat and cooling technologies for additional curing efficiency open a new window of application opportunities for composite and thermoplastic parts.

Read MoreAthletic shoe developed with repurposed thermoplastic waste

Manufactured via a single-step molding process, Decathlon’s Traxium Compressor soccer cleats propel the sporting goods market toward more recyclable solutions.

WatchMitsubishi Chemical Advanced Materials, AMAC cooperate on thermoplastics business in Europe

Partnership to strengthen and develop sustainable composite business activity internationally, includes opening of KyronTEX textile production line in Germany.

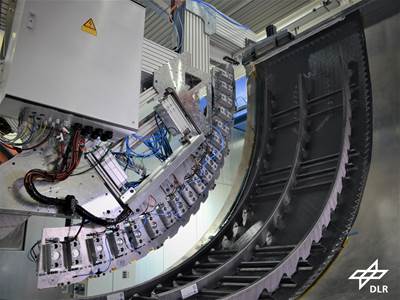

Read MoreDLR Augsburg integrates sixth frame to upper half fuselage test shell for MFFD

Clean Sky 2 thermoplastic composite demonstrator advances toward full assembly.

Read MoreDLR Institute of Structures and Design releases video on TB-Rumpf welded thermoplastic composites

Autoclave-free consolidation and resistance welding validated for future aircraft thermoplastic composite fuselage.

WatchEconCore, Flaxco reveal flax fiber-reinforced thermoplastic honeycomb panels

Natural fiber sandwich panels are expected to replace those made from glass and carbon fiber, offering enhanced rigidity and sustainability for applications in automotive and sporting good markets.

Read MoreSafran joins the ThermoPlastic composites Research Center

The aerospace group joins as part of the ongoing initiative to decarbonize aviation. Safran believes thermoplastic technology development acceleration is a key target to meet this goal.

Read More

.jpg;maxWidth=300;quality=90)