Thermoplastics

Collins Aerospace demonstrates new thermoplastic composites capabilities

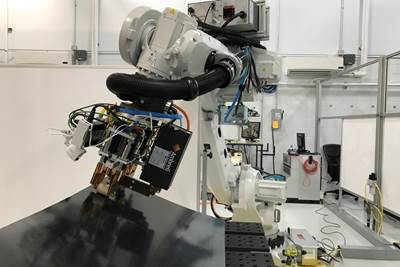

Collins Aerospace in Almere has produced a 7-meter raceway for the Clean Sky 2 MFFD lower fuselage using novel CCM and tooling technology while the Riverside facility in the U.S. advances AFP and welding as part of global strategy for more sustainable airframes.

Read MoreCAMX 2022 exhibit preview: Collins Aerospace

Collins Aerospace identifies its extensive thermoplastics portfolio, including the display of an aircraft nacelle’s integrated curved stiffener and upper and lower longerons.

Read MoreXenia Thermoplastic Specialties launches new range of supertough carbon fiber composites

New XECARB ST family of carbon fiber-reinforced thermoplastic composites combines advanced lightweighting with superior impact strength.

Read MoreCAMX 2022 exhibit preview: Propex Furnishing Solutions

Propex Furnishing Solutions reveals its newest developments in self-reinforced composite technology including polymer-based Curv, Curv Tactical thermoplastic composites and Curv-on-Core technology.

Read MoreCAMX 2022 exhibit preview: Composite Alliance Corp.

Composite part design and fabrication is supported through standard and custom solutions with global tooling, machinery and service supplier Composite Alliance Corp.

Read MoreCAMX 2022 exhibit preview: Qarbon Aerospace

Qarbon Aerospace exhibits its capabilities in manufacturing composite components and assemblies, highlighting its proficiencies in major assembly and systems integration, automated layup, hand layup, high-temp composites and core fabrication.

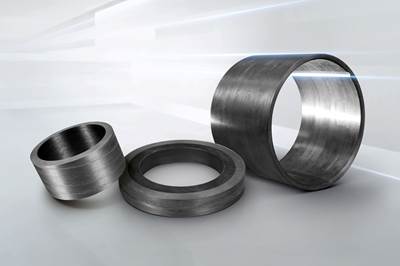

Read MoreProtecting EV motors more efficiently

Motors for electric vehicles are expected to benefit from Trelleborg’s thermoplastic composite rotor sleeve design, which advances materials and processes to produce a lightweight, energy-efficient component.

Read MoreCAMX 2022 exhibit preview: Teubert

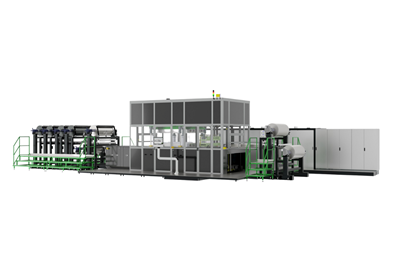

Teubert highlights enhancements made to its continuous compression molding (CCM) system, including production scale-up, reducing required energy during production, live measurement of pressure distribution.

Read MoreFlexible, induction-based heating for thermoplastic composite part repair

Spinning off from a German Aerospace Center (DLR) research project, msquare GmbH’s technology aims to innovate and enable repair for high-temperature thermoplastics.

Read MoreTrelleborg launches low-friction thermoplastic composite bearing

The HiMod Advanced Composite Bearing Plus is a dual-layer bearing with a low-friction PEEK liner that doubles as an impermeable sealing surface, in addition to 50% less sliding friction, increased wear performance.

Read More

.jpg;maxWidth=300;quality=90)