Thermoplastics

CAMX 2020 Preview

Transformed into a virtual event, the latest CAMX 2020 preview describes some of the opportunities that will be available for visitors and exhibitors.

Read MoreElectroimpact’s 6-axis continuous fiber 3D printer, one part of future multi-functional manufacturing cell

The Scalable Composite Robotic Additive Manufacturing (SCRAM) system 3D prints with continuous fiber tape or filament and seamlessly swaps end effectors for large-scale pellet deposition and CNC machining.

WatchArevo launches direct-to-customer 3D-printed bicycle

The Superstrata brand features a fully unibody carbon fiber/polyamide frame manufactured using Arevo’s direct deposition additive manufacturing process.

Read MoreKordsa expands thermoplastic prepreg lineup

The new woven prepregs are offered with polypropylene or polyamide resin matrices in sheets up to 1.2 by 1.2 meters.

Read MoreLanxess presents thermoplastics for automotive applications

The company is showcasing use of its composite materials in A-pillar automotive structures and electric vehicle charging applications at the VDI Congress PIAE virtual event in July.

Read MoreComposites 4.0: Digital transformation, adaptive production, new paradigms

An evolving landscape of automation, sensors and AI software is not an end, but a means to achieve the cost, quality, efficiency and agility required for future manufacturing.

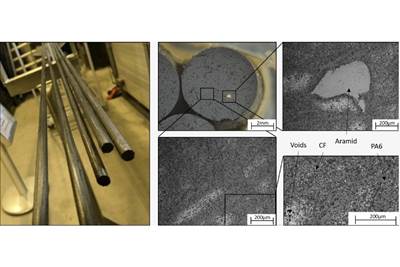

Read MoreFLOTANT project to develop composite mooring cable system for deep water wind farms

Project partners are testing pultruded carbon fiber/thermoplastic profiles for use in a more cost-efficient, robust offshore wind farm mooring system.

Read MoreAimplas-led project develops thermoplastic prototypes

The RECONTRANS project adapts Arkema’s Elium thermoplastic resin for car, truck and rail applications.

Read MoreDSM introduces new UHMWPE fiber

Compared to DSM’s original Dyneema thermoplastic fiber products, Trosar addresses a wider range of high-performance applications.

Read MoreBio-based hybrid tapes assessed for lightweight applications

A project of AZL’s partner institute, ITA, integrates flax fiber reinforcement with a PA11 resin matrix. Targeted end markets include automotive and wind energy.

Read More

.jpg;maxWidth=300;quality=90)