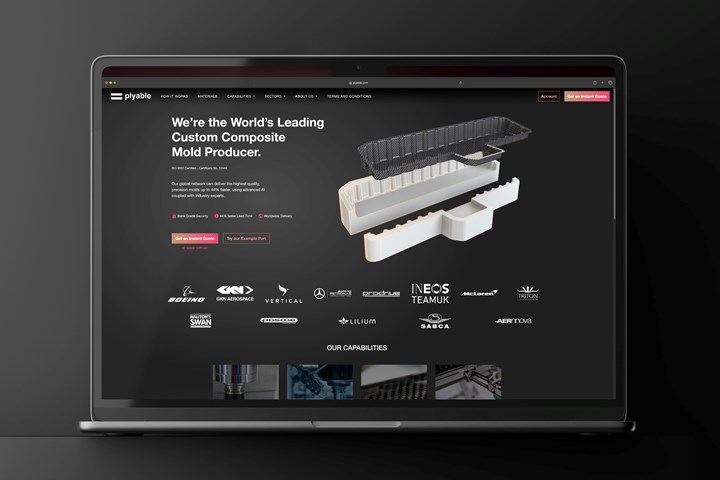

Plyable releases AI-powered mold design tool

Plyable continues to rid composites engineers of workflow bottlenecks through an end-to-end automated system — from mold design to quotation to manufacturing fulfillment.

Plyable (Oxford, U.K.) announces the development of a fully automated mold design process, reducing the labor-intensive step between component design and manufacturing.

The AI-powered mold design tool has the ability to quickly and accurately quote mold manufacturing costs based on designs, a task that currently requires engineering expertise. Days and hours of work can be compressed into minutes, releasing engineers to focus on value-add design work; Plyable cites 44% faster delivery results.

Plyable customer, Sam Pellows, managing director at SR Structures, notes that Plyable’s tool reduces lead times and engineering hours for much of its work, which is to manufacture composite components for applications from grand prix sailing yachts to naval vessels

Notably, the automated mold design process works from any .STEP file and enables design, quotation and fulfillment of precision mold manufacturing to be managed in one seamless process from plyable.com. This recent innovation supplements Plyable’s global network that allows engineers to access manufacturing in 20 countries across 1,500 three- and five-axis machines to ensure every job is matched to the best supplier to meet the engineering challenge, material, tolerance, size or lead time. This global network of quality-assured partners means precision molds can be expedited and delivered in a far quicker and more competitive way than the traditional reliance on a small handful of local suppliers, Plyable points out.

“Plyable was founded on the objective to shift away engineering in high-performance areas — from passenger aircraft and submarines to Formula 1 cars — from a slow and analogue reliance on traditional mold manufacturing,” Martin Oughton, Plyable CEO, says. “We’ve achieved that by building an international network of high-caliber tooling manufacturers accessible from plyable.com to deliver speed, precision and cost-effectiveness. Now, we are taking the next step in this journey by embracing AI to rid design engineers of another bottleneck in their workflows — the mold design process.”

Plyable’s service is live and available to customers at plyable.com; company representatives are demonstrating the solution at JEC World 2024.

Related Content

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Numerical tool with mean stress correction demonstrated for fatigue life estimation of thermoplastic composites

To aid design of fatigue-resistant structures, Econ Engineering has developed an algorithm to evaluate ply-based cyclic stiffness degradation combined with an FE failure check, validated for a CF/PAEK pressure vessel.