Videos

Swoop Aero strengthens partnership with Quickstep Holdings

Next-generation urban aircraft developer expects to scale up its manufacturing capabilities into 2022, which includes the development of composite parts.

WatchAirbus foresees demand for 39,000 new passenger, freighter aircraft by 2040

Retirement of older aircraft to accelerate demand will be progressively driven by replacement, supporting the industry’s decarbonization objectives.

WatchEmbraer unveils four Energia concept aircraft for net-zero aviation by 2050

Aircraft being developed span 9 to 50 seats and electric, hydrogen fuel cell, dual-fuel gas turbine and hybrid-electric propulsion.

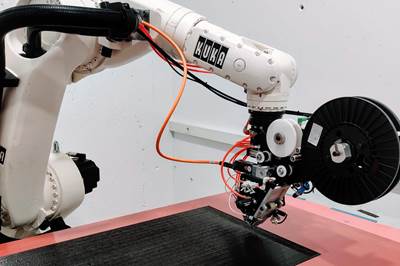

WatchCompoxi installation widens AFP-XS technology application domain

Compoxi aims to characterize and qualify the AFP-XS and new materials for adoption in the growing Space and New Space markets.

WatchPultron Composites advances marina construction with innovative GFRP waler

The waler incorporates a GFRP thru-rod and nut system, delivering high flex and fatigue resistance and increased environmental and aesthetic longevity.

WatchBoeing ecoDemonstrator tests recycled carbon fiber sidewalls, acoustic upgrades for aeroengines and more

Eight aircraft since 2010 have demonstrated new technologies to reduce noise, improve efficiency and minimize aviation’s environmental footprint, with potential impacts for future wings, interiors, engine nacelles and vertical tail design.

WatchMVP releases new model of RAM system for thermoset materials

New large-format AM machine model, RAM 48, maximizes production efficiency and enables custom build dimensions when fabricating thermoset materials.

WatchThe future of composites in wind, hydrogen applications: CW Trending Episode 5

In this episode of CW Trending, Hexcel's Claude Despierres discusses current and future demands for composite materials, especially carbon fiber, in the wind energy industry, as well as supply, cost and performance of these materials in the hydrogen storage market.

WatchLockheed Martin opens hypersonic strike production facility

Lockheed Martin’s 65,000-square-foot Hypersonic Missile Assembly Building 4 (MAB 4) integrates digital transformation advancements for training and virtual inspections.

Watch2021 CW Top Shops highlights strengths of top composites facilities

CW learned from some of this year’s designated Top Shops about what makes facilities stand out, from diverse capabilities to Industry 4.0 and sustainability.

WatchSAM|XL develops closed-loop manufacturing for composites

Collaborative R&D center at TU Delft develops sensor- and robot-based automation for Composites 4.0 manufacturing, including STUNNING project for welded assembly of a thermoplastic composite fuselage demonstrator.

WatchMikrosam celebrates commissioning of world's largest production line for CNG and hydrogen tanks

Turnkey project integrates four filament winding machines, two large ovens and multiple robotic lines and buffering stations to produce 60,000 tanks per year.

Watch