Videos

Cabin Management Systems leverages Markforged carbon fiber 3D printers for FAA-compliant end-use parts

Cabin Management Solutions (CMS) incorporates the Markforged X7 printer and Onyx FR material for high-quality, rapid parts production for cabin management maintenance, upgrades and replacements for luxury aircraft.

WatchHanwha Solutions acquires Cimarron Composites, aims to be global leader in high-pressure tanks by 2030

Hanwha Cimarron LLC will build new $130 million production facility in Alabama to produce large-scale tanks for hydrogen transport, filling stations and support expansion into tanks for UAM, drones, launch vehicle rockets, defense, rail, cargo ships and more.

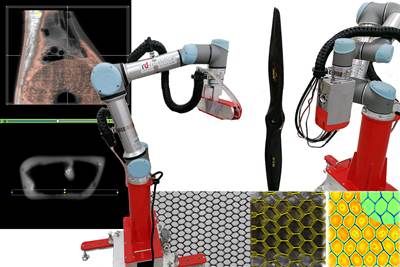

WatchRobotic computed tomography – removing NDT barriers for composites

Radalytica uses collaborative robots, ultra-sensitive X-ray photon detectors and the ability to combine CT with ultrasound, surface profiling and other inspection methods to optimize composites part quality, production and reduce cost.

WatchComposites opportunities in a growing infrastructure market: CW Trending episode 2

This episode of CW Trending, sponsored by Composites One, takes a look at the opportunities for expanded use of composites in infrastructure applications.

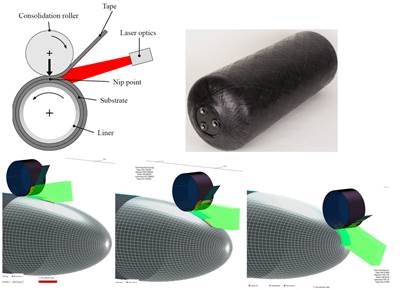

WatchOTOMcomposite develops software for Composites 4.0 production using laser-assisted tape placement and winding

Optical thermal optimization model (OTOM) software enables inline monitoring and control for improved part quality and reduced production time and cost of in-situ consolidated thermoplastic composites and Type IV pressure vessels.

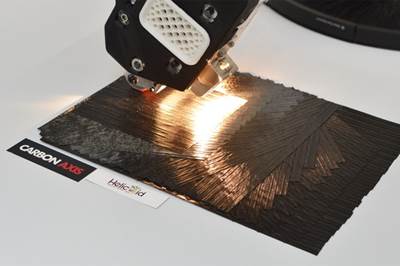

WatchCalTestBed voucher advances R&D efforts for Helicoid Industries leading edge protection technology

In partnership with the University of California, Irvine and New Energy Nexus’ CalTestBed Initiative, Helicoid Industries is to test and de-risk Helicoid leading edge protection technology solution for lighter, highly efficient and durable composite wind blades.

WatchCRP Technology celebrates 25 years of 3D printing advancements

Founded in the late 1990s, CRP Technology continues to strive for bold innovation and strong contributions through the evolution of its Windform materials and high-performance electric vehicles.

WatchCW Trending: composites opportunities in a growing infrastructure market

Learn from Editor-In-Chief, Jeff Sloan and guests Joe Fox and Gareth Williams about the trends they are seeing in the democratization of composites.

WatchLeveraging large-format AM fuels aerospace flexibility

Ascent Aerospace is known for producing high-quality metallic molds and tools for large aerostructures. Investment in large-format AM has expanded the company’s capabilities.

WatchNTU Singapore, Arkema manufacture carbon fiber helmets using Elium resin

Carbon fiber reinforcement increases stiffness, toughness of the helmet’s outer shell and allows it to absorb more impact energy over a longer period.

WatchEHang commences Yunfu production facility operations

The retrofitted autonomous aerial vehicle (AAV) production facility, which includes a carbon fiber composite materials processing area, is to scale up company production capabilities and cover approximately 24,000 square meters.

WatchDLR ZLP demonstrates new method for thermoplastic composite hydrogen fuel tank

AFP uses xenon lamp heating and inline QA to achieve innovative design which also uses ultrasonic welding.

Watch