Videos

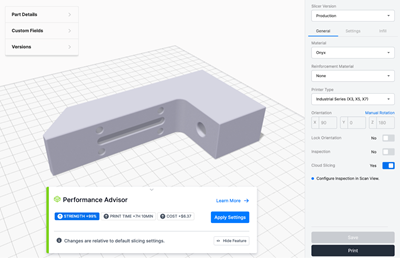

Markforged optimizes 3D-printed part performance with Performance Advisor

The physics-based analysis method is use case independent, automatically providing print settings that will give users options to increase part strength while optimizing for cost and print time.

WatchBio-based, fire-resistant composites become mainstream

Projects use Duplicor prepreg panels with highest Euroclass B fire performance without fire retardants for reduced weight, CO2 footprint in sustainable yet affordable roofs, high-rise façades and modular housing.

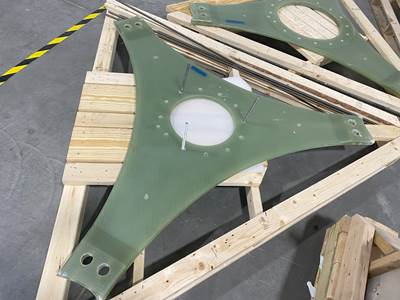

WatchRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

WatchJEC World 2024 preview

The world’s largest composites industry trade event returns to Paris, France, March 5-7, 2024, featuring exhibits, awards, conference programming and more.

WatchComposites end markets: Infrastructure and construction (2024)

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

WatchFlax fiber composite innovations, circularity services

JEC World 2024: Flax fiber producer Groupe Depestele and sustainable composites company Greenboats demonstrate flax fiber materials, demonstrators and product offer Circular Structures.

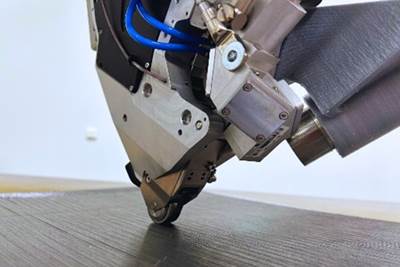

WatchCoriolis introduces hybrid CPico AFP machine

This compact cell brings together 3D printing, AFP and milling aided by a comprehensive software program, further simplifying the manufacture of complex thermoplastic composite aerostructures in the future.

WatchNCC commissions Cygnet Texkimp filament winder for hydrogen development

Multifunctional four-axis winding system offering fiber flexibility will underpin the NCC’s work in testing and manufacturing pressure vessels leading to commercial production.

WatchComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

WatchFIBRE4YARDS incorporates next-gen composites technologies to redefine shipbuilding

At the project’s completion, consortium members have unveiled final results and a 1:1 scale demonstrator, highlighting the opportunities for more collaborative, digitized, automated, efficient and environmentally friendly shipyards.

WatchComposites end markets: Sports and recreation (2024)

Light weight and high performance continue to make composites popular in the elite sporting good market. Sustainability in both materials and recycling solutions are a key innovation area.

WatchMulti-material, self-sensing, 3D-printed scoliosis braces

Startup Fited and Brightlands Materials Center have developed a lighter weight, thinner CFRP corrective brace, including pressure sensors made from continuous carbon fibers.

Watch