Digital mold solution improves energy savings, reduces cycle times

CAMX 2024: SensXPERT showcases the Digital Mold, integrating material characterization sensors directly into plastics and composites manufacturing processes for improved product quality and scrap reduction.

Share

SensXPERT, operating within Netzsch Process Intelligence GmbH (Selb, Germany), is showcasing products and technologies for the optimization of plastics and composites manufacturing through enhanced real-time visibility and control. By integrating advanced sensor technologies into production processes, the company aims to enable manufacturers to optimize operations, reduce waste and enhance product quality.

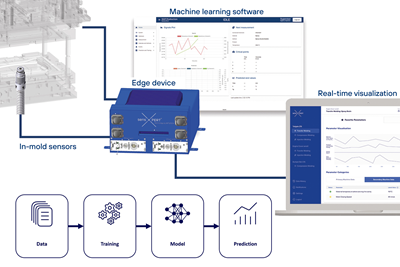

SensXPERT is particularly highlighting the Digital Mold. This solution integrates state-of-the-art material characterization sensors directly into plastics and composites manufacturing processes, providing continuous, real-time data on crucial material behavior during the curing process (read “Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics”).

The sensors are strategically embedded within molds, ensuring consistent and direct contact with the material throughout production. This setup is designed for precise monitoring of key properties such as degree of cure, crystallization, glass transition temperature and flow behavior. By employing dielectric analysis (DEA), the sensors analyze how molecules within the material respond to an electrical field, offering insights into material behavior.

The real-time data collected also enables manufacturers to make immediate adjustments to processing conditions. This capability is said to be pivotal in detecting and correcting deviations as they occur, optimizing production efficiency and ensuring every part meets stringent quality standards. From adjusting temperature settings to dynamically controlling cycle times, the sensXPERT Digital Mold provides a responsive feedback loop that can minimize waste and maximize yield.

Additional benefits delivered include:

- Up to 50% scrap reduction: By optimizing process parameters in real time, manufacturers can reduce material waste and improve production efficiency.

- Improved product quality: Consistent monitoring and control of material behaviors ensure each part meets or exceeds performance expectations.

- Up to 30% cycle time reduction and 23% in energy savings.

The Digital Mold is designed to seamlessly integrate with existing manufacturing setups, including third-party sensors and machine tool data. This holistic approach to data collection is said to provide comprehensive insights into the entire manufacturing process, which ultimately achieves continuous improvement and strategic decision-making.

Related Content

-

Digitized material shipment process improves MRAS aerostructures operations

Digital Passport technology by Plataine shortens receiving process to minutes, enhances quality and supply chain collaboration.

-

Large-scale additive system prints industrial molds for composites

CAMX 2023: The Massivit 10000-G, with gel dispensed printing offers an ultra-fast, sustainable and cost-effective way to digitize isotropic mold production for high-quality and more reliable composite parts.

-

Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

Related Content

Digitized material shipment process improves MRAS aerostructures operations

Digital Passport technology by Plataine shortens receiving process to minutes, enhances quality and supply chain collaboration.

Read MoreLarge-scale additive system prints industrial molds for composites

CAMX 2023: The Massivit 10000-G, with gel dispensed printing offers an ultra-fast, sustainable and cost-effective way to digitize isotropic mold production for high-quality and more reliable composite parts.

Read MoreNext-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

Read MoreNew AMRC facility, Boeing program boosts aerocomposites innovation

An £80 million investment contributes to a novel R&D facility in South Yorkshire, U.K., with Boeing as its first major research partner, to support and de-risk new composites and digital technologies and processes for the production of future aerospace components.

Read MoreRead Next

SensXPERT wins Best of Industry Award for Digital Mold technology

Providing real-time insights into manufacturing processes, the company’s measurement and testing technology was nominated as an innovative and breakthrough solution for industry.

Read MoreNext-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More