“We returned ... with the conviction that sailing flight was not the exclusive prerogative of birds.” — Otto Lilienthal, 1874.

Those words, written by a hang gliding pioneer, speak of a rich history of design development, one that continues today to attract enthusiasts drawn to soaring like a bird — without the noise of an engine. Switzerland is particularly well known for offering ideal hang gliding conditions — that is, tall mountains with steep slopes that serve as launch sites for pilots strapped into their gliders, as Helmut Wehren can attest. Wehren heads up a project group, dubbed “Wehren Emcom xxtherm2,” aimed at manufacturing the high-performance rigid hang glider of the same name in Jegenstorf, Switzerland: “The project was initially just for fun, among a group of friends.” He notes, “But we realized our initial ideas and first aircraft didn’t consider manufacturability, so six years ago we started on a second aircraft design, the xxtherm2.”

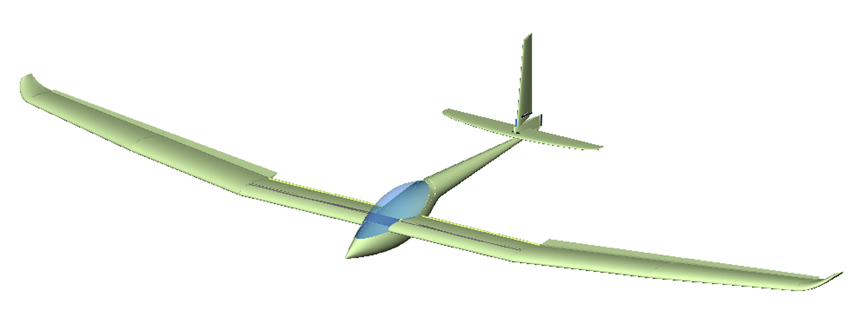

The Fédération Aéronautique Internationale (FAI, Lausanne, Switzerland) defines three classes of competition hang gliders: flexible wing hang gliders, where the pilot is suspended, typically in a sling or bag, and controls a delta-shaped wing with simple weight shifts; rigid wing hang gliders that require spoilers and ailerons for flight control; and Class 2, Subclass O-2 rigid wing hang gliders with flight controls and a fairing or small cockpit. Pilots in all three types have set impressive soaring and distance records over the years. The all-carbon composite xxtherm2, intended for such long-distance competitions, falls into the third category.

Building a better hang glider

Says Wehren: “In 2006 we had only the intention to build a foot-launchable glider for our own flying, without any plan to produce it. The xxtherm1 was designed the classic way: first some crazy ideas, then more detailed concepts, studies and design calculations. And at the end, we asked the most important question: How is this supposed to be manufactured?”

In 2012, the group started again with a clean sheet, using design tools that included a lot of paper and pencil, in addition to ViaCAD software by punch!CAD (Cedar Rapids, IA, US) for 2D and 3D modeling and drafting. Aerodynamic analysis and design of airfoils and wings operating at low Reynolds number was carried out using open-source web software XFLR5. Also important were spreadsheets used for calculation of structures, loads, composite characteristics, weight and balance, bill of materials, etc.

Clearly, composites were the only material option for the small craft. They would deliver the lightest possible weight, which would enable foot launching while delivering tailorable flight characteristics and very high glide (lift:drag) ratio. The xxtherm2’s glide ratio is greater than 35, thanks to wing refinements and the use of a laminar airfoil, compared to the original xxtherm1 iteration.

The design also had to balance the demands of aerodynamics with portability, given that one must be able to disassemble and pack a hang glider in a container for car transport to competitions. The group wanted the aircraft parts to fit within a 4.8m/16-ft-long container, which could be placed on a small trailer and weigh, together with the container, less than 75 kg.

The wings, each 4.8m long, are built in three parts, to enable breakdown and transport, yet deliver performance while facilitating foot-launch. Wehren points out that an aircraft’s planform should be designed with the center of gravity and the aerodynamic center of the aircraft in the same location: “In a light, foot-launch aircraft like the xxtherm2, the main wing spar would cross the fuselage at the place where the pilot sits. So, I moved the wing forward in front of the pilot. And to compensate, the outer wings are swept back to move the aerodynamic center back to the pilot. This way, the aircraft is balanced when the pilot is lifting it and also balanced in flight, with no aerodynamic trim control needed during foot launch.”

To determine where the wing segments detach/assemble, Wehren explains that it depended on the bending moment in the spar: “The greatest bending moment in a spar is in the center of the wingspan. By designing the outer wings’ detach point more than 2m away from the fuselage, the bending moment is reduced to roughly 40% of the maximum, making the coupling of the wings much easier and lighter in weight.” He adds that the spar of the inner wing has a pocket at the end, into which the stub spar of the outer wing is inserted. A spring-loaded bolt secures the outer wing, while the inner main wing is fixed on the fuselage with bolts in bushings.

The xxtherm2 craft’s wings, tail and flaps are made with carbon fiber, a 160-g/m2 (4.7-oz/yd2) spread carbon twill (Style 67442), over Nomex honeycomb core, Type CS 3.2-29, both from the supplier for all the project’s materials: distributor Swiss-Composite (Fraubrunnen, Switzerland). Wehren notes that the honeycomb sandwich had to be overdesigned, beyond the stiffness needed for air loads: “There exist some challenges for the aircraft panels caused by spectators and other curious people, who look with the fingers instead of the eyes. This leads to some higher strength demand for sandwich panels, in the realm of 5 kg per thumb,” he quips.

The craft’s cockpit was designed as a hybrid shell of carbon fiber and ultra high molecular weight polyethylene (UHMWPE) (using Dyneema UHMWPE fiber from DSM Dyneema, Geleen, The Netherlands), with a stiff carbon frame and thermoformed side skins, cored with a polyvinyl chloride (PVC) foam (Airex C 70.75, from Airex AG, Sins, Switzerland).

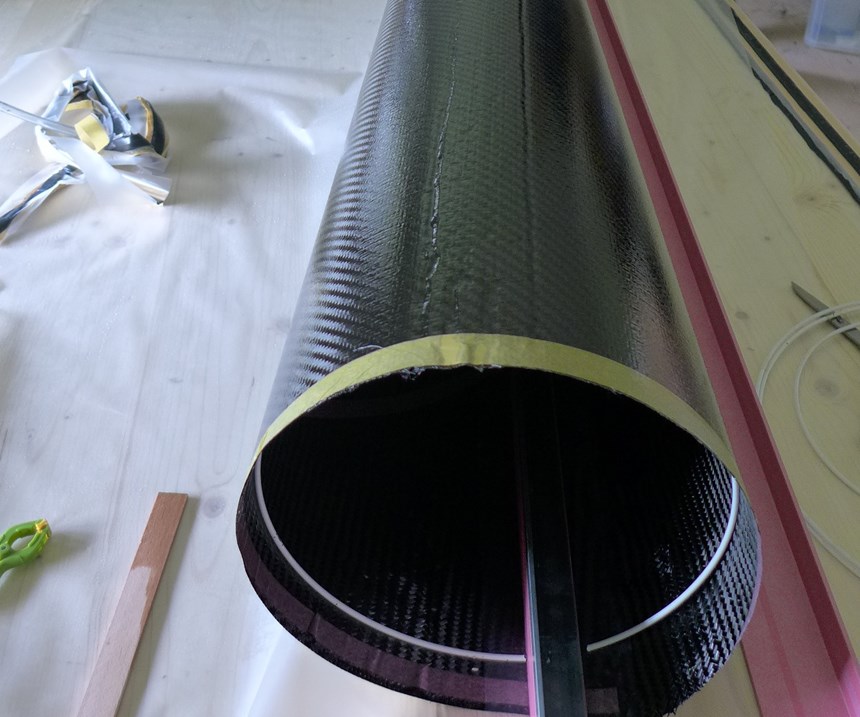

The tail is a conical monolithic carbon fiber tube, constructed using the same materials used for the wings and flaps, and with internal composite stiffeners and frames and protective outer ply of 105 g/m2 glass fiber twill in a resin infusion process.

A focus on manufacturability

To fabricate the xxtherm2’s parts, Wehren, his son Hannes and the rest of the group developed a low-cost, efficient manufacturing process technology they call BFM, for bifunctional flexible molds.

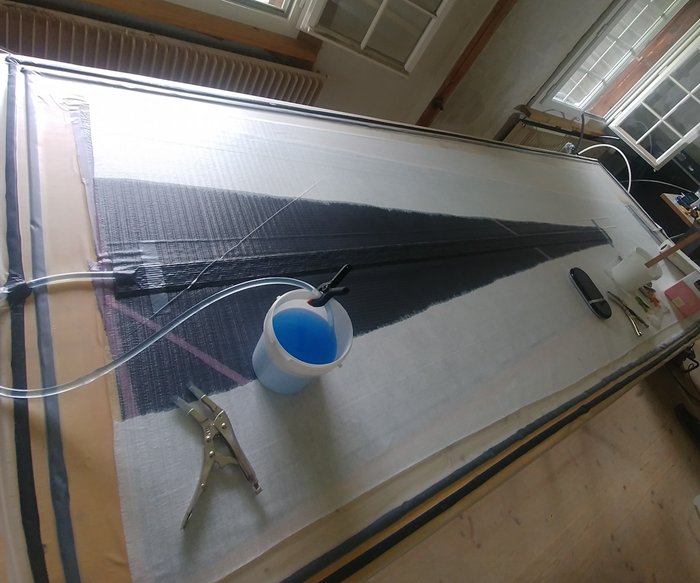

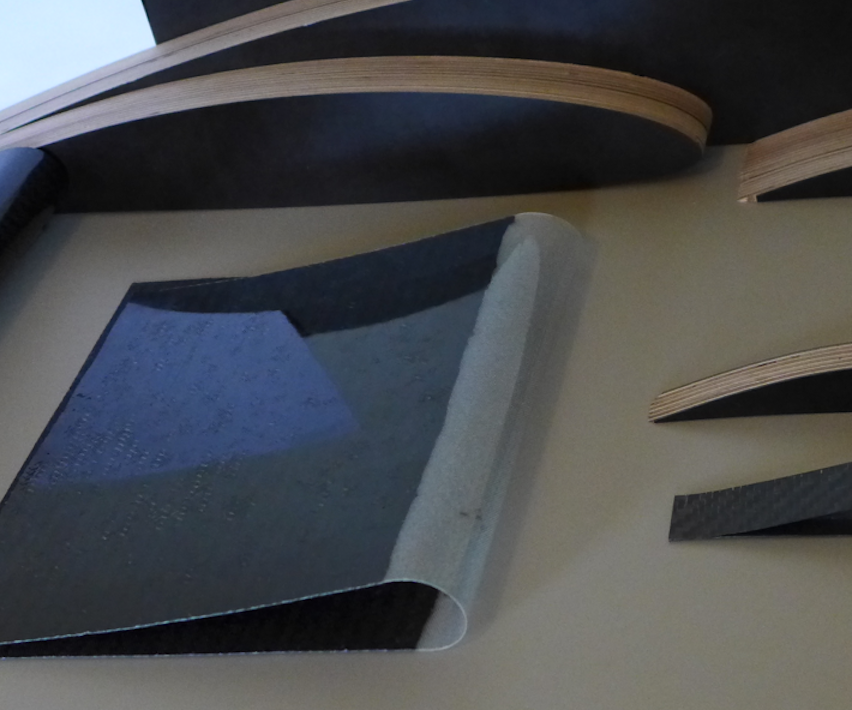

All parts of the airframe are produced with this technology, via resin infusion, using Hexion (Columbus, OH, US) L-285 epoxy resin. Instead of typical solid female molds or male mandrels, the process uses thin composite laminate sheets that function in a dual capacity: Flexible molds that become part of the component. Says Wehren, “It can be described as a construction equipment being itself part of an assembly.” The composite laminates or sheets can be carbon, glass or aramid, in prepreg form or dry reinforcements.

The process takes advantage of the specific in-plane stiffness of a bent fiber-reinforced composite sheet. It can produce components in solid laminate or cored sandwich form. The end result can be anything from simple panels, straight or tapered tubes and cylinders to aircraft wings, ailerons, flaps, rudders and fuselage tubes. The process is capable of much beyond aerospace, says Wehren. Automotive bodywork or coachwork, railway coachwork, boat decks, masts, rudders, poles, beams, furniture, trays and the inner reinforcing structures of any component can be fabricated. Parts can be built in negative (female) or positive (male) form.

Wehren describes how it works. A thin carbon sheet forms the mold for an aircraft wing panel and then becomes the outer layer of the wing after cure of the additional laminate plies: “There are only two resin infusions on a flat surface, the first one to produce the flexible mold sheet, the second one to complete the part laminate.” The thin composite laminate that will double as the mold is made on a flat or otherwise formed surface and cured until hard. This gives the molder a flexible but, if bent, stiff composite sheet. “The flat working surface defines the structure and quality of the laminate lower, or outer, side.”

One or more plies of reinforcing fibers (glass, carbon, aramid, etc.), or one or more layers combined with foam or honeycomb cores or other materials, are added on top of this sheet and impregnated with resin. This still flexible but lengthwise-stiff ensemble, the lower side being the cured flexible shell and the upper side consisting of the additional wet layers, is then placed over appropriately positioned templates, frames or ribs, giving the assembly its specific designated shape, at which point the flexible lower shell takes final part shape (after having served as the mold for the wet layers on the upper side). At cure, the mold thus becomes a member of the part (e.g., the wing surface) and, together with all the added layers, forms the complete wing panel. For example, the bi-functional flexible mold process allows the molder to produce wingskins as seamless shells from trailing edge to trailing edge, without a splice at the airfoil nose. The trailing edges are joined, wet in wet, and co-cured. This process can be used at room temperature or at elevated temperature. “It’s an ideal method for resin infusion processes. A panel is produced with two single infusions on a flat plate and there is no need for work in a 3D mold,” Wehren sums up.

Concludes Wehren: “The xxtherm2 was designed inversely, beginning with simplicity, manufacturability, reliability, safety, quality. This led to structures, ways of construction, choice of materials, jigs and tools, ways of working, balance of external labor and personal contribution, and a balance of material vs. labor costs. And we allowed ourselves enough time to walk the road without detours.” The actual xxtherm2 is in a prototype stage, and first test flights will commence before the end of 2018.

Related Content

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreCompPair adds swift prepreg line to HealTech Standard product family

The HealTech Standard product family from CompPair has been expanded with the addition of CS02, a swift prepreg line.

Read MoreVIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More