Aircraft Repair Can And Should Be Automated

Consultant Fred Perkins (Federal Engineering Associates LLC, McLean, Va.) is currently involved in quality control and mission assurance for defense programs as well as a Phase I SBIR program for the U.S. Air Force, applying stochastic design analysis to finite element modeling of composite aircraft part repairs.

Day by day, the world's aircraft inventory gets older. Those first-generation aircraft — the first to use "advanced composite aircraft technology" — are now being retired and sometimes reduced to scrap. Any way you slice it, composite aircraft parts are getting older, accumulating the effects of FOD (foreign object damage), withstanding the ravages of environmental exposure, and bearing operating loads not always as designed. Repair stations are full of composite parts, and a wide range of military and civil aircraft are on the ground, in need of repair or part replacement before they can return to service. And, like all of us who have accumulated a few years, no two planes or parts are the same, since each has its own wear history.

Until now, composite aircraft part repairs have been performed by skilled mechanics using manual processes. In February, however, I attended a technology forum that signals welcome and long overdue change. Hosted by American GFM (AGFM) at its facility in Chesapeake, Va., the purpose of the gathering was to discuss techniques and a systems approach for implementing the Aging Aircraft Repair Initiative. Automation of repair processes is a tall order, but as discussed at the meeting, advancing technology now enables automation of challenging composite aircraft part repairs in dedicated workcells, despite the inevitable variability between in-service parts and their individual histories. Automation promises improved repairs at lower cost, reduced scrap, improved throughput and faster return of aircraft to service. With individual composite aircraft part costs running into six figures, and daily lost revenue for aircraft on the ground running into seven figures, even a substantial investment in repair automation would quickly pay for itself.

The essential elements of effective composite aircraft part repair automation are:

- Automatic, high-resolution metrology (measurement) to determine the actual 3-D shape of the in-service part and its location in the workcell.

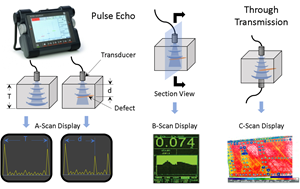

- Automatic nondestructive testing (NDT) to determine the exact location and extent of composite part damage.

- Precise, clean removal of damaged composite material and preparation for the repair.

- Accurate cutting and placement of composite stock to effect the repair.

- Predictable curing processes to assure strong repairs and control part deformations induced by the repair curing process.

Technology solutions for each aspect of these requirements were demonstrated at the AGFM workshop. Accordion fringe interferometry provided automated high-resolution metrology without the traditional requirement of superimposed photogrammetry, thus accelerating throughput and improving accuracy. Laser shearography was seen to be a fast and accurate method for NDT, mapping defects onto the 3-D shape of the part. Ultrasonic cutting tools with high-accuracy 3-D control and precise cutters use these data to remove damaged material and accurately cut the stock textile and honeycomb materials needed for the repair. Laser assembly guidance systems integrated into the ultrasonic cutter ensure that the composite textiles are kitted properly, and also map the location of the kitted composite textiles onto the repair's surface, assuring a defect-free repair. Proprietary technologies tack the uncured composites into place prior to cure. These technologies, packaged as integrated end-effectors, swapped positions as they were needed in an intricate mechanical ballet. And, though still at an early stage, Federal Engineering Associates (McLean, Va.) is developing integrated finite element modeling software designed to automatically evaluate the repair, assuring adequate strength and controlling unplanned deformations of the repair from a variety of sources.

Support from the U.S. Air Force will transform this automated workcell vision into reality, integrating the constituent technologies at a logistics center, where they will be applied to improving composite aircraft part repair, making the advanced technologies introduced by the Aging Aircraft Repair Initiative the new standard for aircraft repair.

We old dogs are learning some new tricks. The future is coming quicker than we thought, and just in time for the next generation of advanced composite aircraft technology.

Editor's note: See the related article on automated repair (p. 30) and our featured NDT update on p. 56.

Related Content

Xnovo Technology, Exciscope introduce X-ray tensor tomography technique

Through a strategic partnership, the companies introduce the FiberScanner3D module, dedicated to bringing more rapid, reliable and robust fiber structure characterization methods to lab settings.

Read MoreNDT inspection services, automated systems serve aerospace needs

CAMX 2023: Arcadia Aerospace Industries demonstrates its commitment to navigating the rapidly changing aerospace manufacturing landscape with robotic-based machines and motion control systems, certified facilities for NDT services and conducted training and recruitment.

Read MoreInnovation in ultrasonic inspection and nondestructive testing

With increasingly complex structural components working their way into aerospace programs, the need for versatility in inspection and testing capabilities is growing.

Read MoreNondestructive inspection methods available to composites manufacturers

An overview of composite laminate inspection techniques ranging from manual testing methods to more advanced, noncontact options.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More