Architectural composites: Rising to new challenges

In North America, Europe, the Middle East and Down Under, architects and engineers are finding composites are a good fit in groundbreaking applications.

Composites have been used for more than 50 years in a variety of residential and commercial building applications but have not acquired the mainstream status of wood products, aluminum, steel, stone and reinforced concrete. Barriers to composites have varied from the actual — their cost and building codes overdue for revision — to the perceptual — the builder’s preference for construction materials familiar to contractors and their crews. But the construction industry’s initially cool reception to composites is thawing. Recent developments, as the applications to follow demonstrate, are an indication that reluctance and perceived restrictions are fading. Construction industry professionals are warming to the possibilities of composites, freeing architectural firms to employ their superior properties creatively, to great functional and aesthetic advantage.

Rising to the challenge

Build it and they will come. So goes the viral quote from the 1989 American fantasy film, Field of Dreams, whose protagonist builds a small baseball stadium that attracts legendary but long-dead ball players. But as any U.S. architect, engineer or building contractor will tell you, you can’t build your dream if codes won’t permit it.

To be sure, the plethora of federal, state and local building codes have never explicitly prevented the use of composites. Although the nominally higher price point of composites played a part in their lack of use, the biggest impediment to large-scale adoption of composites, especially in the lucrative commercial market, was the fact that nowhere in the International Code Council’s (ICC, Washington, D.C.) International Building Code (IBC), the template for most of the local U.S. codes, were fiber-reinforced polymer (FRP) materials defined as a class of interior and exterior building materials for use in specific applications. “The IBC is a prescriptive document, which provides a recipe by which to build a building, so it’s important that your material is actually defined in the Code,” explains Nicholas Dembsey, professor of Fire Protection Engineering, Worcester Polytechnic Institute (Worcester, Mass.). “If it’s not, it nominally does not exist.” Before FRP was defined in the IBC, he points out, it could be used in tall commercial buildings, but only on a special case, “alternative methods and materials” basis. This meant that an architect or engineering firm would have to appeal to a local “Authority Having Jurisdiction,” who, more than likely, would have required stringent fire and smoke testing, especially if the FRP was to be used in large amounts above the fourth floor. The net effect of this “ad-hoc approach” for approval of FRP was to constrain composites to small-volume decorative and functional elements, such as cornices, columns, window lineals and skylights, effectively inhibiting any widescale use in commercial construction.

This oversight was finally corrected in 2009. An American Composites Manufacturing Assn. (Arlington, Va.) task force chaired by Prof. Dembsey, with assistance from Jesse Beitel, FPE, PE, a senior scientist and principal at code consulting firm Hughes Associates (Baltimore, Md.), drafted an amendment to the IBC that included a new subsection on composite building materials. The ICC approved it, and it became Chapter 26, “Plastic,” Subsection 12, “Fiber-Reinforced Polymers,” which explicitly permits the use of FRP in both interior finish applications, such as walls and ceilings, and in nonstructural exterior assemblies, including curtain walls, cladding and rain screens.

The benefit of having FRP defined and regulated in the IBC is that the material now can be considered as part of the prescriptive, that is, the normal, design process, Dembsey notes. As part of that prescriptive process, materials and assemblies made from FRP — like other traditional materials — can be used above the fourth floor as long as they meet the acceptance criteria of NFPA 285, the National Fire Protection Assn.’s (Quincy, Mass.) stringent performance-based fire test for evaluating the fire propagation characteristics of exterior, non-load-bearing wall assemblies. That clarity in the IBC, as the following case study demonstrates, should open doors.

Artful introduction

The Code change already has yielded one composites coup: A 235,000-ft2 (21,832m2) expansion to the San Francisco Museum of Modern Art (SFMOMA) includes a curved, 35,000-ft2 (3,252m2), 12-story rain-screen façade made of FRP panels — to date, the largest architectural application of composites in the U.S., and the first building in the U.S. designed and built with an primarily FRP exterior section taller than 40 ft/12.2m (see “The building envelope: Betting on the big time," under "Editor's Picks”).

The building’s primary architect, Snohetta (Oslo, Norway), wanted to create a signature rippled façade for the SFMOMA expansion. Based on the firm’s experience integrating FRP into buildings outside the U.S., architects working on the project knew that lightweight FRP would be an ideal solution. However, Snohetta had accrued that history in locales where fire-codes are less stringent. Although the IBC 26.12 subsection had made the use of large amounts of FRP in a tall U.S. building possible, those materials still had to meet two other criteria: If the material could earn an IBC Class A fire-performance rating, as determined by ASTM E 85 (a test that determines the surface flame spread and smoke characteristics of building materials), it could be used in interior applications in any quantity, and for as much as 100 percent of a nonstructural exterior, if the building is no taller than 40 ft. For use on buildings taller than that however, the composite also would have to meet the more strict NFPA 285.

At a meeting with Snohetta about a different aspect of the project, Kreysler & Associates Inc. (American Canyon, Calif.) president Bill Kreysler inquired about the exterior façade and asked if Snohetta would entertain an FRP panel system for the project, assuming it were able to pass the NFPA 285 test. Drawing on in-house expertise, Kreysler partnered with materials suppliers to develop and test a proprietary FRP processing system that could produce test-capable panels. The material, however, was only one piece of the testing puzzle’s solution. “The 285 is not simply a material test, it’s an ‘assembly’ test,” Kreysler explains, “so even if you made the panels using exactly the materials we used, if it’s not put together using the proper assembly of joints, proper spacing behind the panel, etc., it might not pass the test.” Kreysler’s assembly did pass — at a cost of about $100,000 at a certified testing facility — and Kreysler was subsequently selected by the architect to supply the façade panels.

That was two years ago. Since then, Kreysler & Associates has produced about 700 panels for the project, which were, as CT went to press, in the assembly process on the expansion’s east elevation. The façade is scheduled for completion in early 2016.

Each panel is unique, but a “typical” panel is approximately 23 ft long by 5 ft wide by 0.25 inch thick (7.0m by 1.5m by 6.35 mm). The panels feature a flame- and smoke-retardant polyester/glass laminate manufactured via an open-mold, “wet-preg” process: Woven E-glass fabric is impregnated with polyester supplied by Ashland Performance Materials (Dublin, Ohio), to which a proprietary blend of additives and fillers is added just before fabric impregnation and insertion into molds CNC-machined from EPS foam.

The polyester cures at room temperature in two hours. The part is then postcured at 190°F/88°C by pumping heated air under an insulated cover, which is placed over the mold and designed to draw off the residual unreacted styrene typically emitted from room-temperature-cured polyester laminates. Kreysler maintains that a wet, open-molding process enables his staff to maintain highly accurate fiber-volume ratios, a critical quality-control parameter that ensures a system will earn required fire-performance ratings. While he declines to give a precise figure, Kreylser acknowledges that the fiber volume of the finished laminate “is very high.” Prior to part layup, a polymer/concrete face-coat, not unlike a conventional gel-coat, is first down in the mold. After layup, cure and demolding, the panel’s face-coat layer is sandblasted to impart a stone-like texture to the panel surface. The polymer/concrete layer enhances the panel’s cosmetics and its UV- and fire-resistance.

Overall, the FRP façade not only gave the architect the freedom to incorporate a striking, nonflat design into the building, but also afforded engineers the opportunity to eliminate about 1 million lb (453.6 metric tonnes) of structural steel, which would have been necessary to support the panels if they had been constructed entirely of glass-reinforced concrete. Instead, Kreysler’s FRP panels can be attached to a lightweight unitized aluminum panel-framing system manufactured by Enclos (Eagan, Minn.). Similar systems are typically used to enclose a high-rise building but are flat or, at best, can be curved in only one direction. With the FRP “rain screen” mounted to the surface of the unitized panels, the building façade can take on a far more complex form while retaining the conventional waterproofing systems used in unitized panels.

International markets expand

Commercial applications of architectural composites on the scale of the SFMOMA façade are historically more common outside the U.S. There, they are expanding and challenging manufacturers and suppliers to come up with fresh design solutions that will meet all engineering, safety and aesthetic requirements.

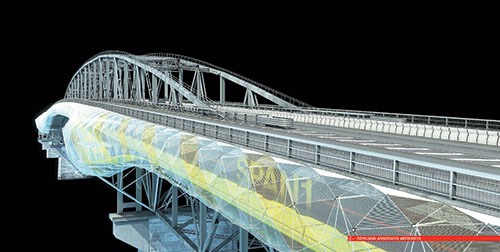

One such project is SkyPath, an enclosed walking/cycling path soon to be attached to the underside of the Auckland Harbour Bridge in Auckland, New Zealand. Construction begins this year with completion expected by the end of 2016. The 1.1-km/0.68-mile long tubular structure will be constructed, in part, of modular composite sandwich panel decking, designed and manufactured by Core Builders Composites (CBC, Warmouth, New Zealand).

Each panel is 13.7m long by 4m wide (45 ft by 13.1 ft), comprising Gurit GPET 100 FR foam core (40 percent by weight) between faceskins of quadraxial E-glass fabric (24 percent) and unidirectional carbon fiber (2 percent) in an epoxy matrix (30 percent). The project is expected to require more than 4000m2 (43,055 ft2) of panels and some 250 10m/32.8-ft long E-glass/carbon fiber-reinforced ribs, which attach SkyPath to the existing motor-traffic bridge deck overhead and provide primary structural support for the composite walkway below.

Also in New Zealand, a composite “folded-plate” roof is the architectural focal point of the new, commemorative Marsden Cross Interpretive Centre, which marks the location of the country’s first missionary settlement. The 148m2/1,590-ft2 roof’s nominal thickness is 45 mm/1.77 inches, with spans of up to 7m/23 ft between support posts. According to Tony Stanton, engineering manager at Gurit UK (Asia Pacific) Ltd. (Belrose, New South Wales, Australia), the varying heights and angles in the roof design would subject the finished structure to a host of variable localized loads. The engineering team, comprising representatives from Cheshire Architects (Auckland, New Zealand), Core Builders Composites and Gurit, optimized the laminate for the roof’s sandwich structure using Hyperworks FEA software, supplied by Altair Engineering Inc. (Troy, Mich.). The final design consisted of a Gurit G-PET 90 foam core between faceskins of E-glass multiaxials, with optimized carbon reinforcements in critical-load areas, vacuum infused with epoxy resin.

CBC manufactured the panels on a flat infusion table, then CNC machined individual shapes with a precise edge miter — a requirement in order to seamlessly join multiple panels at single nodes repeatedly across the roof structure. The panels were pre-assembled in two large sections on a jig, then transported to the construction site where they were joined into the full roof assembly.

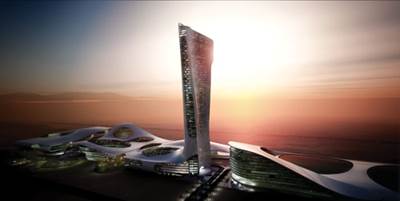

In Saudi Arabia, FRP roofs for four railway terminal stations that will serve that country’s 444-km/276-mile Haramain High Speed Rail system are under construction. Premier Composites Technologies (PCT, Dubai, U.A.E.) manufactured the panels for the Medinah station (see “Premier Composite Technologies wins rail station structures contract,” under "Editor's Picks") using Gurit’s fire-resistant FRP foam core, GPET 75FR, and Gurit’s epoxy laminating system, AMPREG 21FR, with a glass fiber volume of approximately 35 percent. Another fabricator, Saudi Oger Ltd. (Riyadh, Saudi Arabia), employed the same materials system to manufacture the roofing panels for the Jeddah station. The roof for the Medinah station was completed this year. The roof at the Jeddah station is still in progress.

Windows worth framing

Deceuninck NV (Bruggesteenweg, Belgium), a designer, manufacturer and supplier of vinyl door and window components, introduced its Innergy line of pultruded glass-reinforced polyurethane window reinforcements at the 2012 GlassBuild Show in Atlanta, Ga., where the product won the show’s Crystal Achievement award as the Most Innovative. The reinforcements, which provide structural support within the window frame and sash, are made from a grade of Baydur polyurethane, supplied by Bayer MaterialScience (Pittsburgh, Pa.), and are 80 percent glass by weight, providing a flexural modulus of 7.5 million psi — a value nearly on par with aluminum’s (10 million psi). The polyurethane inserts also offer a 700 percent boost in thermal performance over aluminum inserts.

Deceuninck designed the Innergy line as drop-in replacements for aluminum reinforcements. This means that window manufacturers do not have to re-qualify current window lines when they switch to Innergy reinforcements (see more in "Pultruded window: Glass/polyurethane prototype wins award” under "Editor's Picks,"at top right).

The company also has launched its trademarked eos (Energy Optimized System) vinyl window system, which incorporates Innergy glass-reinforced polyurethane reinforcements in a design intended to meet the energy-efficiency requirements of Energy Star 6.0, a program developed by the U.S. Environmental Protection Agency (EPA) to establish energy performance standards that suppliers and contractors must meet if they want Energy Star certification for a building product or finished home. The voluntary standards are scheduled to go into effect in phases over the next several years. A residential window meets the standard if it achieves a U-value rating of 0.27. U-value is the overall heat transfer coefficient — that is, it measures the rate of heat transfer (in watts) through 1m2 of a structure divided by the difference in measured temperatures across the structure.

According to Dave Jacobson, marketing director at Deceuninck North America (Monroe, Ohio), the initial applications of Innergy reinforcements were as alternate components that could be fitted into the frame members of existing window systems. The eos windows, however, have Innergy technology integrated into their designs upfront, which, in turn, enables optimization of lineal and insert-chamber energy efficiency. This has resulted in a window that meets the Energy Star standard of a 0.27 U-value in a double-pane format, and yields an even better 0.20 U-value when employed in triple-pane configuration.

Graham Architectural Products (York, Pa.) introduced its fully composite window system, tradenamed GThurm Windows, to the construction market in 2011. The windows feature frames, lineals and sashes made from pultruded profiles that comprise approximately 80 percent glass and 20 percent polyurethane. Initially, its sister company, Graham Engineering, manufactured the profiles. However, in 2013, the Graham division sold its pultrusion equipment to Deceuninck NV, which now manufactures the GThurm profiles. Graham Architectural Products still assembles the windows, and Jim Eisendeis, marketing director, reports the company is working on a number of new designs, which it plans to introduce over the coming calendar year.

The GThurm line is made with a proprietary surface-treatment technology, applied postmold, that permits adhesion of paint to the glass-rich composite surface. “The essential advantage of these windows is that the entire material system is a thermal break, whereas with other windows you have incorporate a thermal break as an add-on,” says Eisendeis. The company reports a U-value as low as 0.21 for its G6000 Series of casement windows, and a U-value as low as 0.15 for the G6000 Series fixed, architectural-grade windows.

In the wake of the IBC’s definition, de facto restrictions have lifted on FRP use in buildings. Architects and engineers are developing a greater appreciation for the aesthetic, cost and energy benefits afforded by incorporating composites in residential and commercial buildings. The only limitations for continued expansion of composites in architecture at present appear to be “unwritten” ones, which favor traditional materials because they have been used in the past. As designers and engineers become more familiar with composites, the natural benefits of the materials will come to the fore. When this happens, to paraphrase one industry observer, the demand for composites in architecture and construction could outstrip even the materials’ traditional markets of aerospace and marine.

Related Content

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreCompPair adds swift prepreg line to HealTech Standard product family

The HealTech Standard product family from CompPair has been expanded with the addition of CS02, a swift prepreg line.

Read MoreVIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreRead Next

Pultruded window: Glass/polyurethane prototype wins award

Deceuninck Group NV (Hooglede-Gits, Belgium), is at the forefront of composite window frame design and innovation, as evidenced by its recent award for a large, prototype window designed to open like a door.

Read MoreThe building envelope: Betting on the big time

Building code changes and growing architect familiarity feed more frequent composites use in large-scale commercial construction.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More