Auto industry explores engineering thermoplastic performance improvements

Polyamides, carbon fiber prominent at 2019 SPE AutoEPCON.

A number of companies introduced new products at the show. For example, JM Polymers added three more grades to its FiberX2 line of recycled, injection-moldable short carbon fiber-reinforced polyamide 6/6. Source | Katie Okonski/SPE

The Society of Plastics Engineers (SPE, Bethel, Conn., U.S.) met in Troy, Mich., U.S., on May 7 to hold its 14th Automotive Engineering Plastics Conference (AutoEPCON). The one-day event bridges the performance gap between SPE’s Detroit area TPO Automotive Engineered Polyolefins Conference (Auto TPO) and its Automotive Composites Conference & Exhibition (ACCE).

AutoEPCON’s 2019 technical program featured four keynotes plus 27 technical talks in three parallel sessions. During morning and afternoon breaks, 325 attendees visited 21 exhibits and networked, then attended an evening reception.

Interestingly, persistent themes at this year’s conference were polyamide (PA) resins and carbon fiber-reinforced thermoplastics (CFRTPs).

PA 6/6 shortages

Polyamides were a major focus, in part owing to a global shortage of PA 6/6, which, along with PA 6, is widely used in the automotive industry — both neat and reinforced, for interior, exterior, underhood and powertrain applications. Until supply bottlenecks clear, OEMs and suppliers are scrambling to find other options, such as alternative polymers or recycled PA 6/6, which doesn’t sacrifice performance. It was no surprise, therefore, to see many exhibitors touting PA 6/6 alternatives in their displays, as well as many speakers describing virgin and recycled options. In fact, in his keynote on “Nylon and Polycarbonate: How We Got Here and What Lies Ahead,” Brendan Dooley, global director-engineering polymers, IHS Markit (Houston, Texas, U.S.), discussed the cascade of unfortunate events that caused this situation.

“This segment has had more than its share of challenges,” explained Dooley. “First, a catastrophic 2015 fire at a new adiponitrile factory in China wiped out 18% of the global supply of monomer needed to produce PA 6/6. That plant has not been rebuilt. Furthermore, supplies have been affected by disruptions caused by excessively hot weather, excessively cold weather, hurricanes, utility failures, fires and labor actions. And later this year, an adiponitrile plant in France will shut down for maintenance and upgrades. While eventually the expansion will boost global adiponitrile production capacity, in the short term it will make supplies even tighter.” Dooley foresees PA 6/6 supplies starting to ease in 2020 and says they should be back to price parity with PA 6 by 2022.

Carbon fiber upgrades

Carbon fiber was another big topic, but for different reasons. Last year, only a couple of speakers mentioned — and only a few exhibitors highlighted — CFRTPs. This year, however, they were discussed in at least six different sessions, and in a keynote on “Engineering Plastics and Additive Manufacturing” by Kevin Quinn, director of additive design and manufacturing, General Motors Co. (Detroit, Mich., U.S.). Additionally, several companies introduced new carbon fiber-reinforced PA (CF/PA) materials at the show.

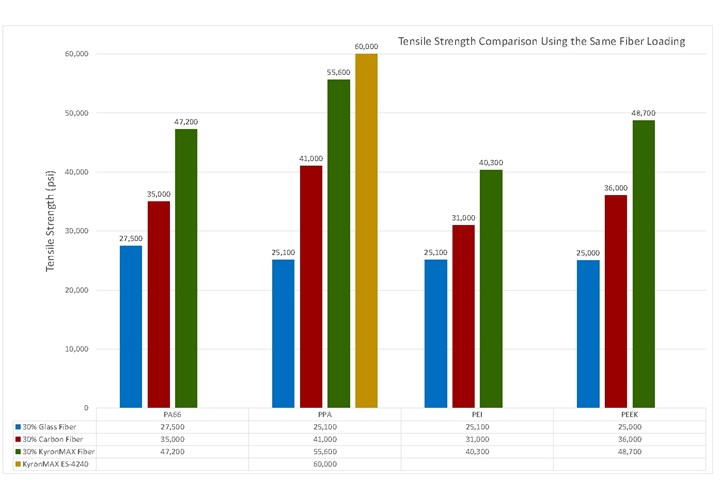

Mitsubishi Chemical Advanced Materials Inc. introduced its new 40 wt-% CF/PPA compound called KyronMax ES 4240 (gold bar in graph above) at the 14th SPE AutoEPCON. Source | Mitsubishi Chemical Advanced Materials Inc.

Among these were JM Polymers (Chicago, Ill., U.S.), which last year launched its FiberX2 line of recycled, injection-moldable grades of short CF/PA 6/6. The fiber is reclaimed from aerospace prepreg and the resin is recycled from sporting goods. The initial offering was two grades reinforced at 20 and 40 wt-%, but this year the company was back with three new grades. Two featured 10 and 30 wt-% fiber, while a third featured a hybrid of recycled carbon and virgin glass fibers.

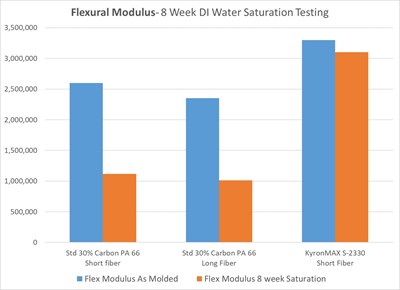

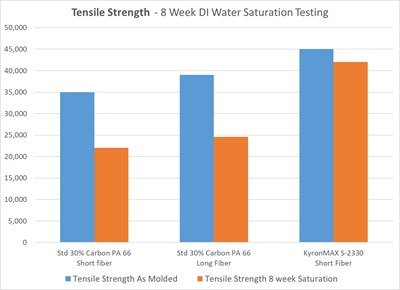

Shown here are the flexural modulus values before and after eight weeks’ water saturation testing using standard PA 6/6 with short CF (left pair of bars) and long CF (middle pair) vs. Mitsubishi’s new KyronMax 2330 (right pair). Source | Mitsubishi Chemical Advanced Materials Inc.

Also introducing new CF/PA grades was a newly formed operating unit of Mitsubishi Chemical Holdings Group (MCHC) called Mitsubishi Chemical Advanced Materials Inc. (MCAM). This business combines two previous companies purchased by MCHC: Quadrant AG (Lenzburg, Switzerland) — which produces glass-mat thermoplastic composites and thermoplastic shapes — and Piper Plastics Inc. (Chandler, Ariz., U.S.) — an injection molder turned compounder that produces injection-moldable, short carbon (6 millimeters/24 K tow) thermoplastics called KyronMax. Available matrices range from PA 6/6 and polyphthalamide (PPA) through high-temperature polyetherimide (PEI), polyphenylene sulfide (PPS), polyetheretherketone (PEEK) and polyaryletherketone (PAEK). Reportedly, a combination of unique sizing chemistry, press modifications and excellent processing have helped these compounds replace not just short-glass and short-glass/mineral thermoplastics and long-fiber thermoplastics (LFTs) but also metals.

Shown here are the tensile strength values before and after eight weeks’ water saturation testing using standard PA 6/6 with short CF (left pair of bars) and long CF (middle pair) vs. Mitsubishi’s new KyronMax 2330 (right pair). Source | Mitsubishi Chemical Advanced Materials Inc.

“Thanks to better flow and fiber interaction, parts molded with KyronMax not only have lower internal stresses and less fiber orientation, but they also have less sink and warpage, stronger weld lines and are more dimensionally accurate in thick or thin sections,” explains Alex Wojtysiak, MCAM key account manager of thermoplastic carbon composites. “Combined, these technologies have helped us introduce the world’s first short-carbon, injection-moldable structural compound that breaks the 60,000 psi [414 MPa] tensile strength barrier.” Introduced at AutoEPCON, that new grade, called KyronMax ES 4240, is 40 wt-% short-carbon PPA.

MCAM also introduced its 2300 S series line, which offers the mechanical performance of CF/PA 6/6 with lower moisture absorption and improved chemical resistance. The matrix is described as polyamide but is neither PA 6/6 nor PPA.

A third product debuting at the show that MCAM specifically developed for automotive underhood applications is a higher-temperature CF/PPA grade with both glass transition temperature and continuous use temperature values as high as those for PEEK.

Wojtysiak says that Piper had lacked the resources to target the auto industry on its own, but now that the team is part of Mitsubishi, it’s specifically formulating grades for and deploying people to cover this segment.

AutoEPCON will return in 2020 on April 20 at the Detroit Marriott Troy in Troy, Mich., U.S.

Related Content

Bioabsorbable and degradable glass fibers, compostable composite parts

ABM Composite offers sustainable options and up to a 60% reduction in carbon footprint for glass fiber-reinforced composites.

Read MoreTPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreRead Next

SAMPE 2019: The highlights

CompositesWorld was at SAMPE 2019 and offers a summary of highlights from the show and conference.

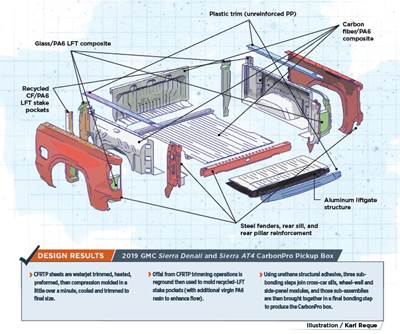

Read MoreChopped carbon fiber, polyamide and innovation redefine the modern pickup truck bed

CarbonPro, the first thermoplastic composite box, boosts damage resistance, reduces mass 28 kg, scales to high production volumes.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;width=70;height=70;mode=crop)