Bio-based fillers: Reducing SMC mass

The Bio-Lite Technical Center of Excellence at the National Composites Center (Dayton, Ohio) is developing sheet molding compound (SMC) recipes capable of yielding finished parts with specific gravity as low as 1.2.

Sheet molding compound (SMC) has long had a home in a variety of automotive composites applications — to the tune of about 325 million lb (about 147,420 metric tonnes) per year in the U.S. alone. Applications include exterior body panels, including front and rear fenders, hoods, doors and decklids, as well as trunk floor/spare tire wells and other secondary support structures.

A perennial issue with SMC, however, has been its weight efficiency. Conventional formulations in use today range in specific density from 1.5 to 1.9 or more. There are a number of efforts underway to drastically reduce SMC’s specific gravity, and thereby, its mass, through the use of bio-based materials.

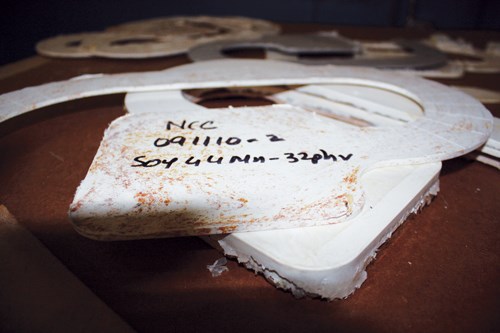

The Bio-Lite Technical Center of Excellence at the National Composite Center (NCC, Dayton, Ohio) is in the midst of a two-year effort to develop optimized SMC recipes that, the Center hopes, will be capable of yielding finished parts with a specific gravity as low as 1.2. As part of that program, the Center is conducting research on several “green” materials technologies that it expects will help manufacturers reduce material weight in automotive composites.

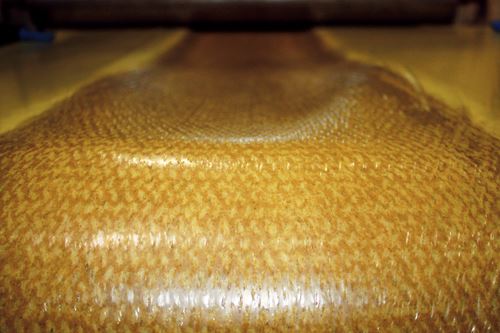

One area of study is centered on fillers. Although several powdered minerals are widely used as filler in SMC — including talc, limestone and calcium carbonate — the most used is the latter, which accounts for 55 percent of the SMC filler market. Therefore, the Center has focused recent efforts on finding a bio-based replacement for calcium carbonate. The goal of this phase of research is to find a bio-based material that will reduce finished part weight by as much as 30 percent.

Leading the research is NCC scientist Dr. Rujul Mehta. He reports that the Center is currently assessing soybean meal, corn-based solids, rice husks, kenaf, silica platelets and recycled cellulose, with special attention paid to soybean meal. (The Center’s research is sponsored, in part, by the United Soybean Board, Chesterfield, Mo.).

Early results are encouraging, Mehta says, noting that, to date, the center has demonstrated potential weight savings with soy-based filler of about 30 percent in a polyester-based SMC. Another test of soy, cellulose and kenaf fillers demonstrated a 22 to 36 percent reduction in specific gravity compared to calcium carbonate. Because of the specific gravity reduction, he says, the center can replace calcium carbonate volume-for-volume, rather than weight-for-weight. This, says Mehta, allows filler loading to be selected independent of final density considerations.

Some technical challenges remain, however. The water take-up of SMC with soy-based filler is about 5 percent, compared to less than 1 percent for SMC with calcium carbonate. Mehta also says that elastic modulus of calcium carbonate-filled SMC is 14 GPa vs. 10 GPa for soy-filled SMC. Similarly, tensile strength drops from 85 GPa to 79 GPa, and apparent shear strength drops from 19 MPa to 18 MPa. Mehta says sizing agents are being evaluated as a way to recover some of the lost modulus.

Mehta reports that real-world automotive applications based on the Center’s research are already in the works and should come to light early this year.

Related Content

Melker of Sweden accomplishes sea kayak with 100% sustainable composite construction

Built with ampliTex flax fabrics, a solid cork core and plant-based resins, the company’s Värmdö kayak model highlights an environmentally conscious design for paddlers of all levels.

Read MoreJEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

Read MoreEuropean boatbuilders lead quest to build recyclable composite boats

Marine industry constituents are looking to take composite use one step further with the production of tough and recyclable recreational boats. Some are using new infusible thermoplastic resins.

Read MoreBcomp ampliTex makes appearance in Cupra EV Cup Bucket seats

The entire Cupra Born VZ line-up features all-natural fiber front seats that highlight functionality, aesthetics and reduced CO2 emissions.

Read MoreRead Next

Resin systems update: The greening of thermosets

Thermoset resin formulators seek environmental benefits as customers demand reduced cost and increased performance.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More