CAMX 2017 preview: A&P Technology

A&P Technology (Cincinnati, OH, US) is showcasing its line of braided fabrics, including QISO, a 0°/±60° balanced and symmetric quasi-isotropic fabric, and Bimax, an off-the-shelf ±45° bias fabric.

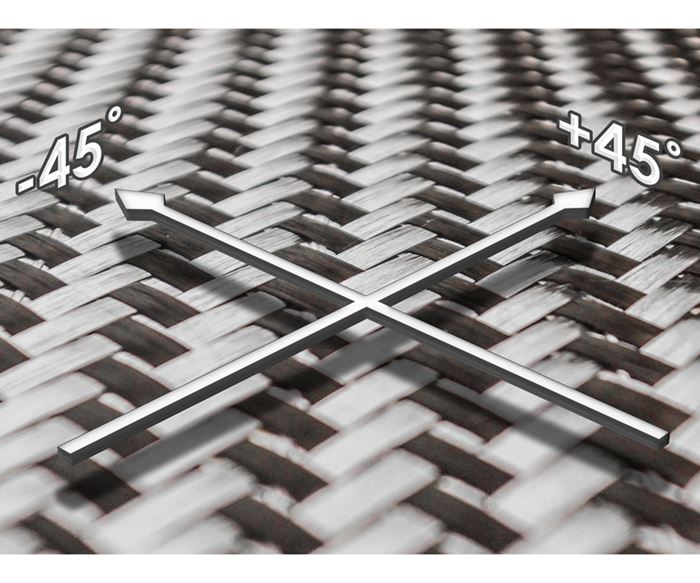

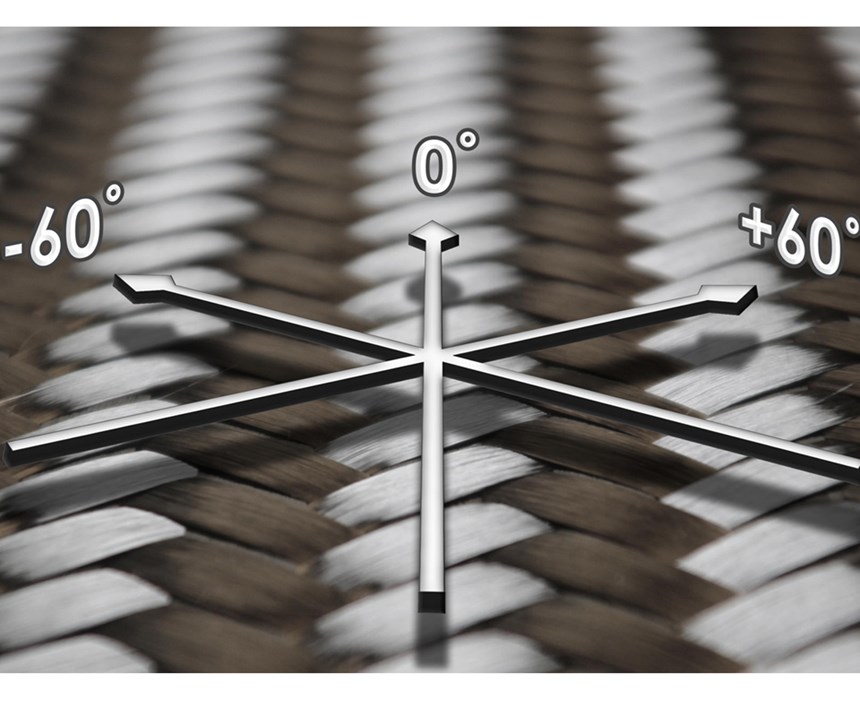

A&P Technology Inc. (Cincinnati, Ohio) is showcasing its line of braided fabrics, including QISO, a 0°/±60° balanced and symmetric quasi-isotropic fabric, and Bimax, an off-the-shelf ±45° bias fabric. Both fabrics are being adopted in a variety of industries, including aerospace, tooling and automotive. Compared to parts designed with traditional 0°/90° woven or non-crimp fabric (NCF) reinforcements, A&P says parts made with QISO are stronger, have better impact resistance and have more consistent coefficient of thermal expansion (CTE). QISO is said to improve the manufacturer’s buy-to-fly ratio as its quasi-isotropic architecture simplifies kitting and enables the use of fewer plies compared to the traditional 0°/+45°/-45°/90° layup. The purchase price of QISO is comparable to woven materials and A&P says manufacturers have realized a process savings between 20-30% using QISO.

With Bimax, instead of cutting 0°/90° on the bias to create 45° materials, manufacturers can use this off-the-shelf ±45° drop-in replacement. Bimax is said to enable consistent part layup and reduces material waste. A&P’s fabrics are available in a range of areal weights and widths and can be customized to meet exact part requirements. A&P fabrics can be made with almost any fiber type, and are sold dry or as a prepreg. CAMX 2017 booth H2.

Related Content

-

CSub delivers one-piece composite truss bridge in Norway

EPC supplier has fabricated, transported and delivered a 42-meter composite bridge intended for pedestrians and bicyclists.

-

Designing an infused, two-piece composite baseball bat

With its Icon BBCOR bat, Rawlings leveraged its experience in braided fabrics and RTM to create an optimized, higher-performance two-piece design.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.