CAMX 2017 preview: Siempelkamp

Composites machinery specialist Siempelkamp (Krefeld, Germany) is featuring its compression equipment for sheet molding compound (SMC), phase change material (PCM), resin transfer molding (RTM) and thermoplast forming.

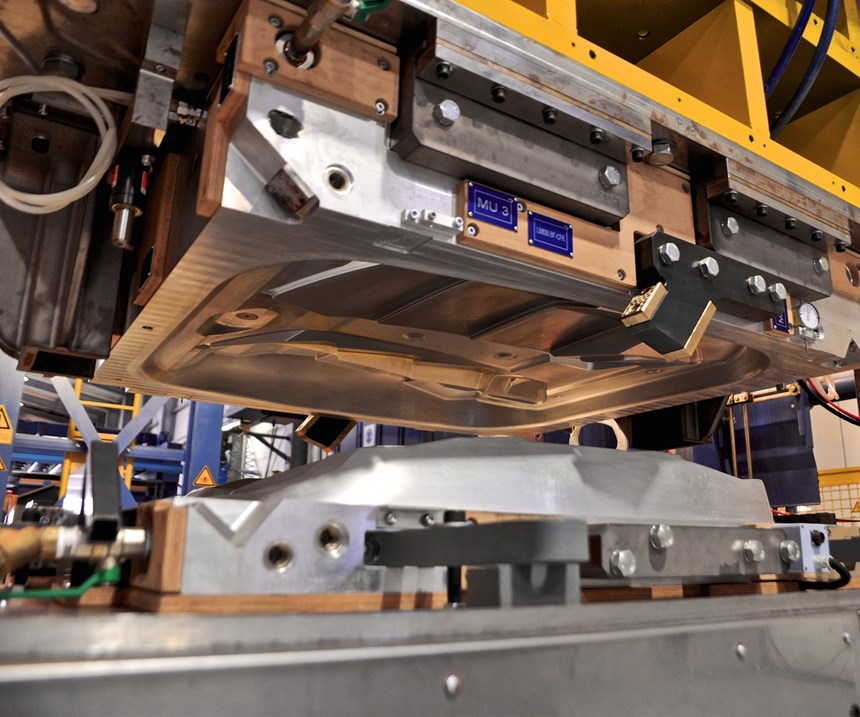

Composites machinery specialist Siempelkamp Maschinen- und Anlagenbau GmbH (Krefeld, Germany) is featuring its compression equipment for sheet molding compound (SMC), phase change material (PCM), resin transfer molding (RTM) and thermoplast forming. Tonnages for these machines range from 150 tons for lab applications and up to 3000 tons for complete production lines. Features include good closed loop control of the ram plate, with fast closing and high accuracy. Siempelkamp also provides complete solutions including peripheral systems for handling, loading and unloading as well as post-processing. Booth F83.

Related Content

-

Plant tour: Arris Composites, Berkeley, Calif., U.S.

The creator of Additive Molding is leveraging automation and thermoplastics to provide high-volume, high-quality, sustainable composites manufacturing services.

-

Composite molding compound replaces Invar for lightweight small satellite structures

Patz Materials and Technologies and Lawrence Livermore National Laboratory developed a new monolithic optics housing with 80% less weight, near-zero CTE and the high-volume manufacturing required for commercial space.

-

Hybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.