Composite molding compound replaces Invar for lightweight small satellite structures

Patz Materials and Technologies and Lawrence Livermore National Laboratory developed a new monolithic optics housing with 80% less weight, near-zero CTE and the high-volume manufacturing required for commercial space.

Iterating to optimize molded composite design. Patz Materials & Technologies worked with Lawrence Livermore National Laboratory to iterate through (top to bottom, at right) V1, V7 and V10 designs for composite housings to support monolithic optics used in small satellites. Photo Credit: NASA, Lawrence Livermore National Laboratory Space Institute and Patz Materials & Technologies

The space industry is growing. According to a January 2023 McKinsey report, the number of small satellites launched per year will ramp from 1,740 in 2022 to more than 3,000 in 2030, and space consulting firm NSR has projected that 24,700 satellites will be launched between 2021 and 2030. “Instead of building one satellite each month, the commercial space industry is now building hundreds per month,” says Nick Patz, president of Patz Materials & Technologies (Benicia, Calif., U.S.), a developer and manufacturer of advanced composites with more than 20 years of flight heritage in the space industry. “We have supplied high modulus, high-performance carbon fiber-reinforced prepregs to manufacturers of large satellites for many years, but the paradigm has changed. You can’t spend two weeks making a single part when you’ve got hundreds of parts to make each month. And even though the size of these satellites is much smaller, they still require the same properties: high modulus, high strength, low density and low coefficient of thermal expansion [CTE].”

In response, Patz Materials has developed a specifically tailored carbon fiber/epoxy molding compound. “We took a lot of the technology that we developed for the large satellite community and put it in a processing methodology that can keep up with the manufacturing tempo for commercial space,” explains Patz.

Figure 1. Small satellites increase need for materials with low CTE and density. Monolithic optics like the V3 (3-inch/8.5-centimeter aperture) unit from LLNL shown here (bottom) have used low-CTE Invar housings to ensure camera accuracy. However, today’s increased volume of small satellites (top) require materials with lower density, cost and lead times. Photo Credit: LLNL

The small satellite hardware development team within Lawrence Livermore National Laboratory’s (LLNL, Livermore, Calif., U.S.) Space Program has also been advancing technology for small satellites. Since 2012, LLNL has been developing optical imaging payloads for cube satellites (cubesats, measuring 10 centimeters per side) for monitoring space debris and other missions. Compared to conventional designs with independent primary and secondary mirrors, LLNL has developed a monolithic optic that combines these mirrors into a single element (Fig. 1). These monolithic optics fit the tight package space of small satellites yet are robust enough to handle vibration loads during launch and temperature extremes in space. However, they require a housing that has a very low CTE. Currently, that is achieved using Invar, which has a CTE of ~1.3 (micrometer/meter)/ºC. A 36% nickel alloy with iron, Invar is also heavy, expensive and requires lead times of multiple months.

In 2021, Patz Materials and LLNL teamed up to replace Invar in these monolithic optic housings with a molding compound comprising PMT-F16 epoxy resin modified with carbon nanotubes (CNT) and reinforced with 6K tow high modulus carbon fiber with 60% fiber content. The project demonstrated not only the ability to meet all metallic housing performance requirements at a fraction of the weight, but also provided even further benefits when the housing was redesigned to take advantage of the composite material and molding process.

Weight savings, optics housings and Invar

“Weight is always an important part of getting a payload to space,” notes Jordan Smilo, mechanical engineering manager for optical payload systems at LLNL. “But as these payloads decrease in size, the mass allowance shrinks. Before, we counted kilograms, but now we’re counting every single gram.”

Decreasing mass also has cascading benefits. “The rocket needs to lift the satellit mass into orbit, but more mass means more force, requiring the structures that hold that mass to be stiffer and heavier,” notes Smilo. “Conversely, by reducing the mass of the satellite, less force is exerted on its internal structures, and now they too can be lighter. These satellites are also fit into dispenser mechanisms which have limits on how much mass they can hold — again, related to force generated during launch and also the vibrational shocks developed. Reducing mass — which the composite molding material does quite significantly — allows us to put more capability into the given volume the dispenser can support and launch into space.”

If light weight is so important, why use Invar? “The only thing we like about Invar is that it has a very low CTE,” explains Frank Ravizza, lead optical engineer for monolith telescopes at LLNL. “Materials like aluminum expand significantly as temperature changes, while Invar does not. Optical systems must be robust to the temperature extremes in space; nobody likes out-of-focus pictures from an expensive satellite. Invar allows us to hold the optical components where they need to be, precisely spaced and oriented within their housing.”

“Invar is also difficult to work with and requires a series of heat treatments throughout the machining process, which costs a lot of money and time,” adds Smilo. “And even then, the final shape may move over time. Our goal was something that offers a steel-like strength but is easier to work with and remains stable with changing temperature over time. But we also thought that if we’re clever, we might be able to enhance other properties as well.”

Proof of concept, CNT-modified resin

V1 housing molded by Patz using its carbon fiber/ epoxy molding compound. Photo Credit: Patz Materials and Technologies

Ravizza explains that LLNL agreed with Patz to start with a simple part to demonstrate that the composite material could achieve the low CTE required, “and enable us to move quickly from a concept to a fabricated part that we could integrate with one of our optics.” The first part was a simple cylinder designed to replace the current Invar housing for the V1 optic (1-inch/2.5-centimeter aperture). Patz molded the part and performed testing for CTE. It also tested bolt pull-out for the housing’s molded-in threaded inserts used to position the monolithic optic.

Overall, the part performed well, but some of the bolt pull-out results were lower due to a lack of reinforcement material in the threaded inserts. “This was due to the thin walls the molding compound had to form around the knurled insets,” explains Jess Bernhard, technical program manager at Patz.

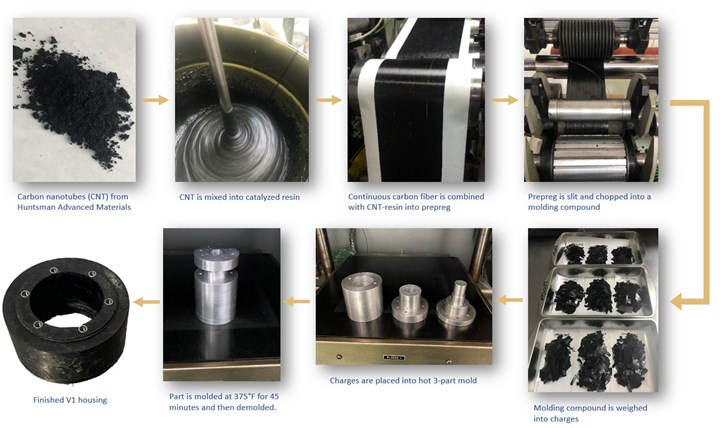

“We did a lot of resin development, looking especially at toughness,” says Patz. The team decided to use Miralon CNT materials from Huntsman Advanced Materials (The Woodlands, Texas, U.S.). This technology was developed by Nanocomp Technologies and acquired in 2018. As described in the sidebar above, the Patz molding compound is a unidirectional prepreg that it makes and then chops into short ribbons (Fig. 2). “At the ends of those ribbons, you basically have pools of resin,” says Patz. “So, the resin attributes were dominating a lot of the molding compound’s properties. CNT materials have been shown to provide excellent improvements in resin properties, and we use them to improve the molding compound’s ability to transfer load in between the prepreg fiber bundles in those resin-dominated locations. So, it’s a CNT-reinforced epoxy composite inside of the carbon fiber/epoxy composite molding compound.”

Figure 2. From CNT to molded composite housing. This diagram shows the process steps use by Patz to produce its PMT-F16+CNT/HM63 compound and a molded V1 optics housing. Photo Credit: Patz Materials & Technologies

And that composite also helped to solve the issue with the threaded inserts. “We had images where we could see the fiber would nest around these threaded inserts,” says Patz. “So, it was just resin there, which was weaker. But the CNT intermixes well with the resin, achieving good insert pull-out strength.”

Complexity of molding V7 design

For the next step, the team decided to mold a housing for their V7 optic (7-inch/18.5-centimeter aperture). “We provided Patz with the CAD model of this Invar part, and they attempted to mold it using the composite compound, which presented a number of challenges,” says Ravizza.

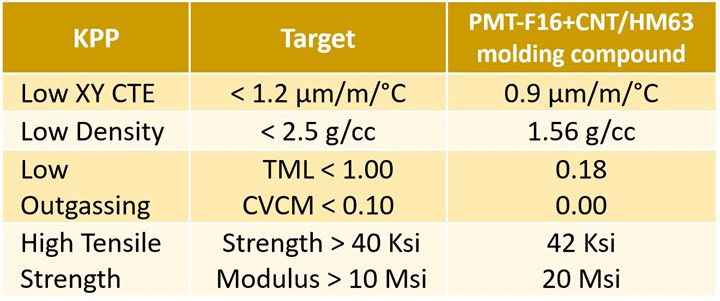

“The V7 housing wasn’t just larger, it was also more complex, with two pieces held together by more than 40 fasteners using four different types of molded-in inserts,” says Bernhard. “The key issue was just molding the design. The compression molding process itself can be pretty challenging, especially to produce very intricate parts and for this type of closed cylinder.” The material properties needed were calculated and became the key performance parameters (KPP) for the molding compound in this application (Fig. 3).

Patz succeeded in molding the V7 housing. “And it demonstrated that they had the capability to make a complex part,” says Ravizza. “However, what we decided going forward for larger parts, was to make them into separate pieces and bolt them together in a ring-type structure. The idea was to design parts which were more appropriate for molded composites versus machined metal.”

“The V7 part was a middle step in that process and the peak of our complexity curve,” he continues. “From that point forward, and based on that experience, we designed parts that were optimized for the composite molding compound and ultimately, were a better design. We ended up with a more robust way of holding the optic, and it was really a mutually beneficial exercise to transition from a complex design which had some limitations to a design that was lower in complexity and more functional.”

“I’ll sing the praises of that V7 design, in that it was really a one-for-one replacement,” says Smilo. “There were no geometry changes from the Invar to the V7 composite counterpart and Patz Materials was able to figure out how to do that in a very complex molded part that survived our testing.” It also reduced weight to 1/5th of the equivalent Invar part. The two-part Invar housing totaled 6.0 pounds while the composite version totaled 1.3 pounds. “So, it was a success,” adds Smilo, “but process-wise, we knew we could make the manufacturing easier and also better optimize the design’s use of carbon fiber.”

Optimizing for composites

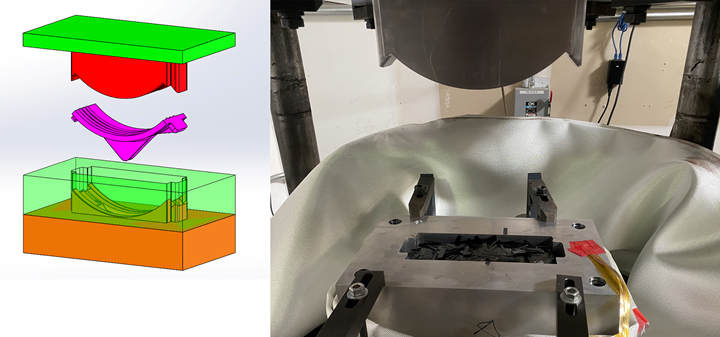

Bernhard summarizes the overall development: “The housing design went from a single piece to a two-piece design and then to the final larger housings, which used a four-piece design incorporating new technology for how to hold the optics, which has multiple benefits.” This four-piece design is being used for LLNL’s V10 optic (10-inch/25-centimeter aperture). A key driver for this housing was simplifying the molded part, which began with tooling (Fig. 3).

Figure 3. Successful V10 composite housing. Key performance parameters (KPP) were defined based on the V7 design (top). Tooling was then redesigned (center) collaboratively for the larger V10 housing that LLNL had designed as a four-piece ring (two pieces are shown here, bottom) to achieve a more robust optics support but also simpler tooling which produced better parts. Photo Credit: Patz Materials & Technologies, LLNL

“It’s always challenging when the initial goal is to just replace metal,” says Patz. “You’re designing around subtractive manufacturing which has a certain toolset, set of rules and way of design. But when you’re designing around composites, especially compression molded composites, it’s a different set of rules and toolset. You’ve really got to work with the customer and help guide them in terms of how the materials are used, where their advantages are and then how to design the structure to exploit those to achieve optimum performance.”

Patz explains that the transition from the V7 to the V10 part involved a review of the tooling. “LLNL had given us a CAD drawing of the part and we showed them the resulting mold was expensive because of the complexity that had to be machined into the metal compression molding tool. So, they could see the impact of design options, such as certain types of angles. And then we started to discuss that we could make a simpler mold which would not only be less expensive, but also make better parts. It was a collaborative process.”

“That really does highlight the difference between the V7 and V10 housing,” says Smilo. “The V7 was a blind replacement for Invar while the V10 was an iterative collaboration to really get the benefits from the composite material and molding process. Our goal was something easy to manufacture.”

A parallel development took place within the LLNL monolithic optics team. “The new V10 design also emerged from our research last year into an entirely new way of mounting larger optics,” explains Ravizza. “In parallel to actually producing the composite V7 design, we also used metal components to test this new approach that reduced complexity and made the design more robust. So, the V10 design was really the coming together of improved tooling, molding and this new approach for how we support the optics.”

Divorce from Invar, success via partnership

V10 optics housing molded using PMT-F16+CNT/HM63 molding compound. Photo Credit: Patz Materials and Technologies

Tooling for the V10 composite housing was machined from aluminum, scaled to accommodate its expansion at the 375°F press molding temperature. V10 parts were then molded using a charge weight of 390 grams. They were bolted together and tested successfully, including vibration testing. Weight for the V10 housing was again reduced to 1/5th that of Invar: 17.5 pounds for Invar to 3.5 pounds using the PMT-F16+CNT/HM63 molding compound.

“Going forward, we can divorce ourselves as much as possible from using Invar,” says Ravizza. “That’s a tremendous benefit to the program not only for cost, but for lead time, because like mass, delivery time is a killer in the small satellite industry.”

Smilo notes that Invar parts are hard to get any faster than 8 weeks, “and it’s typically closer to 12 weeks. But with the Patz molding compound, once we have a design done, we’re able to get these parts turned around with a new mold and whatever post-processing is required by us, in a matter of 3-4 weeks. And when we want to make a second part, we’re simply molding new parts and we’re able to shave lead time down even further.”

He notes that some in the space industry believe there must be a tradeoff with this type of weight and lead time reduction. “They think you have to give something up, but we’re not seeing that with our parts. This composite housing is stronger, lighter, cheaper and faster — and not just by a week or two, but months faster. We’re in the business of trying to make satellites very quickly, in a responsive fashion. Having something that can be provided in a weeks-to-month timeframe versus several months can make the difference for a program win.”

What was the biggest challenge? “It wasn’t necessarily a materials challenges,” says Patz, “but being able to work together to utilize the material in the most optimum way to provide the best benefits.” LLNL agrees. “I think the story here is the partnership between Patz Materials and our team at LLNL,” says Smilo, “and our collaboration to overcome the issues for insertion of these materials onto space platforms.” Ravizza adds, “although the use of composites has a compelling case, the reason why we had success is that we’ve been able to develop a good design, but that required an iterative process and also the Patz team’s knowledge and willingness to keep working on this.”

Future developments, composite radiators

Ravizza believes that his team at LLNL were the perfect partners for this type of development because their role is to do R&D and push the capabilities of new technologies, “and the small satellites that we’re developing are a good proving ground. But we see opportunity to expand this material and approach beyond that.” He concedes there may be more process control and rigor required for composite materials, because of how they’re manufactured versus a metallic part, “but those issues can be overcome with proper quality assurance.”

“We are looking to transition all the metallic components over to composite materials where they make sense,” Ravizza continues. “Not just optics, but the supporting elements that are key to making a functional payload. And we’d like to transfer this technology and get it into the hands of industry.”

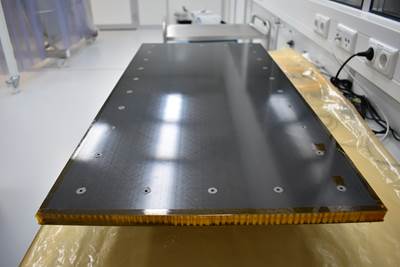

Smilo agrees. “As a mechanical engineer who is also very close to the build schedule of the project, I’m interested in how we can replace all involved parts with something that is faster to produce, while still maintaining the kind of reliability needed.” Here, he gives an example, saying, “We’re currently working on a carbon fiber radiator, which takes heat from inside the payload and dissipates that to the outside environment.” To achieve this, the molding compound was modified to use pitch-based fibers instead of the standard PAN-based fibers to increase the thermal conductivity to numbers much higher than aluminum. Patz adds that this can be done at a lower density while retaining all the other required properties for space applications.

Smilo notes that in this case, the composite isn’t being used for its strength properties, but purely for its ability to transfer and reject heat from the payload. “That’s not the classic way to use carbon fiber, but we’re able to benefit from the high thermal conductivity of the fibers and with some intentional design and orientation of the fibers, we can use this material as a radiator panel.”

“Thermal management is a big concern in space systems where temperature can have adverse effects on optics and other equipment,” explains Ravizza. “In space, you are in a vacuum, so the only way to reject heat is through gray body radiation which requires surface area. And copper, though one of the best metallic thermal conductors, is a high-density material. So, for this area of thermal systems, copper would be the analog to Invar. This is a really exciting area that we’ve just started to investigate. We have produced a first example of a radiator using this higher conductivity composite that Patz developed and we’re now testing it.”

“We’ll see more such projects going forward,” says Patz. “We see this molding compound being adopted into more applications as commercial space grows and more and more parts are needed.”

Related Content

Carbon fiber satellite arm reduces weight, simplifies assembly onto naval vessels

Satcom developer EM Solutions partnered with ACS Australia to replace an aluminum arm design with a 65% lighter, one-piece, corrosion-resistant carbon fiber/epoxy alternative.

Read MoreRocket Lab begins installation of large AFP machine for rocket production

The 99-ton AFP machine, custom-designed and built by Electroimpact, is claimed to be the largest of its kind, expecting to save around 150,000 manufacturing hours in the Neutron rocket’s production process.

Read MoreLow-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreRead Next

Multi-composite thrust chamber aims to boost rockets, reduce cost for New Space economy

Black Engine uses new, microporous CMC liner for transpiration cooling and multiple lightweight composites in modular design that offers increased lifetime and lower maintenance versus current launch vehicle engines.

Read MoreInvar, wire additive manufacturing expand aerocomposite tooling options

Invar facesheets and backing structures are candidates for large-format 3D printing to more quickly and efficiently produce aerostructures tooling.

Read MoreNanomaterials optimize performance of space-ready carbon fiber composite panels

A recent ESA project led by Adamant Composites aimed to mature nanomaterial-enhanced CFRP for lighter weight, more thermally and electrically conductive materials for manufacturing satellite structures.

Read More