CAMX 2018 preview: Airtech

Airtech International Inc. (Huntington Beach, CA, US) is introducing several new products this year in Booth V3.

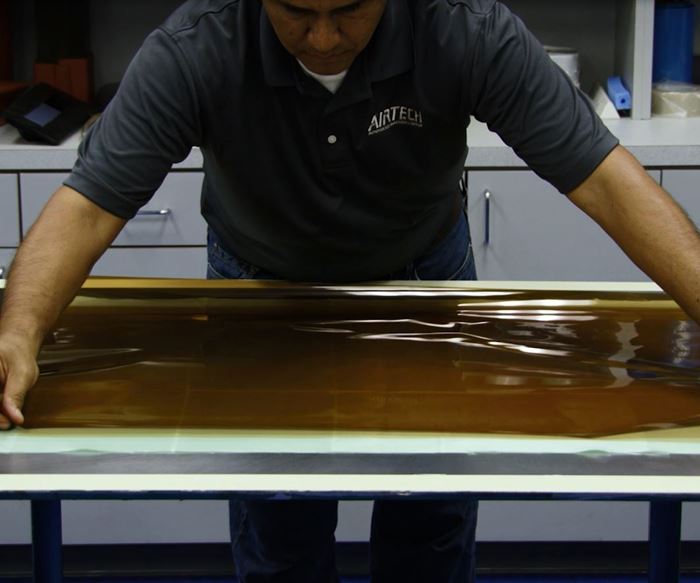

Airtech International Inc. (Huntington Beach, CA, US) is introducing several new products this year in Booth V3. Fast Tack HT is a sealant tape for high-temperature applications that builds tack quickly when applied to Thermalimide. Benefits of the tape include a high-temperature resistance film, excellent release off cured parts and flexibility for applying pressure over simple contoured shapes. Thermalimide RCBS is a high-performance release film treated on both sides for cure temperatures up to 761°F/405°C. It is designed for use with thermoplastic materials and other high-temperature materials.

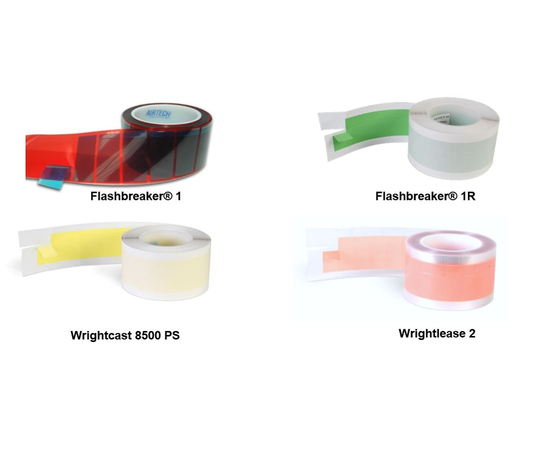

Airweave UHT 300PGL and Airweave UHT 450PGL are premium nonwoven, blended, fiberglass breathers for ultrahigh-temperature applications. They reportedly provide a smooth transition for the vacuum bag in any radius. One layer provides good breathing to 800°F/427°C, for use with high-temperature thermoset and thermoplastic resin systems. Also new are Pre-Cut Tape Strips, designed to reduce touch labor and minimize the use of knives and scissors. In addition, the strips eliminate the possibility of damaging the vacuum bag. Airtech can customize and offer pre-cut strips for almost any pressure-sensitive tape, including its Wrightlease 2, Wrightcast 8500PS, Flashbreaker 1, Flashbreaker 1R and more.

GS-333LT sealant tape has been designed for clean removal after a long cure cycle. It is suitable for temperatures up to 400°F/204°C. Beta TX670 DISCO is a prepreg sold in sheet format, in 0°/±60° orientation. It comes with an engineered cut pattern that is said to improve drapability. Combo-Tech Combination Products combine peel ply, release films and/or breathers in wide widths and can be slit to custom sizes. A4000 LFST is a heat-shrinkable lay-flat tube for mandrel protection applications. When exposed to heat of 249-348°F (121-176°C) in a recirculating oven, tunnel oven or from a heat gun, the A4000 LFST material will shrink to closely fit a mandrel. It is said to be ideal for providing a self-releasing cover for mandrels used in fabrication of hollow composite parts.

Related Content

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

-

Optimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.