CAMX 2018 preview: Volume Graphics

Volume Graphics's VGSTUDIO MAX software performs precise metrology tasks, compares parts with their nominal CAD model and detects discontinuities based on CT data.

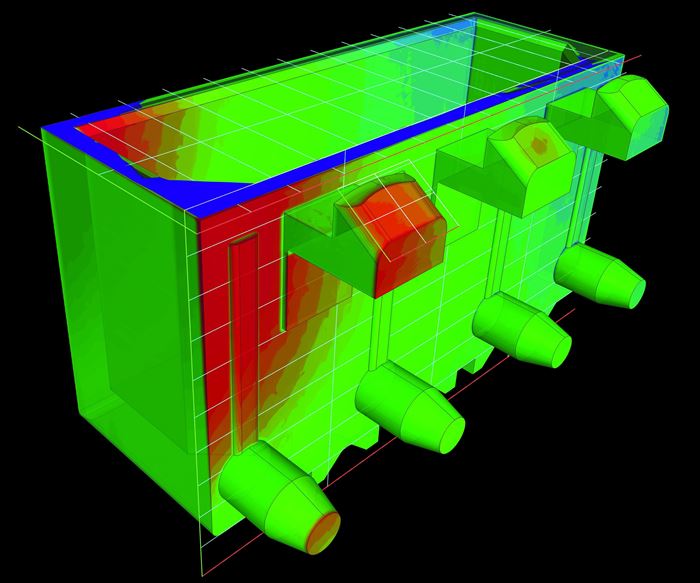

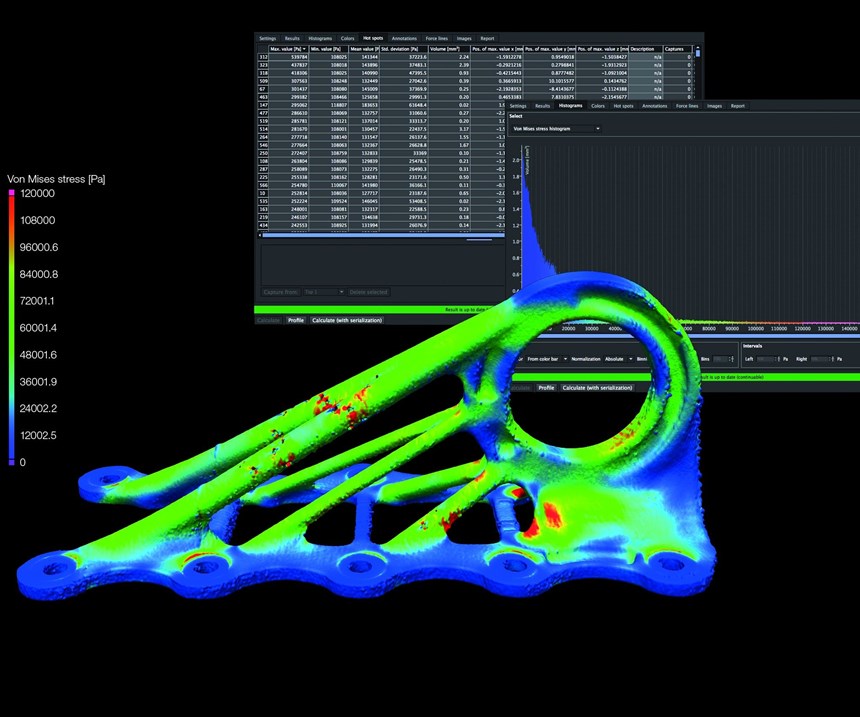

Volume Graphics's VGSTUDIO MAX software performs precise metrology tasks, compares parts with their nominal CAD model and detects discontinuities based on CT data. The latest version, VGSTUDIO MAX 3.2, offers new options for tool and geometry corrections and a more meaningful assessment of mechanical effects of porosity. It also allows users to predict how much force a part could theoretically withstand, solely based on a CT scan. The software offers analysis, simulation, and visualization tools.

The software’s optional Manufacturing Geometry Correction Module combines the manufacturing, testing, and correction of tools and components into a seamless digital workflow. It is said to be a cost-effective, easy-to-use and versatile method for tool correction, surface reconstruction of a manually reconstructed tool and part correction of 3D printing geometries. The optional cutting-edge Structural Mechanics Simulation Module helps users take the results of a porosity analysis into account in a structural mechanics simulation. Booth L30.

In addition to the show exhibit, Karl-Michael Nigge, Volume Graphics’ head of product management, is presenting “Simulation of the Notching Effect of Pores in 3D Printed Components,” Oct. 18, 10:30 am, D223/224.

Related Content

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

-

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

-

Nine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

.jpg;width=70;height=70;mode=crop)