Carbon fiber reclamation: Going commercial

As the first commercial-scale carbon fiber recycling operations go online, research continues into both recycling alternatives and applications for recyclate.

Almost from the moment aircraft manufacturers The Boeing Co. (Seattle, Wash.) and Toulouse, France-based rival, Airbus, signaled their intention to reduce fuel consumption and emissions by incorporating more lightweight composites into new airplane designs, an array of universities, laboratories and for-profit enterprises have been involved in researching and developing ways and means to recycle them.

One big reason recycling has assumed such a high profile is that airframers, owing to a long history of working with aluminum and other metals, already had achieved an enviably high metal-recycling rate, says Carl Ulrich, managing director, Allstreams LLC (McLean, Va.). That explains, in part, why Boeing and Airbus have been integrally involved in much of the research into carbon fiber recycling over the past several years. Each Boeing 787, for example, carries approximately 40,000 lb/18,144 kg of salvageable carbon fiber. Boeing, with its industry partners in the Aircraft Fleet Recycling Assn. (AFRA, Washington, D.C.), and Airbus, through its Process for Advanced Management of End-of-Life Aircraft (PAMELA) consortium, are looking to increase the amount of aircraft recycled material from roughly 70 percent today to upwards of 90 percent in the coming years.

Revenue-capable and responsible

“Carbon fiber recycling is an attractive market niche because it's driven not just by the financials, but also by government research incentives, and by the desire for manufacturers to have green manufacturing processes and products,” explains Ulrich.

Jim Stike, the CEO of recycling firm Materials Innovation Technologies (MIT, Fletcher, N.C.) contends that carbon fiber recycling, in fact, offers “three shades of green.” It not only prevents the waste of virgin carbon fiber in landfills after its first use, but components produced using the recycled fiber are themselves recyclable, because carbon can retain a significant portion of its virgin properties even after a second reclamation. Further, the recycling process itself significantly reduces energy costs. Boeing estimates that carbon fiber can be recycled at approximately 70 percent of the cost to produce virgin fiber ($8/lb to $12/lb vs. $15/lb to $30/lb), using less than 5 percent of the electricity required (1.3 to 4.5 kWH/lb vs. 25 to 75 kWH/lb).

Given this potential, a number of viable mechanical and thermal recycling techniques are in various stages of development, an R&D history chronicled along the way in HPC (see first two items under "Editor's Picks," at right, and the sidebar at the end of this article). But one clear leader has emerged. “Pyrolysis, with and without the aid of a catalyst, seems to be the front-running technology at the present,” says Bill Carberry, program manager for Boeing's Airplane and Composite Recycling. “There are some other technologies in development that include supercritical fluids and microwaves, but these are still pretty much in the laboratory scale.”

Most recently, Airbus and its PAMELA consortium used pyrolysis to extract carbon from an A380 airframe. The goal of this phase of the PAMELA project was to take what had been learned during earlier experiments, most notably the dismantling of an A300 airframe, and apply it to the much larger A380 in an effort to scale-up the process and determine best practices for recovering advanced materials, including 55,000 lb (25 metric tonnes) of composites per plane

According to Carberry, there are, at present, only two commercial-scale, continuous production operations in the world, and both use pyrolysis. One is in the United Kingdom and the other in Japan.

In the U.K., Recycled Carbon Fibre Ltd. (RCF Ltd., West Midlands) now operates one of the two. Its plant houses a highly sophisticated 120-ft/37m long pyrolysis machine reportedly capable of recycling approximately 2,000 metric tonnes (4,409,250 lb) of waste material. The system's capacity is approximately 1,200 metric tonnes (2,645,550 lb) of recycled carbon fiber output per year.

In Japan, members of the Recycling Committee of the Japan Carbon Fiber Manufacturers Assn. (JCMA), including Toray Industries Inc. (Tokyo, Japan), Toho Tenax America Inc. (Tokyo, Japan), a member of the Teijin Group, and Mitsubishi Rayon Co. (Osaka, Japan), have formed a joint venture to recycle carbon fiber at a plant owned by Mitsui Mining Co. in Omuta City, which is in Japan's Fukuoka Prefecture. A test plant began operation in 2007, followed by verification in 2008. Reportedly, annual output of recycled carbon fiber at the plant will ramp up from several hundred metric tonnes initially to 1,000 metric tonnes (2.2 million lb) as demand increases. The recyclate, after compounding, is targeted primarily at the consumer electronics and automotive industries.

In Europe, RCF Ltd. is the tip of the iceberg. Potential competitors are moving toward commercial-scale operations. In Germany, for example, Hadeg Recycling GmbH and CFK Valley Recycling GmbH (both in Stade, Germany) have systems in the early stages of development. And Boeing and Alenia Aeronautica (Rome, Italy) continue joint efforts to open a composite recycling operation in Italy.

In the U.S., Adherent Technologies Inc. (Albuquerque, N.M.) plans to open a facility in the near future capable of processing 1,000 metric tonnes (2.2 million lb) of recyclate annually. Firebird Advanced Materials Inc. (Raleigh, N.C.) has developed a proprietary continuous microwave recycling method and plans to begin its commercialization this year. And in Lake City, S.C., not far from Boeing's North Charleston, S.C., fuselage subassembly plant, MIT expects to open a recycling plant by the end of this month. Initially, the 50,000-ft2 (4,645m2) facility will be capable of generating 1 million lb (453.6 metric tonnes) of carbon fiber per year using a pyrolysis process, says Stike. “As we get more scrap, we can add shifts or work cells as needed.”

Martin Spooner, sales and business development manager at RCF Ltd., is quick to stress, however, that even though there is a lot of viable research, testing of pilot machines and talk of upcoming commercial operations, successfully starting up a carbon fiber recycling plant is not as easy as it looks. “It took about six months for us to get our new machine up and running well,” says Spooner. “That was after running a smaller pilot machine for nearly two years,” he adds. “In theory, this is easy to do, but actually doing it in practice and at scale is a very difficult job.”

Securing & controlling feedstock

One obstacle is securing sources for high-quality carbon fiber scrap. In fact, the size of the market for recycled carbon fiber will be determined not by demand, but rather by the availability of supply, says Ulrich.

Spooner sees it as one of the recyclers' biggest challenges. To meet it, RCF Ltd. recently added Leslie Cooke to its U.S. staff. Formerly director of sales/marketing at Tacoma, Wash.-based Toray Industries Inc. (America) Inc., Cooke will, according to RCF's CEO Steve Line, help RCF secure carbon fiber feedstocks from the North American market. Those feedstocks will be processed at the European facility until a forthcoming U.S. plant is operational (circa. 2010-2011).

In the short term, Ulrich estimates a stable potential for 10 million to 15 million lb (4,536 to 6,804 metric tonnes) of carbon fiber recyclate from a combination of process scrap and end-of-life aircraft and parts from the aerospace sector. By 2029, Ulrich estimates the potential to reclaim more than 50 million lb (22,680.6 metric tonnes) of carbon fiber. “The timing of the transportation industry's adoption of continuous CFRP is still speculative, but the impact could be significant if user-friendly materials develop,” he says. In the short term, Ulrich believes the automotive market is more likely to become a big customer base for recycled chopped carbon fiber, rather than a big supply base.

By contrast, wind energy has great future potential as a scrap supply source. “Wind turbine blades are expected to add more than 10 million lb [4,535.92 metric tonnes] of carbon fiber in large units of homogenous fiber,” Ulrich adds. “Recycling of large wind turbine blades will be profitable, attractive targets to the recyclers that win long-term contracts,” he foresees, ”but that is 20 years into the future, at the end of their useful life.”

Another challenge is dealing with the diverse nature of the feedstock. “We can recycle dry waste, prepreg off-cuts, out-of-date prepreg, laminate off-cuts, tooling and end-of-life components,” says Spooner. “We might have high-modulus aerospace scrap or standard-modulus scrap, but we have to treat it all the same.” Processing scrap is the most consistent and continuous source of recyclable materials. For example, as much as 40 percent of a prepreg material can be scrapped during the manufacturing process.

At RCF Ltd., laminates are cut up prior to pyrolysis and the backing must be removed from prepregs. “There is a lot of processing involved in preparing the scrap,” says Spooner, noting that “much of it is done by hand.” When precisely controlled, the pyrolysis process, which heats the composite, in the absence of oxygen, to temperatures ranging from 752°F/400°C to 932°F/500°C, produces a clean carbon fiber that maintains 90 to 95 percent of its original properties. (Harmful gases emitted by epoxy resins during pyrolysis are siphoned off and incinerated, in accord with environmental guidelines, separately from the carbon to guard against fiber damage.)

“The issue for us is the consistency of the raw material and the consistency of the properties of our final product,” says Spooner. “We're using feedstock from aerospace and Formula One that is very good carbon. However, for industrial applications the stiffness can be too great,” he adds. “We try to blend the feedstock in a way that allows for constant properties.”

RCF Ltd. produces both milled carbon fiber (from 100 to 300 microns long) and chopped fiber (3 mm/0.12 inch to 25 mm/1 inch in length). Each batch is tested to ensure it meets the company's minimum standards: tensile strength of 3000 MPa and modulus of 200 GPa.

End-of-life to new life

One compelling aspect of recycling is the potential for manufacturers to optimize usage of the virgin fiber it buys. “There are clear product sustainability and cost advantages when you can take scrap from one manufacturing process and turn it into a feedstock for another part of your product,” Carberry claims, although he admits that the full extent of that advantage is not yet clear. “First, we have to clear the technological hurdles [of working with new technology], and then we have to qualify recycled carbon fiber for use on aircraft before we can begin to forecast the market potential.”

Toward that goal, Boeing worked with RCF Ltd., MIT, the University of Nottingham (U.K.) and Adherent Technologies to produce a proof-of-concept molded armrest using carbon fiber reclaimed from pre-production Boeing 787 parts. Although the short, chopped fibers yielded by recycling processes cannot replace continuous fibers in aerospace manufacturing, they could be used on tertiary aerospace parts. Further, Spooner sees high-quality recycled carbon fiber, milled and chopped, competing well with industrial-grade virgin fiber.

“We can always be competitive with milled and chopped virgin carbon fiber,” Spooner contends. “In theory, we're a little cheaper because we're not affected by carbon fiber prices in the world, and we know our costs to manufacture,” he explains. “Also, we can offer a consistency of supply because we have different supply routes than traditional carbon producers.”

Also in this vein, Stike says that MIT hopes to capitalize on the potential high quality of the recycled chopped carbon fiber, creating an effectively intermediate-modulus material that falls between virgin aerospace- and industrial-grade products. Toward that end, MIT separates carbon fiber scrap by modulus and then chops it to one-inch lengths prior to pyrolization. Stike reports that the company has worked with a number of major compounders to qualify its reclaimed material for use in compounded materials. MIT also plans to use much of its reclaimed fiber in-house, to manufacture complex fiber preforms for part manufacturers via its proprietary three-dimensional (3-D) engineered preform (3-DEP) process.

“The real value-added prospect for us is to feed our downstream processing in order to make preforms out of chopped fiber,” explains Stike, noting that MIT recently demonstrated this potential, dismantling and recycling carbon fiber from an F-18 stabilator provided by Boeing. Using its 3-DEP process, MIT produced a preform that was subsequently molded into a finished proof-of-concept wheelhouse for a Chevrolet Corvette by Molded Fiber Glass Co. (Ashtabula, Ohio). “We are currently working with potential end-users in both the automotive and aerospace industries,” says Stike (see photos, at right).

According to Firebird's president Thomas Hunter, however, carbon fiber recyclers who target end-uses will face several challenges along the way: “A lot of research has been done in the area of recycling the carbon fiber,” he says, but points out that “this research hasn't really focused on product applications.”

Typically, he contends, fiber produced from pyrolysis is not well suited for most molding operations without further treatment. Although the pyrolysis process creates a very active surface on the carbon fiber, which can promote good fiber/resin bonding, the process also removes the sizing and results in a fluffy, “cotton ball” of fibers. Firebird is working to fine-tune its microwave recycling technologies to produce raw recycled fibers that more closely resemble virgin fiber, says Hunter (see photo comparison, at right).

“You can't put a fluffy, dry fiber into a thermoplastic [compounding] machine, because it won't work,” Spooner agrees, and he believes that stepping beyond the recycling of raw fiber to facilitate new product development will be critical to widespread customer acceptance. RCF Ltd., for example, has compounded its milled and chopped fiber into thermoplastic pellets for injection molders. But Spooner also recognizes that such efforts are ultimately too narrowly focused. “We would like to get our fiber back into a broadgood,” he explains. “The composites market understands mats, not pellets or bags of fiber, so developing a mat-like product is something we feel like we must do,” he adds.

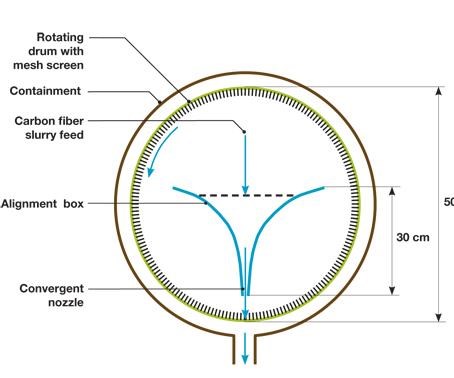

Boeing's Carberry, however, sees fiber orientation as a priority. “The recycled fiber strength and surface structure compares very favorably with virgin materials, with the exception that the fibers are short and random,” says Carberry. “The key to unlocking the manufacturing future for recycled fiber beyond injection molded applications is aligning the fibers.” Boeing is collaborating with others to develop that technology. In the same vein, Researchers at the University of Nottingham (U.K.) formed a roughly unidirectional fiber mat, using reclaimed discontinuous carbon fibers and a relatively simple fiber-alignment process (see the illustration at right, and see “Editor's Picks”).

Coordinating generator/recycler efforts

Although reclaimed scrap carbon fiber has a good deal of inherent value, all agree that cooperation between the scrap generator and the recycler will result in higher quality feedstocks and, therefore, a higher-quality recycled fiber that will retain more of that inherent value. Hunter suggests that greater involvement of the waste generator, in terms of material sorting and scrap component size-reduction, will reduce the risk of contaminants in the scrap and reduce the processing burden on the recycler.

Increased collaboration between carbon fiber recyclers and large scrap producers could dictate to some extent where recyclers build their plants, says Stike. “We envision building facilities in locations where the scrap is generated,” he says.

“You can't treat carbon scrap like it's aluminum being recycled for $1/lb,” Stike sums up. “If you're serious about this material, you need to take care of it on the front end. You have to treat it like it's an advanced material and realize that it can be reclaimed and the properties can be maintained.”

Editor's note: The University of Nottingham fiber alignment experiment described here was outlined in a paper entitled “Characterization of Reclaimed Carbon Fibers and their Integration into New Thermoset Polymer Matrices via Existing Composite Fabrication Techniques,” by Brian Edward Allen, (North Carolina State University (Raleigh, (N.C.), 2008, posted at www.lib.ncsu.edu/theses/available/etd-03172008-162622/unrestricted/etd.pdf.

Related Content

Henkel releases digital tool for end-to-end product transparency

Quick and comprehensive carbon footprint reporting for about 58,000 of Henkel’s adhesives, sealants and functional coatings has been certified by TÜV Rheinland.

Read MorePark Aerospace launches aerospace, MRO structural film adhesive

Aeroadhere FAE-350-1 is a curing epoxy formulation designed for composite, metal, honeycomb and hybrid applications.

Read MoreSyensqo introduces AeroPaste 1003 aerospace adhesive

Two-part room-temperature paste increases high-rate assembly and joining efficiencies when bonding metallic and composite parts.

Read MorePRF Composite Materials introduces primer, adhesive films

Novel RFA570 eXpress cure adhesive film and RF Primer are compatible with PRF’s full range of epoxy prepregs formulations.

Read MoreRead Next

Carbon fiber: Life Beyond the Landfill

Reclamation technologies give scrapped aerospace-grade carbon fiber new possibilities and a lower price point in nonstructural/conductive applications.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More