Carbures, el Puerto de Santa Maria, Spain

On a rapid and audacious growth trajectory, this Tier 2 supplier based on the Iberian Peninsula opens the doors of three foundational facilities near Spain’s aerospace epicenter.

Growing a business in today’s global economy takes skill, know-how, courage and a lot of hard work — particularly if your enterprise involves supplying carbon composites to multiple markets. Such is the case with Carbures (El Puerto de Santa Maria, Spain), a Tier 2 composite part supplier to Airbus (Toulouse, France) and a long list of additional aerospace, rail transit, automotive and infrastructure clients.

The company has grown significantly from its beginnings in 1999 as a University of Cadiz spin-off, working for Airbus on a resin cure problem (read more located under "Editor's Picks" on the top right). Today, its nearly 1,000 employees work in 18 locations worldwide, organized into three business units: Aerospace and Defense, headed by Javier Moreno; Civil Works, headed by Raúl Garcia; and the company’s newest unit, Mobility, headed by Josef Neuhäusler, all under the leadership of chief executive officer (CEO) Roberto Rey.

Carbures invited CW to visit three of its busiest facilities, located in Spain, to see and understand its operations first hand. Two are part of the Aerospace and Defense group, and the third houses Mobility operations.

Jerez — Aerospace and Defense

CW’s first stop is Carbures’ 7,700m2 facility in Jerez de la Frontera, adjacent to the city’s airport, a few miles from the company’s birthplace in Cadiz, near the southern tip of Spain. Built in 2013, it’s considered an extension of the company’s original Technobahia prototyping and production center, built in 2004 a few miles away in El Puerto de Santa Maria. Technobahia came about when Carbures, after its post-university startup period under its previous name, Easy Industrial Solutions, merged with a local firm, Atlantica Composites, and began work with an Airbus Tier 1 supplier. The Technobahia facility obtained Airbus Military certification in 2005, and received its first Airbus work packages around 2006. In the seven intervening years, more than six-fold expansion necessitated the new building. Says Álvaro Gonce Gómez, its head of manufacturing, “In 2012, our operating budget was €1.3 million [US$1.46 million] with just the Technobahia facility, and by 2015 it had increased to €8.3 million [US$9.38 million]. We’ve added some significant customer parts to our workload over the last several years, and needed to expand.”

To ensure a pool of trained workers in the region, the company works with a school in El Puerto, providing internships and training that counts toward classroom credits, to gain future employees.

Gonce identifies 17 aircraft customer programs currently in production, with parts ranging from longitudinal beams for engine cowls, to fairings and covers, to interior parts. Airbus commercial, Airbus Defense & Space, and Sevilla-based Alestis are the primary customers. All parts are hand laid, and 95% of them are cored sandwich construction, while 5% are monolithic (uncored). Although manufacture of layup tooling is currently outsourced to several tooling subcontractors, Jerez has begun producing its own trim tools (more on that, below). Likewise, honeycomb core shaping is outsourced, but plant manager Rosario Lopez says Jerez is starting to do some shaping internally.

The tour starts in the facility’s lean manufacturing meeting area within the large, open, busy building. Here — and, at each Carbures facility — a stand-up meeting is held each morning, next to wall-mounted manufacturing charts, in accord with lean manufacturing procedures. The goal is transparency across the workforce while ensuring implementation of quality procedures. Carbures Jerez holds numerous quality certifications — Nadcap in composites and ultrasonic inspection, ISO9001, ISO14001 — and process certifications from Airbus and Airbus Military.

After a quick look at the repair workshop, where core edge sealing is completed, and at the two freezers used to store Hexcel (Parla, Spain) carbon/epoxy prepreg, Lopez shows off the prep area where molds are cleaned and mold release is applied before transfer into an adjacent cleanroom for layup. Here, more than 20 multi-person teams execute well-choreographed part layup processes, quickly laying up kitted plies previously cut on a CNC flatbed cutter from Zünd Systemtechnik AG (Altstätten, Switzerland). Lopez points out that each cut ply is identity-stamped before kitting, just one element that ensures the traceability that is typical in aerospace production for each part.

When layups are ready, prepped and bagged (bagging materials are supplied by Airtech International Inc., Huntington Beach, CA, US), tools are wheeled to the staging area in front of a 12m by 4m autoclave, supplied by Olmar (Gijon, Spain). A smaller, (1.6m by 1.4m) autoclave also is available. “We are currently working two shifts, but can staff up as needed to keep up with peaks,” says Lopez. (Some work — particularly, the monolithic carbon/epoxy curved structural beams — is moving to Technobahia for processing in that building’s 7m by 3m Olmar autoclave.)

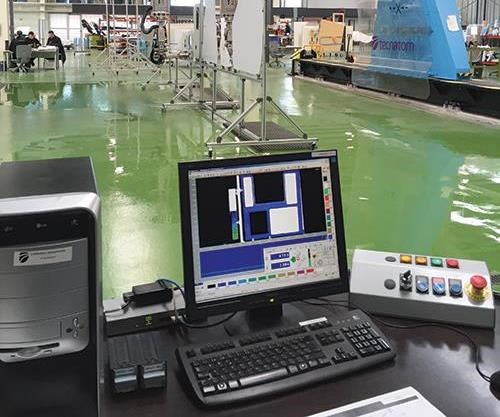

From the autoclave, cured parts travel to an automated C-scan nondestructive testing (NDT) gantry supplied by Tecnatom SA (San Sebastian de Los Reyes, Spain). Here, says Gonce, 100% of the plant’s production is checked. To verify the C-scan results, selected parts undergo additional pulse-echo A-scan inspection: technicians use handheld scanners from Olympus (Waltham, MA, US). Lopez says that for selected Airbus A350 parts, new statistical methods have reduced the C-scan load, but periodic destructive tests are required in those cases. Lopez explains that for some parts, C-Scan has been removed, and for others, it has been reduced to one part in five. But if parts don’t pass destructive tests? C-Scans of every part are back in force. “If, in any case, the testing goes wrong,” she notes, “you have to retest all from the beginning, until you have, again, five consecutive [destructive] tests with good results.”

After testing, parts undergo required finishing. In some cases, that means application of a Tedlar film or, for cored parts, edge sealing. When painting is necessary, that is currently performed by a subcontractor, but an in-house paint shop is planned, says Lopez.

Also currently outsourced but coming in, is part trimming. A newly installed EPMM 25 CNC machining center (European Portal Milling Machine, Seville, Spain) is still undergoing testing but will be in use later this year. Lopez shows CW trim tool prototypes that Carbures will produce from Necuron epoxy tooling board (Neucumer GmbH, Bohmte, Germany) to assist with trimming.

Finally, parts undergo a metrology check, for which technicians use a laser tracker from FARO Technologies (Lake Mary, FL, US).

“Carbures Jerez has experienced an aggressive ramp-up rate for production,” says Lopez. “We’re currently at Rate 6 [six shipsets per month] for Airbus components, or about 60% of our capacity.” Gonce adds that although the Airbus A320 has fewer composite components than other craft, it has the more demanding production rate, and the plant will be close to 100% capacity in 2017. When queried about the potential for robotics at the plant, Lopez says that automated layup has been considered, but right now, “it’s difficult to make the numbers work. We’re not there yet. But we foresee resin transfer molding [RTM] as a potential.”

That approach would fit with Carbures’ Rapid Multi-injection Compression Process (RMCP), an automated process under construction at the company’s Mobility facility (more on RMCP below). Out-of-autoclave (OOA) processing of thermoplastics is another possibility, given testing currently ongoing at Airbus and Tier 1 customer Stelia (Toulouse, France).

Illescas — part of the Airbus aerospace cluster

The Carbures Illescas plant, located in the southern outskirts of Madrid, is just down the street from the Airbus wing assembly plant CW visited in 2012 (read more located under "Editor's Picks" on the top right). There, CW is met by Arturo Pastor, Carbures’ quality director for the Aerospace and Defense business (including China), and Isabel Plazas, Illescas’ manufacturing engineering director. Previously operated as Composystem (where Jerez’s Lopez was employed), it was acquired by Carbures in November 2013. Pastor explains that the 8,600m2 facility, with its roughly 100 employees, has a longer history than the Jerez facilities. “We have a longer chain of benchmarks and quality improvements at this location,” says Pastor, who adds that Carbures Illescas is an award-winning Airbus supplier.

Here, Pastor reiterates the importance of worker team communication and expands on Carbures’ lean manufacturing and quality initiatives: “We’ve implemented a program called SQCDP (Safety, Quality, Cost, Delivery and People), which is in the process of being implemented company wide, to meet key metrics, especially on-time part delivery.” As one example, communications from Stelia or Airbus, whether negative or positive, are posted on the lean meeting area wall; when a complaint has been rectified, that action is communicated as well, to close the loop. “We’re now going to add a new letter to SQCDP,” he adds: “‘F’ for foreign object detection, and implement FOD elimination procedures that will further reduce our already-low scrap rate.” The Illescas plant also has all of the previously described, aerospace-required ISO and Nadcap qualifications.

Although the building is almost 20 years old and, unlike Jerez, not designed with workflow in mind, its processes nevertheless have been optimized to maximize output of mostly small, mono-lithic carbon/epoxy parts made via hand layup for the Airbus A380. Additional parts for the A350 program are produced for Stelia. One obvious non-carbon part is a complex-shaped, cored fiberglass dorsal fin fairing for the A380, the only fiberglass part produced at the plant.

In front of the recently redesigned freezer, Pastor explains the “quality reception” process, in which small samples of incoming Hexcel prepreg batches are collected and tested. In the cleanroom nearby, Plazas points out the “experience matrix,” a wall chart that lists every layup technician and each one’s length of service. This enables assembly of layup teams in which less-experienced workers are grouped with an expert. Layup kits are assembled from plies cut on a Gerber Technology (Tolland, CT, US) automated flatbed cutting machine. Says Pastor, “We designed an in-house nesting program for the CNC cutter to ensure minimal prepreg cutting waste.”

When layups are bagged and prepped for cure, Plazas explains that Carbures’ batch-cure strategies maximize the space within each autoclave and take advantage of their known heat circulation characteristics. The larger, US-manufactured autoclave, at 15m by 3m, can accommodate two tiers of parts and, she explains, years of experience have shown which parts should be placed on the upper or lower level, and how far from the door. A smaller, 3.5m by 1.5m autoclave from Olmar is used in tandem with the larger vessel.

As is the case at Jerez, parts undergo post-cure NDT, using a Technatom C-scan unit, are spot checked with handheld pulse-echo A-scan instruments and then undergo dimensional scans with a Faro arm or, for older program parts (A380, A320), are placed in calibration tools and jigs.

Directly across from the NDT area is an enclosed quality laboratory that houses an Instron (Norwood, MA, US) test frame and a dynamic mechanical analysis (DMA) tester from TA instruments Inc (New Castle, DE, US). In addition, Pastor notes that two new machines will be operational by CW press time: a differential scanning calorimeter (DSC) from Mettler Toledo Inc. (Broomfield, CO, US) and a tensile and compression tester from Zwick Roell Group (Ulm, Germany), to enhance the lab’s testing abilities.

CNC trimming and drilling of cured composite parts also is outsourced, but Pastor says the process will be brought in-house soon, before year’s end. Some manual finishing tasks are completed in a small workshop annex.

Employees are working two shifts on layup, and the autoclaves run three shifts, five days a week. Pastor and Plazas say Illescas is at about 50% capacity now, but Airbus is ramping up production. Says Pastor, “Our client’s build rate is becoming more intense.”

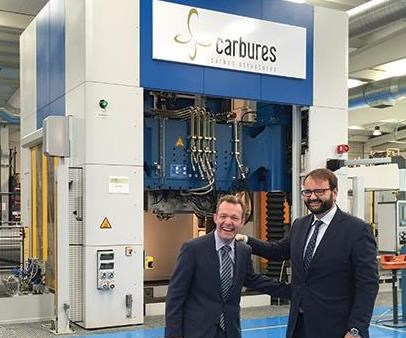

El Burgo de Osma — Mobility and automation

The Mobility facility is in El Burgo de Osma, a small town steeped in history several hours north of Madrid. There, CW meets Carbures’ managing director Roberto Rey and Mobility’s general manager, Josef Neuhäusler. The latter founded the automotive system design firm aXcep (Munich, Germany), which was acquired by Carbures and combined with MAPRO, an automated assembly line/ machinery firm, and Technical Racing Composites (both of Barcelona, Spain) to form Mobility in 2014.

Mobility’s sales soared from €3.3 million (US$2.9 million) at its inception to €39 million (US$44 million) in 2015, thanks to Neuhäusler’s and MAPRO’s deep auto industry roots. A big part of that growth is due, he says, to 2014 contracts with Shenyang Hengrui (Harbin, China) that involve commercialization of assembly lines for autocomposite parts.

The 2,600m2 facility was built in 2014. Fabian Patus, Mobility’s quality and operations director, and Mariangeles Gonzalo Vallejo, plant coordinator, lead the tour, starting with its SQCDP quality area. Here, we’re told, additional metrics are employed for automotive manufacturing, including OEE (overall equipment efficiency) and the system known as “5S,” a workplace organization system originally based on Japanese lean process development. “It means ‘one place for everything, and everything in its place,’ which has really helped our productivity,” says Gonzalo. “We will also start to implement Six Sigma methods in the near future, to ensure stability of our processes.” The facility anticipates obtaining ISO TS16949, a quality management certification for the application of ISO 9001 to automotive production, by November of this year. IRIS, the International Railway Industry Standard, should be in place by July 1, adds Patus.

Our next stop is an area of the shop floor dedicated to an assembly project for automotive supplier Huf (Velbert, Germany). Further on, Patus shows two projects for rail customer CAF (Construcciones y Auxiliar de Ferrocarriles, Beasain, Spain) involving assembly of mechanically activated emergency exit ramps for underground subway and above-ground trains. Although these projects don’t currently involve composites, Mobility’s chief design engineer Manuel Andrés Rey says Carbures in El Burgo de Osma is working with CAF to convert metal elements of the exit ramps to composites, using a light RTM process.

The facility’s centerpiece, however, is an automated workcell that is a forerunner of the coming Rapid Multi-injection Compression Process (RMCP), an automated, injection-based workcell developed and patented by Carbures. The RCMP is expected to be a primary means to fulfill its Shenyang Hengrui contracts. RCMP details are proprietary, but the current workcell operates as a high- pressure RTM (HP-RTM) system for making complex structural parts, explains Patus. “The cell is equipped with a single resin injection port, and is making parts right now.” He points out an adjacent area, under construction, where an RMCP line will be located, noting that it will employ multiple injection points, enabling mold fill in seconds, using relatively low injection pressure, which will, in turn, allow the use of a smaller-tonnage press. When complete, the new RMCP line will look similar to the existing automated cell, but, Neuhäusler contends, “With a cycle time of 3-6 minutes, one RMCP line, running 24/7/365, will produce up to 150,000 parts per year.” Patus explains that a building expansion over the next 18 months will make room for more RMCP lines and a new testing laboratory.

“We anticipate that we’ll have four part-production lines by 2020 in Burgo de Osma,” asserts Neuhäusler.

The existing RTM workcell takes automatically cut plies of carbon non-crimp fabric from an automated cutting table. The plies are robotically placed in a heated tool on the press shuttle, using a needle gripper-equipped end-effector. The tool is shuttled into position in the open press, vacuum is applied and the press closes the tool as epoxy resin, which includes an internal mold release, is heated by the delivery system before being injected together with hardener. Injection takes about 15 seconds. After a press cycle of about 4-5 minutes, the press releases and the tool is shuttled out for robotic part retrieval. The large needle gripper can handle a wide range of cut fabric sizes. And, in contrast to many workcells, the press’s operating machinery is located in a pit beneath the cell, saving considerable floor space.

Neuhäusler says the part demonstrated for CW is a test for automotive wheel rims, part of a composite wheel program in collaboration with 2elle-engineering (Trebaseleghe, Italy) for unnamed sports car models. Wheels will be all-composite, or have a carbon/epoxy rim with aluminum hub and spokes — a better design in his opinion: “There has never been a homologated carbon wheel yet, because it’s impossible to detect damage.” Carbures is exploring the use of braided preforms for the wheel application, with braid supplied by Munich Composites GmbH (Ottobrunn, Germany). Other customers, he says, could include huge Tier 1 Faurecia (Nanterre, France), for auto seats.

Growth and expansion

So what’s the takeaway from seeing this Tier 2 in action? Despite the sleep deprivation caused by the torrid pace of work at all three facilities, everyone CW met seemed up to the challenge of growing a Spain-based, global composites company. Indeed, the future looks bright: 2015 was the company’s best year ever in terms of total parts and revenue for the Aerospace business — 39,322 parts and €16.6 million (US$18.75 million). The company also, in 2015, formalized a loan from Black Toro Capital (Barcelona, Spain) for expansion, and added Domingo Ureña, former chairman of Airbus Spain, to its executive committee. Under the leadership of Rafael Contreras, president and co-founder, and Roberto Rey, CEO, Carbures has a strong business plan geared for continued growth.

Related Content

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More