Clear Carbon & Components: Bristol, RI, US

Breaking barriers in process and complexity, this agile manufacturer is gaining renown as a composites problem solver and champion of Class A cosmetic surfaces.

Many CW readers are already familiar with the aesthetics achieved on parts produced by Clear Carbon & Components (C3, Bristol, RI, US), having seen them as showpieces in exhibitors’ displays — A&P Technology Inc. (Cincinnati, OH, US), for one — at composites tradeshows. C3 also is the manufacturer behind the stunning carbon fiber-reinforced plastic (CFRP) bodies for the composite violins, violas, cellos and bass viols marketed by Luis & Clark Stringed Instruments (Milton, MA, US), highlighted in a 2012 CW feature article (see Fig. 1, at left, and read more in "Acoustical architecture: Making beautiful music," under Editor's Picks at top right). A leader in the composites-intensive US state of Rhode Island, C3 president Matt Dunham was one of the founding members of the Composites Alliance of Rhode Island and continues to serve on its steering committee (Read more online about the Composites Alliance of Rhode Island here and here.

Dunham was a metal worker, making America’s Cup 12m racing sailboats out of aluminum, when that industry switched to CFRP in the late 1980s. Dunham followed, establishing C3 in the early 1990s, but then quickly focused on diversification.

Today? “There is no industry that we don’t touch,” Dunham remarks, listing an impressive range of other finished products to support his point:

- Unmanned aerial vehicles (UAVs) and parts for the aerospace industry

- Parts for motorcycles and other transportation industry applications

- Antennae, electronics enclosures and more, for military ground forces

- Sonar enclosures and communication buoys for naval operations

- CFRP vertical-axis wind turbine (VAWT) and other renewable energy projects

- CT scanner head support and other medical products

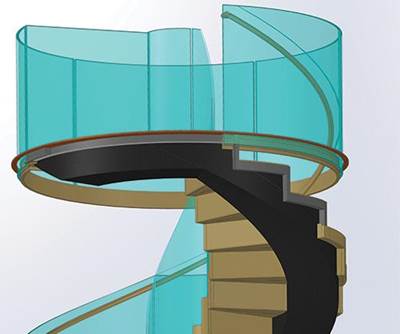

- Architectural components, including a 4m-tall spiral staircase with a one-piece CFRP spar (read about this project in CW's Inside Manufacturing story, titled "Structural work of art," under "Editor's Picks" at top right.)

Further, C3 is active in numerous R&D programs. “We do a lot of R&D,” says Dunham, “but it’s all aimed at getting one more part into production.” Schooled in America’s Cup excellence, yet faced with the realities of operating a small business, he explains a requisite balance: “I believe you have to have both serial production and R&D. The R&D is important to develop new technology and new business leads, but you can’t sustain a company that way. You must have the everyday, bread-and-butter production.” Dunham says the two are treated as separate business segments, adding, “If one-off projects like the spiral staircase were all that we targeted, we’d never get the production jobs we need to stay healthy and diversified.” C3 and its staff of 20 seeks both in its 1,400m2 facility in Bristol, purchased in 2010 after a move there five years earlier. C3 makes its wide variety of composite components using wet and prepreg layup, vacuum infusion and compression molding. Dunham’s recent invitation for CW to take a walk through the C3 operation revealed evidence of an organized yet out-of-the-box mentality that makes clear how this small company has reached so far into the markets that composites serve.

Development-refined production

CW’s tour begins in the front office suite and CAD room, where engineers design not just parts, but the plugs/patterns and molds necessary to produce them, using SolidWorks (Dassault Systèmes SolidWorks Corp., Waltham, MA, US), Rhino3D (Robert McNeel & Associates, Seattle, WA, US) and Mastercam (CNC Software Inc., Tolland, CT, US). “It’s really important to do your homework in the digital modeling,” says Dunham. “Walking through the potential construction issues can make the difference between profit and loss on the type of high-performance and high-aesthetics projects we do.”

When asked about the company’s reputation for “clear carbon” parts, where the high-gloss surface shows the fabric weave without skew, wrinkle or other imperfection, Dunham explains that understanding the materials and various molding processes has been the key. “We get better surface finish with infused laminates vs. hand layup because of the lower void content,” he asserts, adding, “the print issues must be addressed, however.”

Print, or print-through — when the texture of the laminate can be seen through the part’s paint or topcoat — is a key quality issue. “For example, we want to fill in the interstices between the fibers in a fabric weave, because, over time, these will show pock marks,” says Dunham. He notes it is also important to avoid pinholes in the finished laminate.

Dunham opens the door into C3’s large production space (Fig. 2) and turns right to walk through the serial production area, referred to as the production work cell, where racks of assem- bled parts await finishing and inspection. Across from the racks, workstations are organized for efficient assembly of products (Fig. 3). “We’ve developed how to do cost-effective serial manufacturing, with over a dozen products running through our production workcell at any given time,” says Dunham.

One example of C3’s high-quality, serial production is ladders for docking yachts, produced for Bristol Yacht Components (Essex, CT, US). The yachts move up and down relative to the dock, so the stairs must articulate. Dunham explains, “After about nine stairs, you have to turn the step sideways or the disembarking passenger would end up off the other side of the dock into the water.” These ladders comprise CFRP treads, rails, a regulator (which keeps the stairs parallel and level) and a slewing platform. This 0.9m wide circular platform has a pivot mechanism that enables the ladder to rotate and cascade out in different directions. The CFRP components make the ladders lightweight and unique.

This highlights one of C3’s strengths: building relationships with customers. “We focus on more high-end applications,” notes Dunham, “but then we drive cost down in serial production.” The company also specializes in one-off applications that have hit obstacles in manufacturing. “We figure out how to make the parts,” says Dunham. “A lot of what we do is developing new processes to make composites production possible.” Not just possible, but high performing and high quality, cosmetically.

The company also has strong relationships with key suppliers, including advanced materials suppliers Core Composites and Gurit (USA) Inc., both based in Bristol, and 3D textile weaver T.E.A.M. Inc., located less than an hour away in Woonsocket, RI. Dunham shows a large “brick” of 3D woven carbon fiber. “We’ve worked with T.E.A.M. to make carbon-reinforced carbon [carbon/ carbon] composites using a compression infusion process,” he relates. The materials are being used to mold complex-shaped military components.

Compression molding capability

The last stop in the production workcell area is a tour of two compression molding presses supplied by Wabash MPI (Wabash, IN, US). The larger, 150-ton vacuum press — i.e., maintains vacuum while pressing parts — is heated and cooled, and capable of processing at 430°C. “It helps to maintain low void content, pulling volatiles outgassing from the part if you need it,” explains Dunham. The smaller, 75-ton press can go up to 315°C. Dunham describes how charges are prepared for press molding using techniques borrowed from the garment industry, such as die cutting, which produces multiple laminate plies quickly and cheaply.

“We developed compression molding for making ‘widgets’ to join parts,” Dunham explains, “for example, a CFRP weldment used for transition to bond a stanchion onto a rail. Because this weldment has a Class-A surface on both sides, I can now very precisely control my bondline spacing, which is key for long-term bond performance.” The CFRP rail Dunham shows is hollow with a formable core and bent, tapered ends (shown as part of Fig. 1, at left). C3 also compression molds the lightweight, watertight hollow CFRP body parts for the SeaHex marine-duty tri-copter UAV.

Dunham shows several other aerospace parts, in this case, compression molded from Quantum Technologies (Bay City, MI, US) carbon fiber sheet molding compound (SMC). “It provides two Class-A surfaces,” says Dunham of the material and process combination, “as well as very high tolerances, for example, molded-in circular cutouts within 0.025 mm.” The finished parts also can be drilled without having to reinforce the perimeters of the holes with metal. Combine this with compression molded CFRP’s lightweight, strength and unique aesthetics, and it becomes an appealing alternative for applications such as motorcycles.

Indeed, C3 helped Walt Siegl Motorcycles (Harrisville, NH, US) adapt the process for a custom MV Agusta Brutale 800, a one-off signature bike to help artist/designer David Yurman celebrate his new line of carbon composite accessories (Fig. 4). The David Yurman Forged Carbon Moto features a front fender, a rear hugger, a triple tree and brackets made from a CF molding compound that Lamborghini (Sant’Agata Bolognese, Italy) and Callaway Golf (Carlsbad, CA, US) partnered to develop and market as Forged Composite. Dunham continues, “We also can make a part every 15 minutes and are playing with thermoplastic compounds for even lower cycle times.” He notes that with thermoplastics, in particular, the process is more about how to handle cooling rather than heating. “We have also developed a method for making CFRP coiled springs (Fig. 1), what we call contoured composite tubing,” says Dunham. “We use a very low-cost mold for making these coiled springs, which come out of the mold with this high finish quality. None are post-finished.”

Equipped for agile manufacturing

Adjacent to the production workcell is an enclosed trim room. The built-in dust collection system within includes down- draft evacuation and a HEPA filter. The trim room walls are soundproof to insulate the rest of the facility from the noise. Similar to the production workcell stations, trim-room tools are organized for easy access, a result of C3’s focus on lean manufacturing.

Past the trim room is an enclosed CNC machining room. “This has become a big part of our business,” says Dunham. “We can take a CAD file from anywhere in the world and go directly to a mold. The days of making patterns are over.”

C3’s CNC machining operation also has eliminated the need for C3’s carpentry shop operations, making that space available now for small-parts production.

On the way to the opposite side of the open production space, Dunham points out a dedicated resin mixing station. “We use all neat resins that we promote and mix ourselves, because we must know exactly what the resin gel times are for processing,” he explains.

Passing by a 4m by 8m paint booth, no less a point of potential C3 innovation (Fig. 5), he arrives at a substantial machine shop, which, Dunham explains, “allows us to make our own jigs, fixtures and tooling, so we aren’t dependent on anyone else’s lead times to begin production.”

The result is agility that enables innovation, exemplified by the composite ISO military shelter C3 is assembling during CW’s visit. Typically, 2.4m wide by 6m long, these lightweight, rigid-walled enclosures are intended for quick deployment via transport aircraft or helicopters, for use as emergency housing, medical facilities and to protect electronics and other mission-critical equipment. Their cored-panel construction provides thermal insulation, resists weather, meets fire standards and can withstand significant handling abuse. The shelters C3 is helping to develop are basically composite containers that fold out into 7.3m by 7.3m field hospitals.

Although the current ISO shelter design is only certified to ship six shelters high, C3 designed a new, hollow CFRP corner post, machining the aluminum tool for it in-house. The hollow composite post is laid up in the aluminum tool with an expanding mandrel, which provides compaction during cure and contracts upon cooling for easier demolding. The new post can withstand 95,708 kg and, therefore, will allow shipping of shelters stacked nine high on new super-container ships.

Infusion as an enabler

The center of C3’s production space is occupied by a 2.7m by 6m carbon composite table (Fig. 6) heated from below to provide the same coefficient of thermal expansion (CTE) as the parts it is used to infuse. Resin infusion has become a core competency for the company, highlighted in many projects. One of note involved all-carbon fiber/epoxy, hollow (uncored) hat sections molded in segments more than 18m long for the 30.5m sea racer Comanche, owned by famed billionaire/sailing enthusiast Jim Clark (Fig. 2). The all-carbon racing yacht smashed the transatlantic monohull record, completing the 2,880 nautical miles on July 28, 2016, at an average speed of 21.44 knots!

“The challenge was to infuse the carbon unidirectionals,” Dunham recalls. “We do a lot of infusion. I’ve got people who have been doing infusion for 20 years. We have developed a lot of tricks for how to get the resin to move where we want it, without dry spots and foaming, which is key both for low voids and long-term aesthetics.”

One of C3’s recent advances is infusing phenolic resin. “It’s all about controlling the cure,” Dunham explains. “You have to know what the temperature is at all times and how to ramp it to control the condensation reaction of the phenolic resin. Because it actually produces water as it cures, you have to control the cure to avoid this.”

Also used for the ISO military shelters, the infused phenolic panels help meet fire resistance requirements (Fig. 7). But Dunham’s team has gone a step further, developing a method to infuse panels with two finished sides and molded-in edge treatments. “Edge treatment is typically the Achilles heel of a composite panel system like this,” Dunham notes, “and also for architectural applications. We have figured out how to do very sophisticated edge treatments to meet customer needs.” He describes a tooling system that delivers edge features when molding so that no post-finishing or machining is required.

For the military shelters, it’s not just the edges where the panels are attached to form the enclosure, there are also “knock-outs” — that is, areas that are easily removed to install HVAC systems. Dunham says the edge closure for these areas used to require a 50-piece system of metal frames and fasteners. “We have eliminated that through our molded-in geometry and local reinforcements,” he says.

The shelter floor also is a study in unitization, molded in one piece with integrated stringers. Where attachments are needed in the floors and walls, hard points have been molded-in using fiber-reinforced, high-density polyurethane foam (e.g., foam board from Coosa Composites, Pelham, AL, US). There is no secondary machining, just installation of fasteners for overall shelter assembly.

The shelter’s infused panels also are improved by C3’s longtime partnership with A&P Technologies, using the latter’s QISO material to optimize impact resistance. “QISO was originally developed for the braided containment ring used in GE90 engines for the 777 aircraft,” says Dunham. “The fibers in the braid go up and over each unidirectional, encapsulating it and preventing delamination.” Dunham says this is indeed the next generation of military shelters, and C3 is making both 6m and 3m long versions.

Skunkworks for composites companies

The final stop on the tour reveals a significant space currently devoted to an unusual program done under a nondisclosure agreement, one which has just entered production.

“This project was actually brought to us by another composites company,” says Dunham. It was big, unprecedented, complicated and, well ... no one else wanted to do it. And it’s not the first time. “We’re kind of the ‘skunkworks’ for other companies in the composites industry,” he quips. “They come to us to help them figure out how to make stuff.”

Indeed, since CW’s tour, C3’s full-scale parts for the proprietary effort have passed field tests, and C3 has completed large-scale tooling, doing one of the things it does best, overcoming significant challenges in geometric complexity.

But doing the unusual isn’t that unusual for this big little shop in Bristol: From violins to fold-out medical units, yachts to UAVs, if it’s CFRP, C3 makes it quickly, delivering high performance and high quality, and if required, with C3’s renowned clear carbon finish, no matter the difficulty.

Related Content

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreVIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MoreCompPair adds swift prepreg line to HealTech Standard product family

The HealTech Standard product family from CompPair has been expanded with the addition of CS02, a swift prepreg line.

Read MoreRead Next

Structural work of art

Composites fabricator uses an innovative molding approach and digital techniques to actualize architect’s customized residential stairway.

Read MoreAcoustical architecture: Making beautiful music

On the market for more than 40 years, composite musical instruments have advanced from a novelty to critical acclaim.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=150;quality=70)

.jpg;maxWidth=400;quality=70)