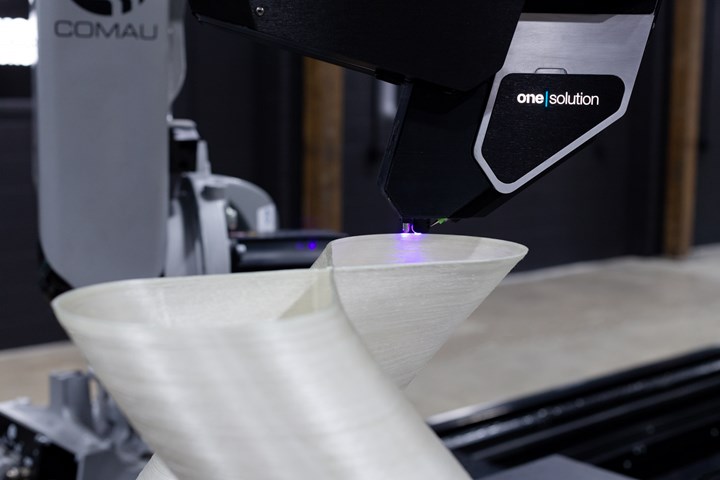

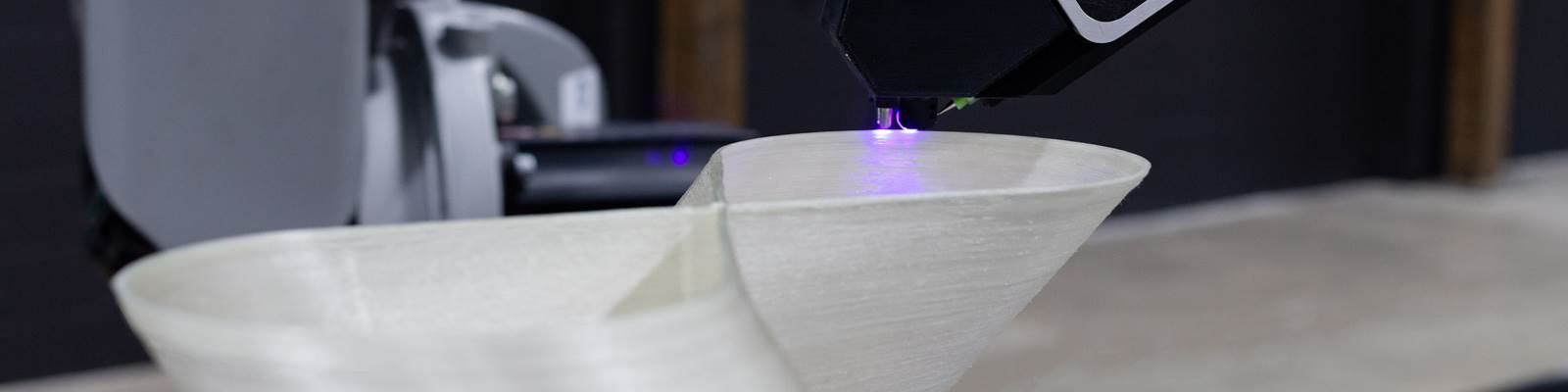

CF3D technology uses snap-curing thermoset materials to reduce high cost, long lead times and design constraints. Photo Credit: Continuous Composites

In September 2020, continuous fiber 3D printing specialist Continuous Composites (Coeur d’Alene, Idaho, U.S.) announced a strategic partnership with specialty materials company Arkema (Colombes, France) through its Sartomer business line, to combine Continuous Composites’ patented Continuous Fiber 3D (CF3D) printing technology with Arkema’s photocurable N3xtDimension resin solutions. The combination is expected to result in development, certification and commercialization of a library of advanced material solutions to suit the needs of a wide variety of applications and industries.

This formal partnership has grown out of a relationship that first began in 2015, when Dr. Sumeet Jain, senior director of 3D printing at Arkema Worldwide, became aware of Continuous Composites and saw an opportunity in the printing process the company was developing. According to Tyler Alvarado, CEO of Continuous Composites, the partnership was natural: “He [Jain] saw the opportunity to advance photocurable thermoset resins, and we saw that he had decades of experience with the polymers we were using.”

By 2019, the companies had a joint development agreement, and at the beginning of 2020, Arkema took an equity position with Continuous Composites, with the strategic partnership announced in September. “We are extremely excited about the partnership and the results that both teams have been able to achieve. It’s one of those things where one plus one equals three, really leveraging their experience not only in the composites space but in photocurable thermosets,” Alvarado says.

Bridging photocurable resins with continuous fiber 3D printing

Today, Arkema’s Advanced Materials segment has branches spanning many materials, including thermosets and thermoplastics, and, within composites, many processes and applications, including 3D printing as well as more traditional manufacturing processes. The Sartomer business line focuses on specialty acrylates and methacrylates for a range of markets, and has been providing UV-curable materials in the forms of coatings, adhesives and 3D printing filaments for decades, according to Jeffrey Klang, Sartomer R&D director for the global 3D printing team.

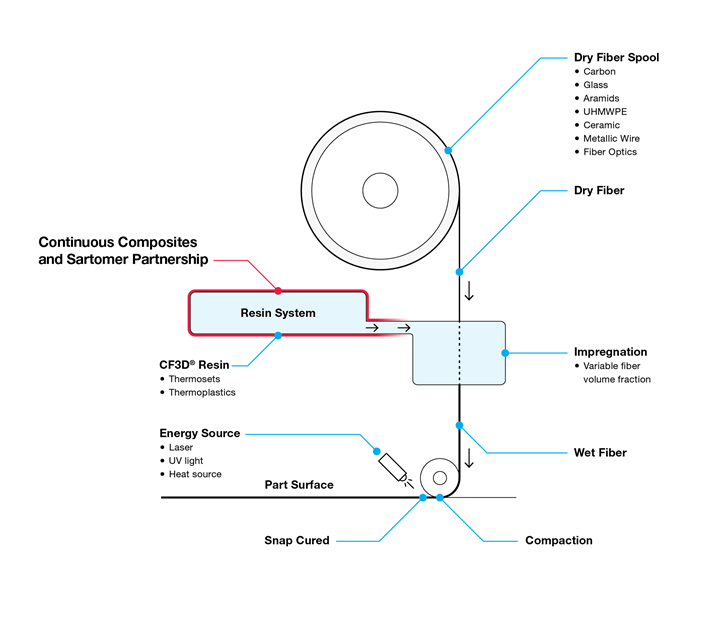

To complement its CF3D printing system, which is an out-of-autoclave (OOA), scalable 3D printing technology based on the use of snap-cure resins and continuous fibers (read a more detailed description here: “3D printing composites with continuous fiber”), Continuous Composites required a catalog of resins that met the high-performance mechanical requirements of customers in industries ranging from aerospace to energy to defense. “Our business model is to provide machines, and their corresponding software and resins, to enable these customers to manufacture whatever component they’re going after in their specific industry application,” Alvarado says.

The CF3D print process in combination with Arkema’s N3xtDimension resins. Photo Credit: Continuous Composites

This need for high mechanical properties such as glass transition temperatures (Tg) and fire, smoke and toxicity (FST) led to a focus on thermoset resins, though Alvarado notes that CF3D technology can use thermoplastics as well. “Our core competency is that we are taking a dry, continuous fiber, and then we’re impregnating that with a snap-curing — in this case, UV-curable — resin,” he says. “We’re really focused on this snap-curing thermoset approach that allows the composite structure to take shape right there in freeform, enabling us to leverage the anisotropic properties of the continuous fiber, and create these complex organic geometries that are extremely lightweight and very strong. We can produce a very high-quality composite laminate with very high fiber content and low porosity.”

Sartomer’s N3xtDimension liquid resins, part of Arkema’s newly launched 3D Printing Solutions by Arkema platform, in combination with structural fibers ranging from carbon and glass fiber to Dyneema and aramids, proved an ideal match, and the companies are now working to develop a library of UV-curable resins meeting a range of mechanical property requirements.

In addition to the resins’ mechanical properties, eliminating the need for heat cure on the final parts enables two of CF3D’s most innovative features: fast print speeds, and the ability to print unsupported in open air. “Normally, when you’re laying up a composite, you’ve got to have tooling/molds to support the layup,” Alvarado says, “but because we’re using snap-curing thermosets that are reinforced by a structural filament, we’re able to harden that material and it can take its shape without that support material.” This eliminates the cost and lead time involved in acquiring molds and tooling, and removes the design constraint of having to design around tooling. “Now you can steer these fibers in many directions … Having the ability to print unsupported allows really unique overhang geometries to span large gaps,” he says.

Further, CF3D “is a very stable machine ... and prints significantly faster than traditional thermoplastic machines,” Alvarado says. These speeds are made possible by the elimination of problems such as managing temperature gradients within the laminate and warpage (due to the use of thermosets over thermoplastics), and that the system isn’t limited by a heating process (due to its use of UV light cure).

Continuous Composites’ CF3D process prints ultra-high-molecular-weight polyethylene in a twisted figure 8 geometry. Photo Credit: Continuous Composites

There are two variables to print speed, he adds: material cure and print accuracy. “The problem is not the resins; they cure in time. The machine is the bottleneck,” he says, noting that robots as a motion platform were originally designed for repeated, point A to point B pick-and-place movement but not necessarily for the accuracy involved in 3D printing. “Our team has actually developed our own integration of a CNC controller as the underlying motion platform control for our 3D printing system, so that we can move through points accurately and repeatedly, which allows us to drastically increase the speed at which we’re printing right now,” he says. Using the CNC controller, over the next year, Continuous Composites plans to increase the system’s print speed up to three times.

As with any innovation, though, there have been challenges associated with transferring Sartomer’s UV-curable resin technology to higher-performance and structural applications, according to Sartomer’s Klang. For example, one area of focus has been increasing temperature resistance. “We’re at close to 230°C,” he notes, “which really gets us in some very interesting new types of applications.”

Arkema’s Jain adds: “With this partnership, we are working from the bottom up, to change the way that composites are manufactured. This is not trivial. We’ve been working together for four years already, and we’re just getting started.”

Related Content

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

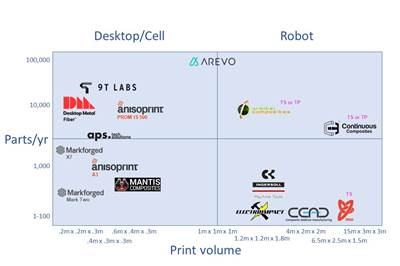

Moving continuous-fiber 3D printing into production

With patents proliferating and production applications emerging, 3D printing with continuous fiber reinforcement is poised for significant market growth.

Read More3D printing with continuous fiber: A landscape

Growth continues in suppliers, part size, production volume and markets.

Read MoreContinuous Composites, Arkema partner to advance continuous-fiber 3D printing

The companies will combine Continuous Composites' CF3D process with Arkema's photocurable resins to develop and certify composite 3D-printing solutions.

Read More

.jpg;width=70;height=70;mode=crop)