Composites 4.0: Where to start?

Sensors, IoT platforms, data analytics — the tools for more intelligent, efficient manufacturing abound, but where to start is actually much simpler.

This is an online sidebar for the July 2020 article, “Composites 4.0: Digital transformation, adaptive production, new paradigms”. In that article, I define Composites 4.0 and then discuss various applications and implications. Here, I want to set out why you should care and then walk through some practical advice from two companies who have experience in how to begin.

Composites 4.0: Why it matters

Already the change has started. Companies are using digital technologies, sensors, data analytics and artificial intelligence to improve quality, reduce cost, boost production rates and cut lead times. Within the next 10 years, suppliers who can’t match these metrics will find it increasingly difficult to compete.

But surely it doesn’t apply to everybody? The examples I discussed in the main article ranged from filament winding to resin infusion, automotive to aerospace and industrial, carbon and glass fiber, thermosets and thermoplastics.

At last year’s Carbon Fiber 2019 conference, I led a panel discussion on Composites 4.0. Here are the summarized pros and cons from the panelists:

“Companies are realizing they need to begin the digital transformation journey, but where to start?”

Start with the data you have

“We’re seeing growing business activity and more composites companies involved with edge-computing, cloud-computing, AI [Artificial Intelligence] and 5G communications,” says Avner Ben-Bassat, president of Plataine (Waltham, Mass., U.S. and Tel Aviv, Israel), a supplier of Industry 4.0 software for composites manufacturing. He notes that as a company, Plataine sees roughly 200 factories per year. “A few years ago, we would have had to explain edge-computing and AI. Now, our discussions are more elevated. All of this activity is serving cost reduction and production increase with the goal of faster, better, cheaper.”

With this increased activity, however, there also comes a plethora of opinions. “Everybody now is talking about the data and you have to have 5G to collect the data,” says Ben-Bassat. “But there is already so much data being collected that companies are not using. You don’t need 5G or a massive investment to just start with the data you have.”

Many Plataine customers start with Composites 4.0 apps that enable more efficient use of data they are already collecting, such as prepreg out-time, ply kits per part and tool maintenance schedules. Source | Plataine

The real question, he says, “is what do you do with the data? My guidance is to start with your problems first. If you need to increase your rate, where is the bottleneck? What kind of data do you need to collect in order to drive a solution?”

Many companies begin by looking at software and Industry 4.0 platforms, which can be overwhelming. “First, you have to understand your parts, processes and customer demands versus what you can do as an organization,” Ben-Bassat advises. “Then you get to which software and platform might work to achieve the necessary solutions.”

“We have case histories that span the spectrum of composites production, but we also work outside of composites,” he notes. “Some companies have goals, KPIs (key performance indicators) and a ‘digital transformation plan”, which includes elements of change management and training. Plataine then becomes part of that. But we also have companies trying to figure out what to do and where to start. So, we go onsite and do interviews and process analysis. asking ‘what are you trying to do?’ If they’re not sure about that, we assign homework.”

Digital transformation step by step

Though the main article features a compact version of Dynexa’s story, it lacked room for some of the interesting observations and suggestions that I thought were worth sharing.

1. “Many players in the composites industry are not large R&D institutes with millions of dollars to spend on this.”

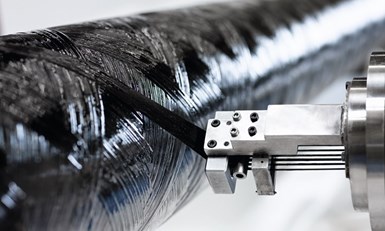

Dynexa uses wet filament winding to produce high-quality carbon fiber composite tubes and shafts. See Dynexa’s CFRP output shaft in “Composite output shaft ready for automotive proving ground”. Source | Dynexa

Christian Koppenberg is managing director of Dynexa (Laudenbach, Germany), which uses wet filament winding to make composite tubes and shafts. “We are a parts producer,” he adds. “So, it is not like we have fancy robots or a lights-out factory. Other producers probably face the same issues that we faced with respect to digital transformation.”

How to make the first step? “We understood not to be overwhelmed by terminology, which we have little knowledge of,” says Koppenberg. “But we do know composites well. Moving toward Composites 4.0 was a little out of our comfort zone, but we understood that everything we put into a protocol or procedure for a worker, this is a code, and this is a kind of basis for digital transformation.”

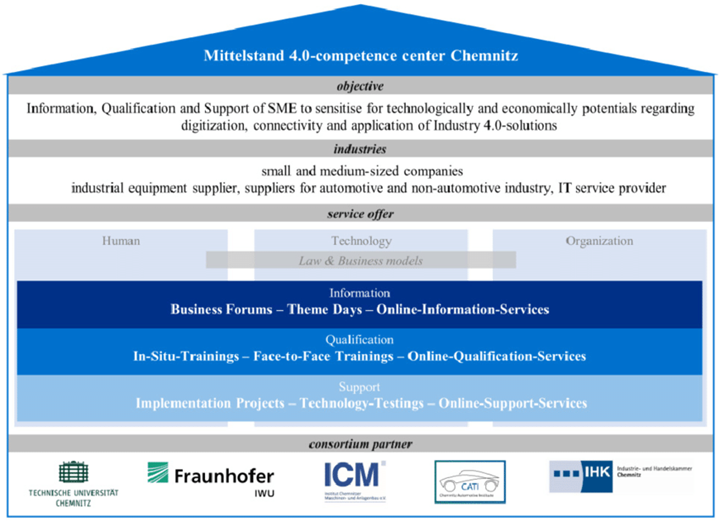

As noted in the main article, the next step was still a struggle. But one thing Dynexa had in its favor was the German government’s commitment to manufacturing. Germany is already a global leader in developing Industry 4.0 standards and technologies. Committed to supporting its small and medium enterprises (SMEs, or Mittelstand), the German Ministry of Economy and Energy (BMWI) funded universities to provide free digitization consultancy to SMEs in their geographical region. Nationwide, 26 Mittelstand 4.0 competence centers provide practical support and cover all topics along the value chain.

Germany’s Mittelstand 4.0 competence centers provide free digitization consultancy to SMEs. Source | Mittelstand 4.0-competence center Chemnitz

“The University of Darmstadt is local to us and was a partner in this government network,” notes Koppenberg. “We began to work with them and found their approach was hands-on and very simple. Their goal was to just help us make the first steps. It was key that they were not trying to sell anything, but instead worked with us to find the right solutions.”

2. “Begin with several key questions: Where is my problem? Where do I need the data? How do I need to measure and communicate that data?”

Dynexa’s first step in its digital transformation was a monitoring system for resin pickup during filament winding. Source | Dynexa

Similar to Plataine’s advice, the University team encouraged Dynexa to ask questions. “Where do we have work that is quality-dependent and worker skill-dependent and costs us money and time? That was our first understanding,” says Koppenberg. “They said not to worry about the architecture — i.e. servers, cloud-computing, edge-computing, etc. That part is straightforward. What we had to decide is what we wanted to do. ‘Don’t overcomplicate it,’ they said. ‘Look more to what you need to measure and how to do that.’ Those decisions would then guide us as to the final architecture.”

As explained in the main article, Dynexa’s start was to develop a digital system to measure how much resin was being picked up and applied with the dry fiber during winding. The previous procedure required the operator to stop the machine, measure the thickness of the tube, log that measurement and then restart the winder. With the University of Darmstadt’s help, Dynexa developed a camera system connected to a database of correction tables and decision algorithms that enables the machine to know what the target should be for each stage of the specific tube or shaft being wound and automatically respond.

3. “This is not about replacing personnel with robots; it’s about changing the process.”

Thus, they were able to transfer manual work into a digital system. “This is not about getting rid of the operator,” notes Koppenberg, “but instead about changing the process. We have achieved better process control, so our production is faster and more efficient. But it’s not about reducing personnel cost. Instead, the operator is still there but now he/she can focus on different things and let the machine handle regulating the resin content. The operator can perhaps look at the next part or oversee more than one machine. This then lets us be more cost-effective and achieve higher quality through all of the machines. That efficiency was our main goal. Before, we had variations in part diameter, and it was one of the main issues we had in production.”

4. Solve the problem and then use the data to further improve the process.

“Another issue,” says Koppenberg, “was how much data is really needed? We could run the camera constantly, but it’s not necessary. We only measure to make the process consistent and reliable for product quality.”

He continues, “Now that we have digitized the process, we can gain experience and further develop it. We have all of the winding machines connected. They are creating data which we can now correlate. Some said, ‘just measure it all of the time and let the AI find the correlations and tell you what to do.’ But this was hard for us to put into action. However, the way we have done it, we can analyze the data offline for correlations to further improve the process, but also to apply this approach to other production processes. We are doing this now,” Koppenberg points out, “which is a digital transformation for us.”

5. True digital transformation will transform not just your production, but your business.

And this transformation continues, through what Dynexa’s head of sales & marketing, Matthias Bruckhoff, calls “a stepwise process of providing a new ecosystem for our customers.” This new ecosystem includes an online portal for customers (see main article: “Changing paradigms”) but also a new digital labeling system that responds to its customers’ requests for all of the part data to be put in one place, including quality control sheets and handling guidelines (see “Digital thread vs. digital twin”).

“I would advise companies that are beginning this journey to consider, 'what keeps me from offering this service or product flexibility to my customer?’ We used to spend so many hours on labelling, now we are not only making our customers more efficient, but us as well. The real value in digitization is if it enables a transformation in the processes behind your business,” says Koppenberg, “and open up new possibilities and maybe, longer term, new business models.”

Related Content

IMDEA introduces digital twin for real-time analysis of composite materials production

Newly designed digital twin by IMDEA and Technical University of Madrid researchers enables manufacturers to see inside composite materials as they are being produced, facilitating early detection of faults.

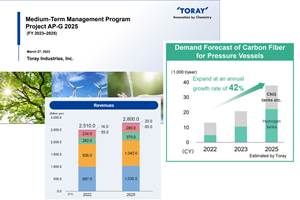

Read MoreToray announces growth, investment in carbon fiber composite materials

As part of its 2023-2025 management strategy, Toray projects 42% growth for pressure vessels, 30% growth in carbon fiber composite materials revenue and a doubling of capital investment.

Read MoreUltra high-rate composite deposition system trials to surpass layup targets

The NCC, alongside partners Loop Technology, Coriolis and Güdel, are on track to deliver dry fiber deposition rates exceeding 350 kilograms/hour, seven times more than standard aerospace rates.

Read MoreModular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More