Composites encourage design creativity in LSA aircraft

Manufacturers of small aircraft expand the private pilot’s options on the strength (-to-weight) and contourability of advanced composites.

It’s been four years since the FAA formalized the rules for a new Light Sport Aircraft (LSA) category, along with a new Sport Pilot license that requires half the instruction and half the solo flight time of a much more expensive Private license. For a lot of aspiring pilots, that’s a big enough difference to make the sale. But something else has made this class of aircraft even more attractive: fuel prices. While a Beech Bonanza burns about 12 gal per hour (GPH) and a Cessna Turbo 310-R burns about 24 GPH, the average LSA, at a maximum gross weight of 1,320 lb/600 kg, burns only 4.5 GPH — a very attractive plus despite the LSA’s lower air speed and fly-time restrictions. In fact, there are now about 50 LSA models in various stages of development from concept to production. Here we’ll look at a handful of the newest machines that have entered the market since the last time we covered the subject (see “Learn More,” at right).

EU Ultralight to U.S. LSA

There’s no shortage of new entries from Europe in general, and Eastern Europe in particular, because planes of LSA size, weight and power ratings were already in production, classed as European Union Ultralights (which differs considerably from the U.S. Ultralight class). As a result, European manufacturers were already well situated to offer existing machines that could be LSA-compliant with little or no modification. The WT9 Dynamic from airframer Aerospool spol s.r.o is a perfect example of an existing design adapted to LSA specs. Made in the Slovak Republic, it’s a very attractive machine, with a 9m/29.5 ft wingspan and 6.4m/21 ft overall length (prop to tail). Originally built to European Ultralight standards, it was modified for LSA rules primarily by replacing its 100-hp Rotax 912 UL engine with the 80-hp ULS version.The fuselage is primarily urethane foam-cored carbon fiber/epoxy laminate, but aramid fiber is used to make the skins around the cockpit for additional impact protection. The spar and most load-bearing structures are carbon-fiber-reinforced composites. The wingskins and tailplane use a combination of glass and carbon in a foam-cored sandwich construction. The result is a very light aircraft; its empty weight with standard equipment is 583 lb/259 kg.

Unique core and constant-chord wing

The two-seat Bilsam Sky Cruiser, manufactured by Bilsam Aviation (Poznan, Poland), has a wingspan of 26.5 ft/8m, a length of 21.6 ft/6.6m, an empty weight of 670 lb/304 kg (it reportedly uses only 4 GPH at cruise), and a factory-installed parachute — a growing LSA trend. Especially interesting is the use of Parabeam 3D composites, developed by Parabeam BV (Helmond, The Netherlands) in primary structures. Parabeam 3D Glass Fabric is woven from E-glass yarn and consists of two deck layers (upper and lower dry preforms) connected by vertical yarns. That is, z-directional yarns are stitched through the deck layers, tying them together in an integral sandwich structure, and the deck layer preforms absorb the resin. Due to capillary forces, as the fibers are impregnated, the fabric rises to a preset height (from as thin as 3 mm/0.12 inches to as thick as 24 mm/0.94 inches). Thus, in a single step, a complex construction is created with z-axis fibers that pick up the shear and compression/buckling loads much as a foam or honeycomb core would, with z-axis compressive strength of 9.6 MPa/1,392 psi; z-axis compressive modulus of 60 MPa/8,702 psi; shear strength (warp) of 0.8 MPa/116 psi and (weft) 1.8 MPa/261 psi; and shear modulus of (warp) 14.4 MPa/2,088 psi and (weft) 96 MPa/13.9 Ksi.Parabeam is used as the main core material in the fuselage, wingskins and flying surfaces, which feature carbon fiber/epoxy faceskins wet out with L 1000 epoxy resin with VE 5195/H hardener from Bakelite AG (Iserlohn, Germany, now part of Hexion Specialty Chemicals, Carpenterville, Ill.). Plain-weave carbon (±45°) is used in critical areas, such as wing and landing gear attach points. Cored parts that don’t use Parabeam feature polyvinyl chloride (PVC) foam (Herex C70 from Alcan Airex AG, Sins, Switzerland) that maintains design strength at up to 150°C/302°F. Laminates are vacuum bagged and go through an unusual cure cycle: room-temperature cure for 15 hours, then oven cure for two hours at 60°C/140°F, and two more at 70°C/168°F, and then postcure (unbagged) for 15 hours at 65°C/150°F.

Wasp-waist, wide wingspan

From the Czech Republic comes the Gobosh 800XP Composite Low Wing, marketed in the U.S. by Gobosh Aviation (Moline, Ill.). Gobosh Aviation brought the 800XP to life through a collaboration with The Kabrt Brothers, the most productive and successful airframe designers in the LSA class. The plane is manufactured by Aveko s.r.o. (Brno, Czech Republic). This attractive, well-proportioned machine has a wider 31.5 ft/9.6m wingspan on a 20 ft/6.1m fuselage, and at 760 lb/345 kg (empty) it still leaves 560 lb/254 kg of room for occupants and luggage. It sports the “wasp waist” that has become common in composite aircraft, especially in LSAs, and with good reason: Pinching down the tailcone helps reduce the wetted area and therefore the equivalent flat plate drag area. If it’s done correctly, some pressure recovery can be obtained, meaning that higher pressure will develop in the more rear-facing areas. This changes the pressure distribution, and the net effect is, again, lower overall drag. This can be accomplished much more easily with composites, which allow compound curves — shapes that, in aluminum, would require prohibitively expensive tooling and equipment.The airframe is made almost entirely of carbon fiber/epoxy sandwich, except for the wing attach structure in the fuselage, which contains some aramid fiber — not so much to pick up flight loads but to increase crash impact-resistance in the cockpit area and prevent shattering of carbon laminate.

Canadian “camper” with cavernous cabin

Explorer Aeronautique Inc. (Shawinigan, Quebec, Canada) bills its Ecoflyer as the “biggest LSA,” and they’ll get no argument here. Ecoflyer has a 34 ft/10m wingspan on a 20.5 ft/6.2m hull. The fact that it comes from Canada says much about its enormous internal capacity (by LSA standards): It has two seats plus room for camping gear, kayaks, bicycles or anything else that will fit in its 152 ft³ (4.3m³) cabin. Indeed, at the Ecoflyer display during the recent EAA AirVenture event in late July (see “Learn More”) there was one on display with large double doors opened up on the left side to reveal a table and chairs, with breakfast service for two arranged replete with a coffee pot (see photo, at right).Control surfaces, as well as tail surfaces, are a sandwich that consists of glass fiber/epoxy over a ROHACELL PMI (polymethacrylimide) foam core supplied by EVONIK Röhm GmbH (Darmstadt, Germany). The wing spar is the standard ±45° glass fiber-reinforced shear web with unidirectional caps. The remainder of the ship is a glass/epoxy-skinned sandwich with a foam core of Divinycell from DIAB Inc. (DeSoto, Texas). This results in an empty weight of about 675 lb/306 kg, which is pretty respectable, given the plane’s size.

Ecoflyer is the little brother of another hyperutilitarian aircraft called the Private Explorer, a truly huge, single-engine aircraft that can be ordered with, literally, everything … including the kitchen sink, a stove, fold-down table and beds, cabinet space and, very soon, a toilet and shower. Yes, it’s big. So big that, even with 300 hp installed, it’s actually a bit slower than the Ecoflyer.

Flying amphibious sports car?

Speaking of landing on the water, the stunning full-scale prototype Icon A5 amphibian from Icon Aircraft (Los Angeles, Calif.) made a huge splash (no pun intended), drawing quite a crowd at Oshkosh this year not long after its maiden flight on July 9. The design crew consists entirely of talent that jumped ship from Mojave, Calif.-based Scaled Composites (Burt Rutan’s legendary aircraft design firm) to join Icon cofounders Kirk Hawkins and Steen Strand in their efforts to create a plane in the LSA category that would “do for recreational flying what personal watercraft did for boating.” It shows (see photo, at right). The Icon A5 comes complete with an instrument panel that looks for all the world like it came out of a Lamborghini sports car and is molded in a similar fashion to instrument panels on production automobiles.

The rest of the plane doesn’t disappoint. Its large, raked windshield/canopy tilts forward for entry and egress, fits flush with the smooth, flowing lines of the upper fuselage, and has removable side windows for a more open-air ride. The headlights and landing lights have sports car-like flush fitting lenses. Its long wings (34 ft/10.4m span) can fold up close to the fuselage, allowing storage in a large garage (nose to tail, it’s 22 ft/6.7m long). The craft also comes with a trailer.

All told, the A5 is a unique approach to a new and extremely competitive area of aviation. There simply aren’t any other flying sports cars that actually look like a sports car. Add the capability for water landing, and you’ve got a potential hot seller. According to Icon, the prototype is scheduled to undergo several flight-test phases over the next year before the design is finalized. Then a preproduction model will be built to verify FAA and ASTM compliance before the plane goes into production in late 2010.

Tandem-seater molded in Thailand

There aren’t many tandem-seat LSAs around, but the MSONE, manufactured by MySky Aircraft Inc. (New Smyrna Beach, Fla.), with its 30-inch/762-mm wide cabin, is a good example. The plane weighs in empty at 710 lb/322kg, with a 30 ft/9.14 wingspan. It burns less than 5 GPH and cruises at 120 KTAS (knots true air speed) with a far-reaching 636 nautical-mile range.The MSONE is an international effort. The tooling is produced near Bangkok, Thailand by Tiger Composites under the supervision of MySky and Advanced Composite Solutions LLC (New Smyrna Beach, Fla.). The prototype parts, final assembly and flight test of production examples will take place in Florida. However, when the plane goes into production, the parts also will come from Thailand.

Interestingly, the wing is of the constant chord, or “Hershey Bar,” variety, in which the ribs are all the same size and shape. This design is neither common nor particularly advantageous in a composite aircraft. In an aluminum airship, it means that only one expensive tool needs to be made to form them. In a composite machine, however, ribs of different sizes can be made by comparatively inexpensive methods. The constant-chord wing does offer a safety edge: It tends to wash out (twist) at high angles of attack, causing the wing root to stall a bit before the wingtips so that the ailerons will still function and provide roll control while the pilot arrests the stall development, keeping the aircraft from falling off into a spin.

The MSONE’s spar is a deep box beam with carbon caps. The ribs are fiber-skinned foam and are apparently in a laminar-flow airfoil section, given their shape and the positioning of the spar along the chord line. The skins are foam cored and secondarily bonded to the spar and ribs.

A roadworthy LSA?

Although many people have attempted to build a “flying car,” none have ever gone into production. The most successful attempt, by far, was Molt Taylor’s Aerocar, built in Longview, Wash., in 1949. Readers who are old enough to remember might recall the Bob Cummings Show, where the actor/comedian would land his Aerocar (which was actually his), remove the wings and tail and drive home during the opening credits. The wings and tailcone fit into a trailer that could be left at the airport or towed for storage at home. The “car” portion had a rear engine and a power takeoff/driveshaft that was connected to a propeller in the tailcone. The tail surfaces consisted of a V-tail with a vertical fin below and a small wheel in the tip for propeller clearance and added directional stability. When the parts were separated, the car portion was roadworthy; with its wings, tailcone and empennage, it was also airworthy, with docile handling characteristics and a cruising speed of 120 mph/193 kmh.On display at Oshkosh this year was one of the latest attempts, courtesy of Terrafugia (from the Latin terra, for earth, and fugia, for flight). The Woburn, Mass.-based company’s craft is dubbed the Transition, and if things work out, that’s exactly what it will do: transition from a flying machine to a ground vehicle. (Don’t call it a “flying car.” They insist it’s a “roadable aircraft.”)

The Transition is a three-surface aircraft, with a canard up front (see photo), the main wing in the middle and a “flying tail” or stabilator in the rear (the canard helps reduce the width of the rear elevator to a “roadable” size). It features carbon composites — it’s light enough to fly but reportedly sturdy enough to pass auto industry crash tests — a ~$148,000 price tag and is expected to go into production as early as late 2009.

As has been true in the past, this update of composites use in general aviation LSAs is, at best, representative. The sheer number of projects in small aircraft categories precludes their inclusion in a single article. But that fact alone says much about the positive impact composites are having — and will continue to have — on the field of aircraft manufacturing.

Related Content

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreBraskem demonstrates PP solutions using Weav3D composite lattice technology

Partnership combines Braskem’s polypropylene sheets with Weav3D Rebar for Plastics technology to address new structural, automotive applications requiring high-strength, lightweight material solutions.

Read More3D-woven composites find success in aerospace, space

CAMX 2024: Bally Ribbon Mills experts are displaying the company’s various joints, thermal protection system (TPS) technologies and other 3D woven composites for mission-critical applications.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

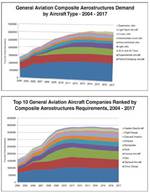

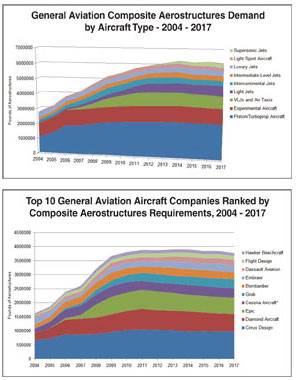

Aviation Outlook: Composite aerostructures in General Aviation

Although the math is fuzzy and once helpful category distinctions are blurring, the forecast for this sector’s use of fiber-reinforced polymer remains strong.

Read More2007 Oshkosh Fly-in showcases jets and kits

The annual EAA AirVenture event hosts a large crop of composites-intensive aircraft designs for the VLJ and homebuilt markets.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More