Composites in tornado shelters

A new design aims to defeat the threat from debris, both as heavy piles preventing exit and as projectiles traveling at ballistic speeds.

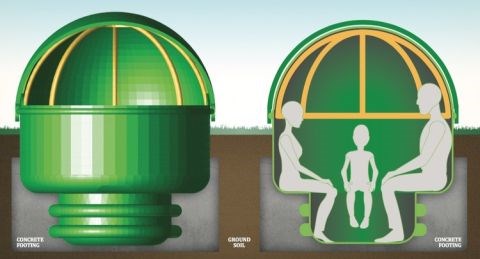

The TornadoPod storm shelter uses glass and Innegra fiber/epoxy composites to resist ballistic debris and tornado winds. SOURCE: Tornadopod.com.

In April of 2011, a mile-and-a-half-wide tornado ripped through Alabama, leaving a trail of death and destruction from Tuscaloosa to Birmingham and beyond — roughly 81 miles. In some areas, debris piled as high as three feet, trapping survivors who could not open the shelter’s hinged door due to the weight of the debris. Inventor Wes Kouba, now president of TornadoPod (Frisco, TX, US), wanted to find a better solution.

In 2012, Kouba applied for a patent on a shelter with a sliding door that can be removed easily by extracting hinge pins from the inside and releasing the door if necessary. He also wanted to make the shelter cost-effective. The US patent for his TornadoPod was issued in 2014. Now he had to figure out how to make it.

Wes Kouba’s patented TornadoPod is designed to deflect debris and enable occupants to easily exit by sliding open the storm shelter door. Even if completely blocked by debris, occupants can remove the composite door’s hinge pins and remove it to create an exit opening.

SOURCE: TornadoPod Twitter feed, NBC 5, KXAS-TV.

The TornadoPod’s design features a unibody construction with a threaded base that anchors into the ground, secured by 5400 kg of concrete. The upper section of the circular structure is roughly 1.5 m in diameter and seats up to 6 adults, capped by a domed steel cage and exterior ballistic shield. The steel cage prevents crushing while the ballistic shield dome incorporates a sliding hatch that can be opened, even if the pod is covered in debris.

SOURCE: TornadoPod.com

Many storm shelter products include fiberglass reinforced plastic (FRP) composites. Kouba knew this was a good starting place for the strength and lightweight he needed for the TornadoPod dome, but achieving resistance to ballistic debris was not as clear cut.

He tried a number of E-glass and/or specialized polyethylene ballistic fiber materials, but all had issues with excessive costs or their inability to be easily molded into the desired profile. “The fibers were difficult to shape and bond in the way needed to efficiently make the pod shell,” explains Russ Emanis, senior composites engineer for Innegra Technologies (Greenville, SC, US). After Kouba found Innegra high-modulus polypropylene (HMPP) fiber on the internet in 2015, Innegra Technologies partnered with him, performing testing and a significant amount of laminate design and process development.

Using Innegra to Withstand Impact

Five different 610mm x 610mm composite panels were made using woven glass fiber and Innegra fabrics and Endurance Technologies (South St. Paul, MN, US) epoxy infusion resin. Based on ballistic testing of these panels, the laminate design for the Tornadopod shell was developed, with a safety margin of 30% above what was needed to pass the FEMA 320/361 criteria for Windborne Debris Hazards. Exposed surfaces of tornado shelters must be tested to emulate wind speeds of 250 mph, including shooting a 15-lb wooden 2x4 from a cannon, impacting the shelter at 100 mph.

Click square in lower right of each video for full-screen

and hit esc on your keyboard to exit back out.

The ballistic shield laminate was finalized as multiple layers of woven glass fabrics and 100% Innegra fabrics, with a total thickness of 9.5 mm. “Innegra brings a ductile property to the glass/epoxy composite and dissipates impact energy very quickly,” says Emanis. “You can actually see the shock wave move through the structure.” He adds that Innegra does not provide an isolated energy absorption area, but the ability for the structure as a whole to get rid of the energy. This is also why there is no localized impact damage, which is key for preventing penetrations and injury to those inside. The TornadoPod was tested in February 2016 and has now achieved full certification in accordance with FEMA requirements for tornado shelters.

TornadoPod molds in process. SOURCE: TornadoPod.

Parts are in production and Kouba is looking at expanding the product line to panels for safe rooms inside of residential structures. For its part, Innegra Technologies is also looking at new applications, including skins for wind blades to help resist damage from bird strikes. “These are fairly common,” says Emanis, “and cause small fractures in the FRP shell of the blade. Water then gets in and freezes, propagating the cracks and eventually causing blade failures.” He notes leading edges are another potential application, “to mitigate bondline issues they’ve had there in the past. Unlike current solutions, Innegra will flex with the blade, preventing hard spots or stress concentrations.”

Emanis reports that Innegra is also being tested in impact beams for automotive applications. “These are structures you find behind the bumper and inside of doors,” he explains. “Innegra allows the part to flex more before failure, enabling the parts to be lighter and more efficient.” Emmanis points out that typical composite beams use a lot of carbon fiber unidirectional reinforcements which are stiff, but the fibers crumple against one another during impact and fail. “Innegra allows the CF to move without failure,” he says, “so basically, you’re getting more impact resistance with less weight.” However, he warns that it is important to use resin systems that match Innegra’s elongation in order to take full advantage of what the fiber has to offer.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreComposite molding compound replaces Invar for lightweight small satellite structures

Patz Materials and Technologies and Lawrence Livermore National Laboratory developed a new monolithic optics housing with 80% less weight, near-zero CTE and the high-volume manufacturing required for commercial space.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreFrom the CW Archives: Fast-cure epoxies for automotive fabrication

Sara Black’s 2015 report on the development of snap-cure epoxies for automotive manufacturing still resonates today.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More