CW’s Focus on Design article series explores the composite materials and design tools used to fabricate specific composite parts and structures. Applications range from aerospace and automotive to wind and industrial.

The goal of Focus on Design is to help designers and engineers stay up-to-date with the latest developments in composite materials and design, and to inspire new ideas and approaches to product development.

Here are the all-time top ten Focus on Design articles, according to Google Analytics.

10. Multi-composite thrust chamber aims to boost rockets, reduce cost for New Space economy

Black Engine uses new, microporous CMC liner for transpiration cooling and multiple lightweight composites in modular design that offers increased lifetime and lower maintenance versus current launch vehicle engines.

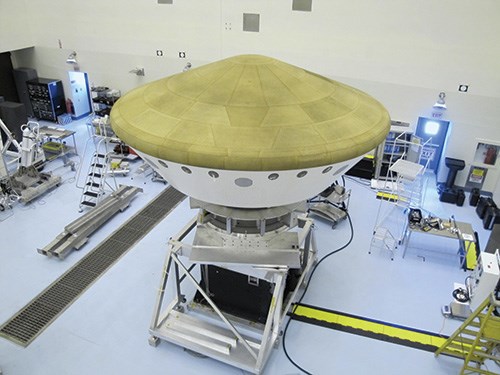

9. Composites carry the Curiosity rover to a safe Mars landing

From launch to touchdown, composites performed in flight and stuck the landing!

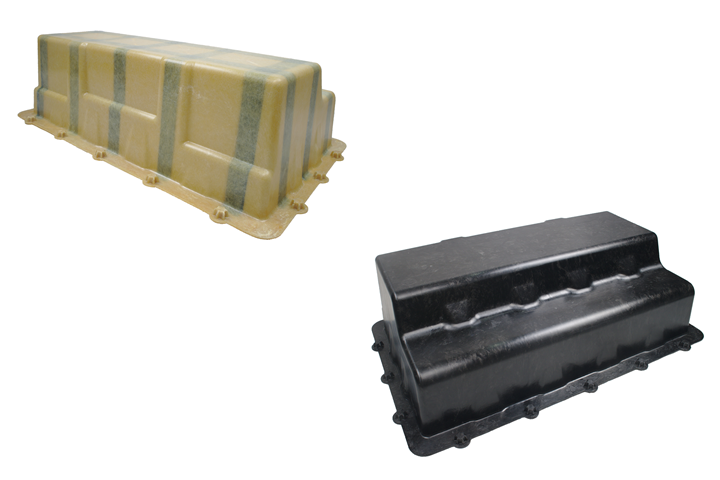

8. SMC material configurations tailored to automotive battery enclosure design

SMC battery cover offers various module configurations, levels of performance, mass and cost for electric vehicles.

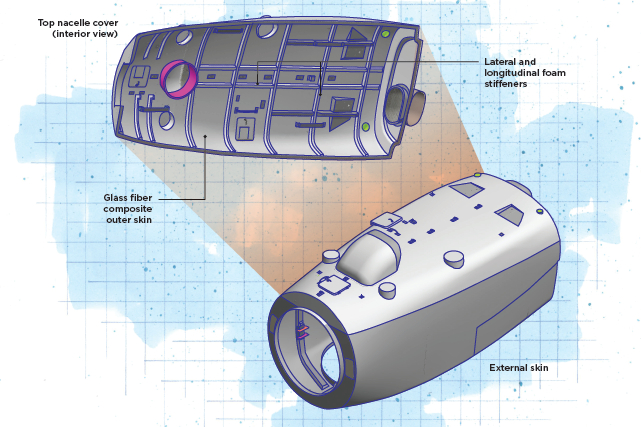

7. Optimizing a wind turbine nacelle cover to meet LCOE demand

Suzlon Group redesigned a composite nacelle cover with in-situ molded stiffeners to reduce manufacturing and material costs while maximizing part performance.

Illustrated by Susan Kraus

6. Modernizing the mechanical rotor sail

Composites are key for Norsepower’s award-winning redesign of a century-old rotor sail for reducing carbon emissions on passenger and cargo ships.

5. BMW rolls out multi-material Carbon Cage with 2022 iX vehicle line

For its new battery-electric iX sports activity vehicle, BMW combines CFRP strategies from previous i3, i8 and 7-Series designs and adds CFRTP for a lightweight, rigid frame.

4. Indutrial-scale wave energy system enabled by mobile filament winding

Sweden-based CorPower Ocean designed its 9-meter-long, filament-wound GFRP buoy prototype for high-efficiency, durable wave energy generation and fast, on-site manufacture.

3. Leveraging motorsports composites for next-gen rotorcraft

FastCan consortium integrates hollow, solid and cored CFRP into single-cure, single-piece canopy for reduced weight and cost.

2. Designing for automated composites manufacturing of low-volume aerostructures

The commercial aerospace industry is heavily focused on design for efficient high-rate manufacturing, but there is still need for automated, affordable fabrication of low-rate aerostructures.

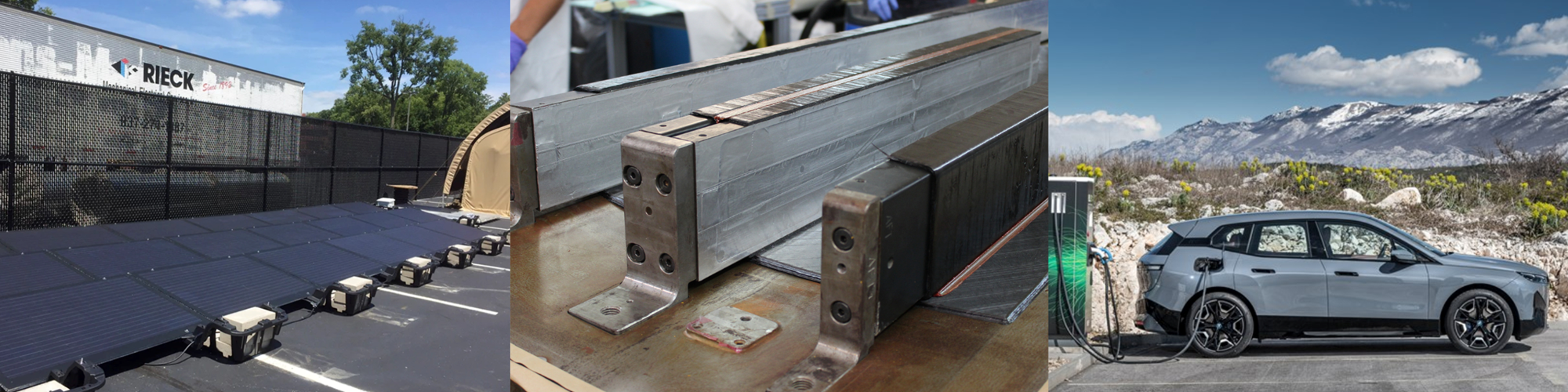

1. Simplifying the solar panel with composites

Replacing glass and aluminum with a polymer/cored polymer composite laminate ups panel durability at reduced weight.

For more Focus on Design articles, click here.

Related Content

-

Carbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

-

Seat frame demonstrates next-generation autocomposites design

Light weight, simplified/cost-effective manufacturing, passenger comfort and safety informed materials and process innovations and won awards for the 2022 Toyota Tundra‘s second-row seat frame.

-

Aviation-specific battery system uses advanced composites to address electric, hybrid flight

BOLDair’s composite enclosure, compression structures and thermal runaway management enables high-performance electric energy storage.