Change, better yet, rapid change. This best characterizes the current state of unmanned aerial vehicle (UAV) design and manufacturing. One big change is the terminology. UAVs are now drones, and drone technology, at one time, almost exclusively confined to military missions, are defying limiting definitions and finding use in hosts of cutting-edge industrial, commercial and consumer applications. No longer limited to control by humans on the ground, drones also are shaping the destiny of autonomous technology — what it will be and how it can be used.

On the radar: Drones for communication, automation

One of the great promises of composites use in drones is as an enabler for persistent, long-duration systems that provide wide-area Wifi Internet access. Ideally, such drones would be solar-powered and able to serve land areas of many square miles with uninterrupted Internet access for weeks at a time. There are at least two programs pursuing this technology, and results so far are promising, if mixed.

One is the work of social media giant Facebook (Menlo Park, CA, US), and the other, a product of the Massachusetts Institute of Technology (MIT, Cambridge, MA, US). Each has built and flown prototypes and aims to achieve unprecedented UAV flight durations with radically new designs, which, by necessity, hope to maximize the advantages of advanced composites.

In development since 2014, Facebook’s Aquila (Fig. 1), an all-carbon-fiber composite, solar-powered, four-propeller drone, has been test flown twice. In 2016, it was aloft for 96 minutes below 305m, and this past year, it flew for about 106 minutes, reaching an altitude of 914.4m. The Aquila is intended for big things: Aquila’s stated target customer base is the several billion people around the world without reliable online access. Given the enormous geographical scale, the drone must be capable of very long, uninterrupted flight, and that, in turn, has profound consequences for Aquila’s flight performance and design parameters. Facebook must build and launch pilotless aircraft capable of continuous flight for months and at very high altitudes — 60,000-90,000 ft (18,290-27,430m). At this height, the drone can provide WiFi coverage over about 60 square miles. When the technology is perfected, Facebook CEO Mark Zuckerberg has stated he intends to build a fleet of the drones.

Although this is potentially good news for the composites industry, Facebook has released little specific engineering detail about the Aquila or the carbon fiber materials and laminate used to construct it. CW has learned that the flight-tested version has a “wingspan wider than a Boeing 737,” which puts it in the range of 110 ft (±34m). Foregoing the extra weight and drag of conventional landing gear, the Aquila also is equipped with a Kevlar “landing pad” bonded to the bottom of the motor pods, one reason it only weighs about 1,000 lb (454 kg), with roughly half of that mass accounted for by batteries. Zuckerberg, however, has made clear that the drone needs to be made even lighter.

When traveling upwind, the drone flies, by design, at a land speed of only 10-15 mph, which keeps it centered over the target area intended to receive signal. The communications system will use lasers to transfer data, which is about 10 times faster than land-based fiber optics. On the drone’s second, most recently flown version, an unspecified coating material applied to the wings created a “smoother finish” and is credited for doubling its climb rate to 54.9m/min, compared to the climb rate of the first drone. That said, it remains to be seen if Aquila’s ambitious flight duration goals can be met using only solar power. The project’s main challenges in the next phase, according to posts on the Aquila Facebook site, are solar panel efficiency, battery storage and achieving acceptable cost paradigms for operation. Facebook says it intends to expand the test program to include drones with different “form factors, sizes and weights,” and fly to higher altitudes in the next round of test flights.

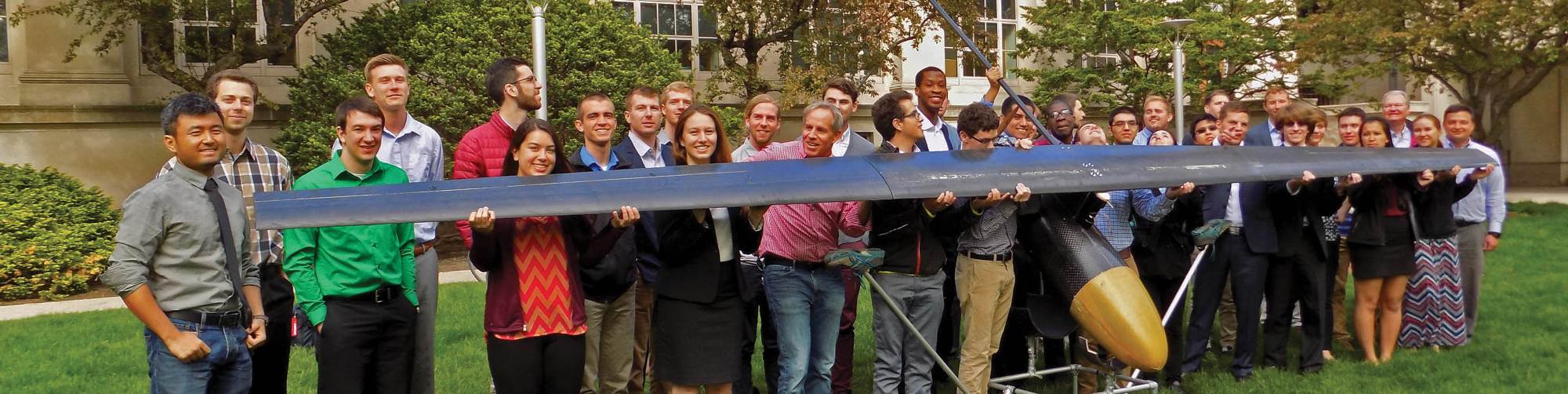

Meanwhile, a team of MIT engineers has designed, built and tested a UAV with a 24 ft (7.32m) wingspan, fabricated entirely from composites reinforced with carbon fiber and Kevlar (Fig. 2), The objective of the UAV development project, dubbed Jungle Hawk Owl and funded by the US Air Force (Gateways Branch, AFLCMC/HNAG, Hanscom Air Force Base, Bedford, MA, US), is a bit more modest than that for Facebook’s Aquila. The goal is to build a drone capable of staying aloft for five or more days, in high and low geographical latitudes, in all seasons, at an altitude of approximately 4,572m. Such a drone would be designed to perform as a communications hub, providing temporary Internet/phone connections over a large area in the event of a wide-scale power or service outage.

The drone’s design was modeled on a glider, with a typically thin aerodynamic profile. The first, full-scale version, test flown this past year at a maximum altitude of 122m, has a wing thickness of 42.4 mm tapering to 20.8 mm, and a total, empty weight of only 12.7 kg. After minor adjustments to the aircraft and its automotive rooftop launch system are complete, high-altitude flight tests are scheduled for this summer, with the drone carrying a full payload of communication equipment and fuel, weighing up to 45.4 kg.

John Hansman, professor of aeronautics and astronautics at MIT and one of the staff supervising the student research, a collaboration between MIT and the MIT Lincoln Laboratory (Lexington, MA, US), reports that the wings comprise a core sandwich molded in a two-step process. To achieve the necessary aerodynamic precision, the wing’s upper surface skin was molded separately, via vacuum infusion, from one ply of unidirectional carbon fiber fabric oriented 90° to the length of the wingspan. To make the bottom wingskin, spar caps of varying thickness were molded from unidirectional fabric and placed in the mold. Styrofoam was then placed around and between the spar caps, and the bottom skin was vacuum bagged in place against the construction. The top skin was then fitted to the bottom and wrapped in 12K tow. All fabrics were infused with West Systems 105, a low-viscosity epoxy supplied by Gougeon Bros. Inc. (Bay City, MI, US). All molds were CNC-machined from RenShape 440 polyurethane foam, provided by Freeman Manufacturing & Supply Co. (Avon, OH, US).

To make the fuselage, which houses its gasoline engine (see the Side Story “Drones: MIT software casts doubt on solar-powered UAVs”) and fuel tank, the team used a simple cylindrical concrete mold, applied two plies of unidirectional fabric, one at 90° and one at 45°, to the inner diameter of the tube, then used a toroidal vacuum bag positioned through and around the tube, to vacuum infuse the fabric, with the outside layer of the laminate positioned against the inner wall of the tube. To fabricate the nosecone, which contains the communications electronics, an external conic-shaped mold was machined in two halves from foam. A single layer of 0° Kevlar fabric was laid up on the mold halves (which had been bonded together) and vacuum infused.

Drones — new players in industry

Drones are having an impact in the industrial realm, going aerially where it is more difficult and expensive for workers and conventional machinery, including robots, to go.

One application with a potentially huge future is safety inspection of aging wind blades. UAVs equipped with cameras for military surveillance were one of the earliest uses of the technology. Today, drones fitted with special cameras, and operated autonomously by extremely sophisticated software, can inspect a giant wind turbine’s rotor blades in as little as 15 minutes, (inspection by a human can take an entire day), and forward visual evidence of damage to a Web portal for onscreen viewing by inspectors in more comfortable surroundings. CW covered this growing drone-based business phenomenon in its May issue (see “Service & repair: Optimizing wind power’s grid impact”).

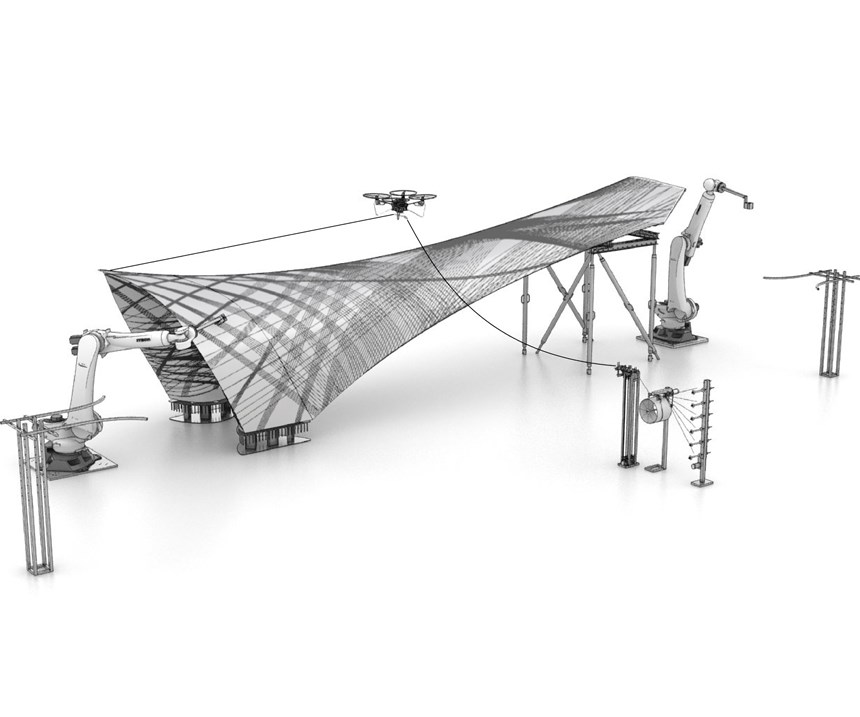

A group of researchers at the University of Stuttgart’s (Stuttgart, Germany) Institute for Building Structures and Structural Design and Institute for Computational Design have demonstrated a novel and clever method of using drones in combination with industrial robots to fabricate a long-span composite structure via a fiber-winding process. Collaborative winding, as it is called, entails the use of two stationary industrial robots and a custom-built, lightweight drone or UAV “go-between” to fabricate long-span structures in the interstitial space between the robots (Fig. 3). In simple terms, the fabrication layout establishes a favorable division of labor which capitalizes on the strengths of both machines — the robots are used to precisely place the resin-impregnated roving on the winding frame, while the drone shuttles the fiber from the spools to each of the robotic arms, thereby circumventing the limitation imposed on part size by the robot end-effector’s reach envelope. Until now, the primary alternative to fabricating large parts exceeding the reach of the robot was to build the part by modularization, a process that is less than ideal, especially if the fabricated structure is load-bearing.

The project was the work of eight researchers at the University and is summarized in the paper “Multi-Machine Fabrication,” published in the November 2017 edition of Acadia, a journal of interior architecture and spatial design. The workcell comprised two, 6-axis KUKA (Augsburg, Germany) KR 210 R3100 Ultra robots, equipped with steel extensions, a hydraulic gripper to grasp the winding effector from the UAV, and an infrared camera used to synchronize the robot’s locations with the UAV. A custom tension mechanism, based on tension devices used in extrusion and rolling applications, provides control over fiber tension as it is passed from the fiber source to the UAV or robot.

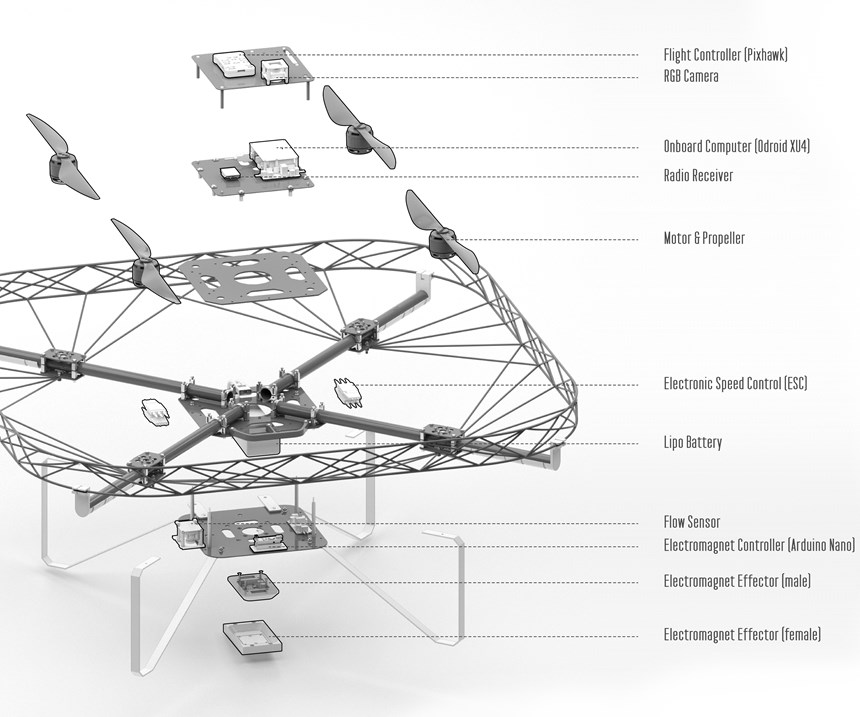

James Solly, one of the project researchers, says the final design of the custom-built drone was derived from four earlier prototypes, in a design process that enabled the team to optimize the drone’s weight and stabilize its flight behavior. Parts for the drone body were machined from standard carbon plate, while the craft’s arms were fabricated from 20-mm carbon tubing. Other, smaller pieces, such as connectors and spacers, were 3D printed from polylactic acid (PLA). Drone dimensions are approximately 92 by 92 by 31 cm and the vehicle can carry a payload of about 2 kg.

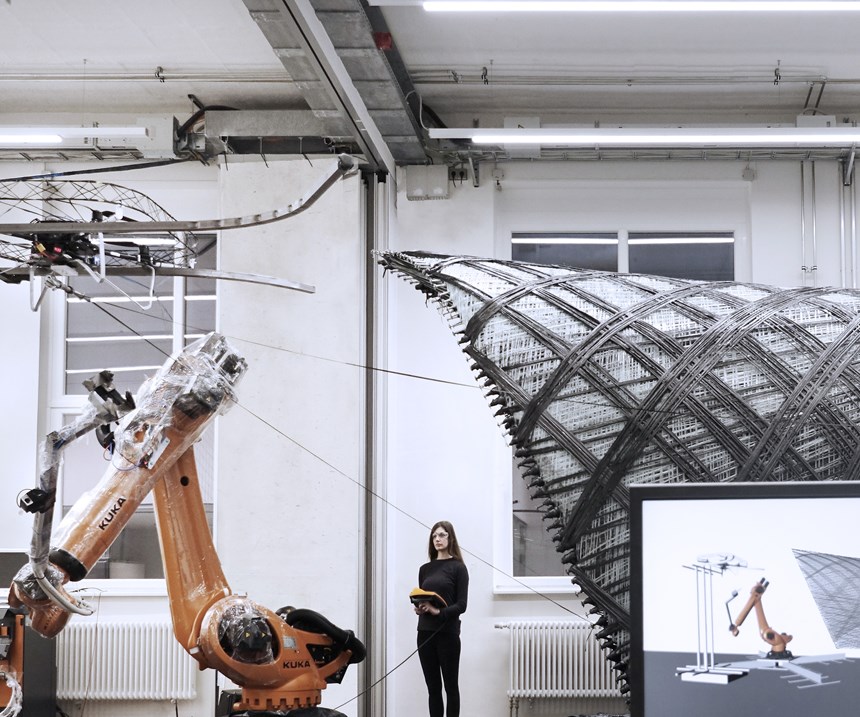

To wind a single anchor point, the robot arm travels around the winding frame with the impregnated fiber elevated above the laminate. Upon reaching the anchor point, the robot winds the fiber around it, then returns the winding effector to the landing platform where the UAV is waiting. After exchange is confirmed, the tension mechanism switches to low tension, and the drone carries the unspooling fiber to the next robotic platform. The researchers used the robotic-drone cell to fabricate a 12m long demonstrator cantilever as an example of the shape and size of parts that could not have been produced by traditional automated fiber-winding setup (Fig. 4). The part comprised single-end continuous glass roving, SE1500-2400tex donated by Lange+Ritter GmbH (Gerlingen, Germany) and SIGRAFIL continuous carbon fiber tow, CT50-4.0/240-E100, donated by SGL Technologies GmbH (Wiesbaden, Germany). Fibers were pre-impregnated with EPIKOTE MGS LR 135 epoxy resin formulated with EPIKURE MGS LH 138 curing agent, supplied by Hexion (Columbus, OH, US). The part was fabricated using prepregged fibers and dry fibers impregnated in a fiber-dip resin bath. Solly reports the process demonstrated by the project is best suited to producing horizontal structures with long spans between vertical supports, such as ballroom roofs or pedestrian bridges in which the reduction in self-weight can be expected to yield significant reductions of materials used and cost. He reports that he and his colleagues will elaborate on the process and its applications with a paper being presented at the upcoming International Association for Shell and Spatial Structures (IASS 2018) conference, July 16-20, Boston, MA, US.

In another industrial-related project, a research team at the MIT Media Lab is investigating the use of drones to locate and identify warehouse inventory via radio frequency ID (RFID) tags. A need for improvements in inventory accounting practices, brought on by the increase in scale of modern warehouse and shipping operations, has been acknowledged for some time. Manual scanning is laborious, costly and prone to error. Walmart, for example, reported in 2013 losing more than US$3 billion in revenue due to mismatches between its inventory records and its actual stock.

The MIT team has successfully developed a prototype that enables small, lightweight drones with flexible plastic rotors — the only type approved for use in close vicinity to humans — to read RFID tags from tens of meters away while identifying the tags’ locations with an average error of about 19 cm.

The Bebop-2 drones used for the study are manufactured by Parrot Corp. (Paris, France). Designed specifically to exhibit low vibration for applications such as photography, the drone features a fuselage made from glass-filled Grilamid TR nylon, supplied by EMS-CHEMIE AG (Domat/Ems, Switzerland). Each drone weighs about 500g and can fly autonomously for about 25 minutes. Although they are approved for use around people, the drones are too small to carry an RFID reader with a range of more than a few centimeters. Instead — this is the key research breakthrough — the drones are used to relay signals emitted by a standard RFID reader to a RFID tag. When the signal reaches the tag, the tag then encodes its identifier on the signal before sending it back to the drone. The drone forwards the signal to the reader, which decodes the identifier, and thus the item and location of the item. The team is currently working to improve the precision of the locating mechanism over longer distances, as well as ways to improve the speed and scalability of the process.

Innovation spurring new drone applications

Materials suppliers, contract 3D printing manufacturers, and printing equipment suppliers report growing business from drone manufacturers, and are developing new products and capabilities to service this business.

Clearwater Composites LLC (Duluth, MN, US) produces a line of carbon fiber tubing and plates it supplies to manufacturers of industrial equipment, robotics, aerospace, sporting goods and UAVs. Tubes, in a variety of shapes, are primarily made by roll-wrapping unidirectional carbon fiber epoxy prepreg on a mandrel, with a cure at 250°C. The tubes are made in standard-, high- and ultra-high modulus grades, the latter made from pitch fibers. The company manufactures plates in a range of thicknesses, in sheets up to 1.2m by 2.4m, from similar materials via compression molding or vacuum infusion. President Jeff Engbrecht says its UAV customers are typically North American-based companies that design and build UAVs for upper-end industrial and aerospace applications.

Clearwater, he reports, is supplying one of its customers, a UAV/drone designer and manufacturer, with a custom-tapered, thin-walled (0.03-inch/0.76-mm) tube, made from Toray Industries’ (Tokyo, Japan) high-modulus M46J carbon fiber. The tube, for an unspecified new application, is round at one end, then tapers to an oval shape at the other end.

Stratus Aeronautics (Burnaby, BC, Canada) manufactures drones primarily used for conducting magnetic and aerial surveys in scientific research, mining, military and other applications. Designed and built in both fixed-wing and multi-rotor configurations, these survey drones provide significant cost advantages over piloted craft.

The company’s fixed-wing Venturer UAV (Fig. 5) is a small, lightweight aircraft, powered by a 100-cc, two-stroke gas engine and is capable of long-duration (>10 hr) missions — not a possibility with a piloted craft.

The plane features an airframe molded from carbon fiber prepreg, wings comprising a semi-monocoque with foam cores, and a monocoque fuselage without cores.

Curtis Mullen, the company’s chief technical officer, says design and testing is nearly complete for a new electric, multi-rotor UAV. At 3m in length and weighing about 15 kg, it is, except for the electronics, built entirely from carbon fiber composites. “The chassis is a self-aligning, monocoque structure made of CNC-routed carbon plate,” Mullen reports. Tubular carbon of varying fiber orientation and moduli, depending on local loads, comprises the remainder of the structure. At CW July press time, the company planned to complete construction and flight testing in the June/July timeframe and introduce Venturer to the market later in 2018.

Drones dovetail with 3D printing

Given the rapid development of drone technology, it should come as no surprise that drone builders have provided the impetus for additive manufacturing of composites. Drone designers are not only using large-format 3D printers to do the rapid prototyping for which the processes were first conceived, but also, as those processes evolve, to provide tooling and finished parts as well, to meet quick turnaround times required by drone OEMs.

Impossible Objects (Northbrook, IL), for one, recently partnered with Aurora Flight Sciences (Manassas, VA) to 3D print a 76-by-38-mm rear stabilizer mount from high-density polyethylene (HDPE) reinforced with 25.4-mm chopped carbon fibers, using its Composite-Based Additive Manufacturing (CBAM) technology. The part was installed on a new aircraft in development at the time, replacing a part made from unreinforced nylon that was breaking. Although additive manufacturing technology has frequently been used to make prototype or test parts, Impossible Objects’ CEO Larry Kaplan says the company is currently working on securing several commercial, higher-volume applications for parts in drones. Details of the applications cannot yet be detailed, but Kaplan reports that they will involve new, high-temperature-resistant, carbon fiber/nylon and carbon fiber/PEEK materials the company has developed. “We are the only composites additive manufacturer with a reinforced PEEK material,” Kaplan claims, noting materials with high temperature resistance are increasingly in demand for parts and molds.

Printer supplier Stratasys Inc. (Eden Prairie, MN, US) is partnering with materials suppliers and aerospace/drone fabricators in the ongoing development and commercialization of its 3D printed tooling technologies for the molding of composite parts. Timothy Schniepp, senior director, composite solutions at Stratasys, says the company’s fused deposition modeling (FDM) machines can produce most tools in two to three days or less, meaning a customer can be molding parts in less than a week. The company’s high-temperature material, Ultem 1010, a polyetherimide (PEI) manufactured by SABIC (Pittsfield, MA, US), is a general purpose, unfilled material suitable for the manufacture of all lay-up tooling, including tools autoclaved to temperatures up to 300°F.

Swift Engineering Inc. (San Clemente, CA, US) used FDM and Ultem 1010 to manufacture matched halves of a compression mold for a UAV’s carbon fiber-reinforced epoxy propeller blades. The 356-by-102-by-51-mm tools took 30 hours of build time and were manually abraded and sealed with a two-part epoxy, yielding a surface finish Ra (roughness average) of approximately 0.4µm.

Rock West Composites (West Jordan, UT, US) is collaborating with Stratasys to validate some of the tool designs by molding test parts. Adrian Corbett, director of business development at company, notes the drone industry is incorporating more 3D-printed parts into its products, and 3D-printed tools offer a clear advantage compared to machining tools from epoxy or other tooling materials. “This allows you to make a part as fast as you can print the tool,” he says.

In short, a new drone-prolific era has emerged and is here. Fortunately, for many in the composites industry, change, in this case, is good.

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More