ECO Elise concept: Lean, speedy and green

Focus on use of sustainable materials and cleaner manufacturing processes promises future Lotus customers “almost-guilt-free” performance.

For auto OEMs, race cars and street-legal supercars have provided the “worst-case” testing laboratories in which some of the most valued safety and performance-enhancing features on today’s production passenger cars — airbags, seat belts, antilock brakes, fuel injection, rack-and-pinion steering, all-wheel drive, and bucket seats — were first evaluated. But apart from more efficient engines and lighter weight bodies, these test beds rarely yield environmentally friendly technologies. Lotus Cars (Hethel, Norfolk, U.K.) has taken steps to correct that deficiency with the ECO Elise concept car, a revamp of its popular rear-engine Elise S roadster.

Like its namesake, the ECO Elise features hand-layed composite body panels bolted to an extruded and bonded aluminum frame. It also uses the same powertrain. From the standpoint of tailpipe emissions, the ECO Elise isn’t as “green” as the plug-in electric Tesla Roadster, which Lotus Engineering designed and Lotus Cars builds for San Carlos, Calif.-based Tesla Motors.

Because Lotus already has among the most fuel-efficient cars on the road — its supercars get better mpg ratings than many passenger cars — engineers took a different tack. ”Having already worked extensively on powertrains,” says Group Lotus environmental manager Lee Preston, “we decided to focus on the environmental benefits of using sustainable materials. This is why the ECO Elise promotes a different perspective on ‘green’ — one not directly tied to tailpipe emissions, but rather looking at the materials in the building process.”

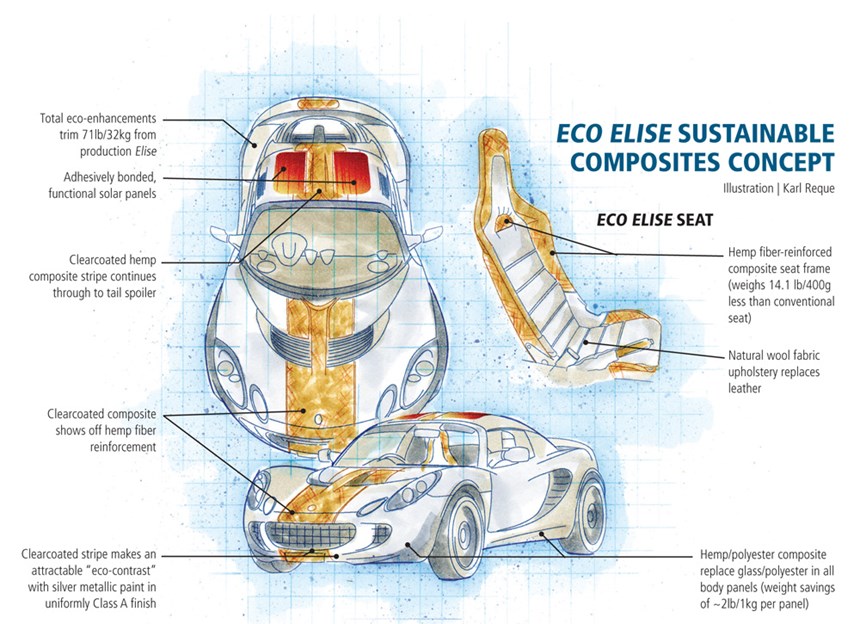

Why brown is the new green

The most visible difference between the ECO Elise and the Elise S is the brown accent stripe of hemp-reinforced composite that starts at the front bumper fascia/clamshell and sweeps up across the hood/bonnet, over the roof and the roll bar cover and then down across the spoiler. The exposed hemp fibers in the stripe — an eco-warrior’s equivalent to visible-weave carbon fiber — signals immediately that this car is different.Lotus swapped out its typical fiberglass reinforcements for hemp in the composite body panels, the double-curvature fixed hardtop and the spoiler. Annually renewable, carbon-sequestering and affordable, industrial hemp (which is not psychoactive) has been used for millennia to produce products as diverse as rope, sails and apparel. Its properties — high-strength, toughness, durability — are among the best of today’s natural fibers, and the energy required for its conversion is low. The use of hemp in place of glass reduced the weight by 2 lb/1 kg per panel at the same nominal wall thickness because of the natural fiber’s lower specific gravity.

The hemp composite also forms the lightweight seats, each now 14.1 oz/400g lighter than its same-sized predecessor. (The ECO Elise also showcases ethical/eco-friendly materials in noncomposite applications. See the “Toward a Total Eco-solution” sidebar, at the bottom of this page).

Although the matrix used in most of the hemp composites is the same unsaturated polyester used in Lotus production car bodies (supplied by Reichhold Inc., Research Triangle Park, N.C.), the company is reportedly seeking a recyclable (melt-reprocessable thermoplastic) alternative. Notably, the company says the same tooling and process steps used to mold standard fiberglass parts were used to produce the hemp composites. Most body panels were vacuum bagged/autoclave cured to achieve good consolidation and low weight, but more complex parts, such as seats and front access covers, were resin transfer molded (RTM) using matched metal tools in a hydraulic press.

Significantly, the hemp-composite seats were subjected to the same internal testing protocol used to validate conventional seats and passed with ease, demonstrating hemp’s potential value as an automotive material. Although no crash testing has been done to date, the underlying crash structure, which manages the bulk of the energy, is identical to that used in the Elise S.

Cleaner, greener, lighter

Beyond the body, Lotus looked at the overall environmental impact of vehicle production and ownership from two perspectives:- Process — creating cleaner manufacturing practices, using sustainable materials, increasing recycling, and reducing the carbon impact of logistics.

- Performance — using renewable energy during production and in use, reducing vehicle mass to improve fuel economy, and promoting more fuel-efficient driving techniques.

“Fuel efficiency is probably the most important factor in greening the road,” Group Lotus CEO Mike Kimberley acknowledges, “but we mustn’t forget how we are making these vehicles. With tens of millions of cars manufactured annually, production also has a huge impact on the environment. Mindful of this, we have taken a holistic approach by focusing on how it is made as well as how it performs.”

As Preston explains, “The new green materials we sourced for this car were carefully studied to ensure that each reduces the environmental impact of the vehicle.” For example, Hemcore Ltd. (Halesworth, U.K.) sourced the hemp from U.K. farmers in East Anglia, supplied it in bales of fibers, which were subsequently chopped at Lotus to lengths ranging from 0.3 inches to 2.2 inches (7 mm to 55 mm). Local sourcing reduced the carbon miles required to produce the vehicle. Additionally, component life cycles were analyzed — during production, in use and at end of vehicle life. “The technologies we used aim to lower both solvent and CO2 emissions during vehicle life as well as to reduce energy consumption during manufacture,” says Preston.

Lotus was already carefully managing logistics between its manufacturing and paint facilities at its headquarters in Hethel and its other manufacturing site in nearby Norwich, which reduces energy consumption and emissions as parts are transported through the supply chain. Key suppliers use the company’s Kanban-driven barcode system, and plants reuse durable and disposable packaging multiple times to reduce waste. However, further environmental impact studies led to changes at Lotus, during 2006 and 2007, that reduced consumption of electricity (14 percent), gas (30 percent) and water (11 percent). Moreover, 57 percent of waste from all Lotus operations now is recycled. Additionally, the company is erecting three wind turbines at its test track. When these come online (about 15 months from now), they will power the entire Hethel site, and energy generated in excess of the site’s needs will be fed into the national grid to help power homes in nearby villages.

Lotus extended its eco-reach beyond its walls by incorporating two flexible solar panels from Flexcell UK, a division of VHF - Technologies SA (Yverdon-les-Bains, Switzerland), into the ECO Elise’s hemp-reinforced hardtop. The panels are adhesively bonded to the roof, which features an optically clear epoxy matrix, also supplied by Reichhold, to protect the panels and prevent water ingress. Although the small roof area limits their size, panels are functional and contribute supplemental power to the car’s electrical system.

Another significant eco-innovation used on the vehicle is a complete water-based paint system that significantly reduces solvent emissions and energy consumption during paint bake, leading to lower cure temperatures. Developed through a program with DuPont Automotive Paint & Coatings (Troy, Mich.), the system has enabled Lotus, for the first time, to hand spray a water-based Class A paint finish on a production vehicle. Lotus also claims to be the first automaker in the world to use the low-volume, solvent-free system for primer, color coat and clear coat. The excellent finish achieved on the ECO Elise prompted Lotus to convert paint operations for its production vehicles to this system by the end of 2010.

Overall, eco-enhancements shaved 71 lb/32 kg off the already trim Elise S. At 860 kg/1,896 lb, the ECO Elise achieves a combined rating of 34 mpg (15 km/liter). More impressive, given the project’s comprehensive sweep, Lotus completed research, sourcing and vehicle build in only 10 weeks.

Good news for eco-warriors

The ECO Elise made its debut July 23, 2008, at the British International Motor Show (London, U.K.). There and at subsequent European auto shows, its practical production- and near-production-ready strategies for reducing a car’s carbon footprint have received an enthusiastic public and media reception at a time when, Preston points out, “the automotive industry is focusing on its environmental obligations to reduce CO2 emissions and improve efficiencies.” Lotus has blazed a technical trail that other automakers could follow to similarly reduce vehicle environmental impact.But one question everyone seems to be asking is, When will it be available for sale? Lotus cautions that there is much to do before the ECO Elise is “ready for prime time,” not the least of which is a full evaluation of hemp composite performance under real-world driving conditions.

“The intention from the very beginning of the project was to make a demonstrator vehicle and see how successfully we could integrate the different technologies,” notes Preston. We are delighted with how the vehicle has turned out. We are analyzing whether to take this research program forward and how we can implement some or all of these technologies in our and maybe even our clients’ cars. If we carry out the research and find it successful, there is every chance we will put the car into actual production.”

Related Content

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreJEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreComposites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)