Engineering large-diameter underground pipe

A combination of design and new materials enhances pipe performance without adding cost.

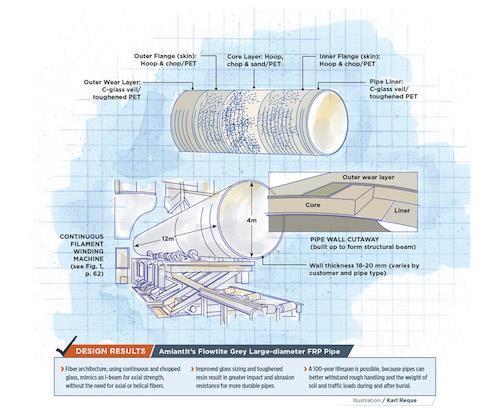

Design Results:

- Fiber architecture, using continuous and chopped glass, mimics an I-beam for axial strength, without the need for axial or helical fibers.

- Improved glass sizing and toughened resin result in greater impact and abrasion resistance for more durable pipes.

- A 100-year lifespan is possible, because pipes can better withstand rough handling and the weight of soil and traffic loads during and after burial.

In the underground pipe market, like most markets served by the composites industry, customers want high performance — in this case, corrosion resistance, great strength and long-term reliability to reduce or eliminate costly repairs — without a high upfront price tag.

That makes good design essential. And that begins with material selection. As is the case in most markets, the traditional materials here — iron, steel, concrete and more recent arrivals thermoplastics — currently rule the large-diameter water and wastewater piping market. That’s because “potential customers using traditional materials today fear that fiber-reinforced plastic [FRP] composite pipes may be damaged during transport and installation underground, possibly because the first cast FRP pipes on the market in the 1970s tended to be brittle,” says Nick Crofts, managing director of pipe manufacturer Amiantit Europe (Mochau, Germany), which acquired Flowtite Technology and its composite pipe design engineers from Owens Corning (Toledo, OH, US) in 2000, after having been its principal licensee.

“We wanted to come up with a new product,” Croft maintains, “tougher than even the best FRP pipes available today, at a comparable or lower price point to these traditional materials.” The goal was a pipe product that, especially in large diameters, “could better withstand in-ground installation and handling — that’s been the Achilles heel for composite pipe.” Toward that end, Amiantit recently introduced Flowtite Grey pipe for water, sewage, waste and raw material management. Envisioned as a way to expand the existing Flowtite product line, Grey would be much more resistant to rough installation and transport practices, better able to handle unexpected debris within the pipe and, especially, able to resist pressure-jet cleaning — a practice typical in concrete, steel and iron pipelines to control slime buildup.

And, it would be engineered to withstand a range of loads imposed by underground burial, which are typically much greater than the loads on a pipe in above-ground installations. “Customers want reliability, especially in remote installations. They’re looking for pipeline lifetimes of 100 years. We were challenged to add safe- guards against the unknown,” adds Crofts.

Designing-in large-diameter durability

“Unreinforced plastic pipe is the benchmark for small-diameter, low-pressure applications, because of low cost, great performance and corrosion resistance. But,” Crofts explains, “plastic pipes don’t work well for large diameters, because wall thickness has to increase proportionally to handle hoop stress, and they become very heavy.” At diameters greater than 400 mm, FRP pipe can be less expensive than plastic or ductile iron, yet deliver better corrosion performance, good flow characteristics and lighter weight for easier shipping and onsite handling. To accomplish this, the properties of the produced FRP pipes often vary. Because each project’s design is unique, based on installation-specific pressures, pipe stiffness class, burial depth, in-pipe vacuum, and handling, each is built to provide the necessary performance but also minimize cost.

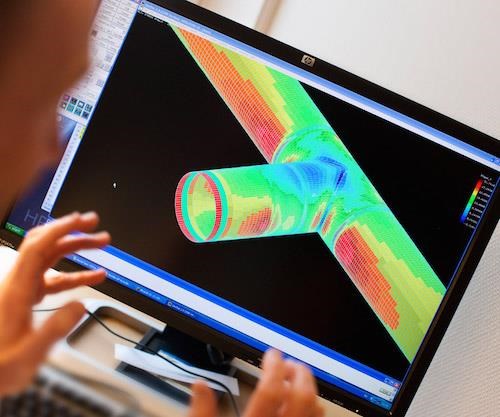

Grey pipe designers, therefore, employ the American Water Works Assn.’s (AWWA, Denver CO, US) widely used guide, titled Fiberglass Pipe Design (Manual M45). “Manual M45 gives the highest safety factors of all the FRP standards, and was our design basis,” says Crofts. Its design equations take into account the velocity and pressure of the conveyed fluid, head loss due to turbulent flow, water hammer, buckling pressure and surge pressure. Flowtite’s application engineering manager, Thomas Hoffmann, adds that additional calculations are required to cover site-specific design conditions, including loads from soil type and depth, traffic loads, backfill type, ambient temperatures and whether the pipe will be restrained by the backfill or require thrust blocking to prevent pipe movement after burial (see other CW coverage of underground pipe challenges in "Editor's Picks," at top right).

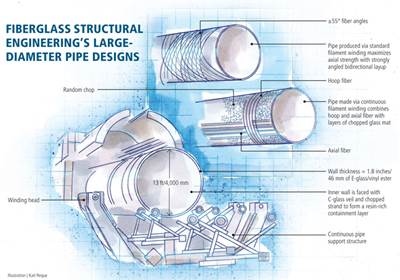

The customer’s optimized design is produced on Flowtite’s continuous filament winding machinery, a technology with a long history (see the Side Story titled Continuous filament winding: A short history," appended at the end of this article, or click on its title under Editor's Picks"). Customizable to a range of pipe diameters, its cantilevered, horizontal rotating mandrel is made up of longitudinal beams fitted with small, outward-facing roller bearings, a series of discs (sized to the pipe to be produced) that support the beams, and a steel “band,” or endless loop (Fig. 1, at left). As the mandrel rotates, the steel band, which is about 51 mm wide, is wound over the beams, hoop-wise, by a placement head on the mandrel’s supported end. As it is wound, the band also is pulled and, therefore, moves over the roller bearings in the axial direction, advancing toward the other (open) end of the mandrel. At that end, an exit head directs the band back through the mandrel’s core to the supported end, where the placement head directs it onto the beams again. In this way, the wound band forms a continuously advancing, smooth tool surface onto which the pipe materials are applied, via filament winding heads on both sides. The wound pipe is pulled along by the advancing band through a heated zone near the mandrel’s open end to cure. Then the cured pipe exits the mandrel system and is cut to the desired length. The technology can wind pipe to 4m in diameter.

Crofts explains that, in common with standard Flowtite pipe, the Grey wall structure is, in essence, a structural I-beam, built up in layers as the pipe mandrel continuously advances (Fig. 2). After a polyethylene terephthalate (PET) release tape is applied, the first layer placed onto the mandrel is a corrosion-resistant, boron-free fiberglass veil supplied by Owens Corning, wet out with a toughened PET. “This forms the essential resin-rich, corrosion-resistant pipe liner, and the toughened PET gives the performance to resist pressure jet forces,” adds Croft.

Over the liner are placed continuous glass rovings wet out with PET resin, in the hoop direction, together with chopped glass rovings that are sprayed simultaneously as the hoop fibers are applied, to form the beam’s inner “flange.” Crofts says the continuous hoop fibers provide hoop strength for pressure resistance, while the chop, although discontinuous, yields required axial strength. In some design cases, the chop can be oriented axially for greater resistance to axial contraction forces, as required.

The pipe wall’s “core” or center is a mixture of a fine-grained sand filler and chopped fiber, resin and more hoop fibers. Next, the outer “flange” is formed like the inner, with hoop and chop. Finally, another boron-free C-glass veil impregnated with the toughened PET forms the pipe’s outermost wear layer, providing a resin-rich protective seal.

“This fiber architecture gives maximum stiffness for the least amount of premium material,” asserts Hoffmann. “For projects where additional performance is needed, we can easily increase the thickness of any element for the desired property translation.”

Flowtite Grey can accommodate operating pressures as high as 32 bar and is offered in stiffness (SN) classes of 2,500 to 10,000 or greater (the larger the SN value, the greater the pipe’s resistance to deflection imposed by soil and traffic loads). Wall thickness, stiffness and diameter are tailored to the customer’s application. Large-diameter pipes are typically delivered in 12m lengths, while “rockers,” used to connect access points, such as manholes, are cut to shorter lengths (Fig. 3).

Material improvements

Ultimately, Flowtite Grey’s greater durability also owes much to materials research. Owens Corning undertook an initiative in 2015 to improve its fiberglass products for piping manufacturers, and spent more than a year benchmarking changes to glass sizing (see "Fine-tuning Fiberglass: Smart fiber sizing," under "Editor's Picks"). Bryan Minges, global product manager for Owens Corning's composite solutions business, says that the silane-based sizing on its new PipeStrand M6000 roving plays an important role in Flowtite Grey’s superior mechanical properties: “Because the new sizing formulation allows a better bond between the glass and the resin than our previous pipe product, fabricators can use less resin to achieve the same part properties. That helps them get cost out.”

“The sizing and its compatibility with the resin is the key to the long-term performance of the Grey product,” adds Crofts. “While we have many fiberglass suppliers, Pipestrand gives us good performance for the cost.”

Flowtite Grey’s improved performance has been verified in tests conducted by Flowtite Technology’s R&D lab, in Sandefjord, Norway. Impact performance was measured via drop testing in accord with industry standards, and in some tests using heavier weights and longer fall heights than the standards. The tests showed no leaks after impact during sustained pressurization, at 1.5 times design pressure for 168 hours. Ultimate burst pressure was 75.6 bar. Says Crofts, “We’ve shown a 60% increase in abrasion resistance and a four- to 10-time improvement in impact resistance than original Flowtite FRP pipe, at a similar price point as competing materials, thanks to the design and materials used.”

The improved impact resistance means a customer can backfill with soils with heavier concentrations of gravel or mixed gravel/ sand, without damaging the pipe, he adds. And, the company’s calculations of a 100-year pipe life are based on accelerated strain data consistent with industry standards, including buried pipe longevity data collected by Utah State University’s (Logan, UT, US) Buried Structures Laboratory.

Because Flowtite Grey was launched in April of this year, customer build specifications are still in progress. Amiantit Germany currently has 10 km of pipeline projects on the books, with installations scheduled for the end of 2016 or early 2017. “A credible pipe product has to address market demands,” concludes Crofts. “Flowtite Grey has been engineered to add security against the very rigorous conditions of large underground piping, for a long service life in a cost-effective way.”

Related Content

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRead Next

Fine-tuning fiberglass: Smart fiber sizing

Some insights into those proprietary chemistries that can customize performance at the fiber/resin interface.

Read MoreDesigning for high pressure: Large-diameter underground pipe

Careful analysis is needed to ensure success of buried composite piping for industrial applications.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More