Fastener-free, composite aircraft door and control surfaces

All-composite, integrated structures using RTM cut weight and cost by more than 30%.

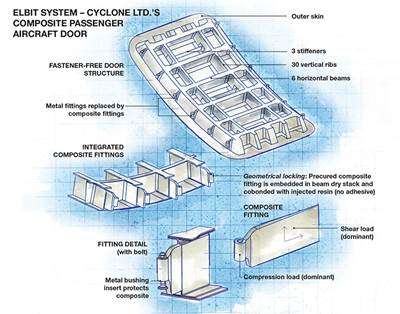

As reported in the High Performance Composites magazine article, “Cutting the cost of integrated composite aerostructures,” Cyclone Ltd. (Karmiel, Israel), a subsidiary of Elbit Systems – Cyclone Ltd. (Haifa, Israel), has developed an all-composite passenger aircraft door that uses no metal fasteners and is made in a one-shot, resin transfer molding (RTM) process.

Cyclone reports it has successfully demonstrated the manufacture of this door design, using its patented, geometrically-locked, composite fittings to achieve a totally fastener-free structure, as well as a 30% reduction in weight and cost vs. similar-sized aluminum and “black aluminum” composite doors in use today.

Cyclone developed the patented fittings in order to replace metallic fasteners used in bonded joints to satisfy regulatory requirements. The issue is that catastrophic failure of doors would jeopardize safe flight, thus they are considered flight-critical or primary structures in aircraft. All primary structures which use adhesively bonded joints must provide redundancy in that load path in case the bonds fail. Thus, most primary composite structures today either use only mechanical fasteners or use them to meet redundancy requirements in addition to bonded joints. However, they require significant post-fabrication machining and assembly, and also add weight because laminates must be “beefed-up” to accommodate the fastener holes throughout without weakening the structure.

Cyclone displayed the integrated, all-composite door at JEC World 2016 (Mar. 8-10, Paris, France).Now that Cyclone has demonstrated the efficient manufacture of this door, it will proceed with cyclic pressurization tests to simulate the in-service life and mature nondestructive inspection (NDI) methods that have been developed.

Integrated Composite Control Surfaces

Meanwhile, Cyclone has extended this technology to integrated composite control surfaces for aircraft (see Technical Paper). As a demonstrator, Cyclone redesigned and fabricated a 1200 mm root segment of an outer aileron for a Heron-TP class unmanned aerial vehicle (UAV) that Cyclone developed and manufactured from 2005 to 2012. The chord of this segment varied from 280 mm at the root to 250 mm outboard and had a maximum height of 47mm.

The baseline composite aileron comprised a cored upper skin and lower skin, a monolithic main spar, six front ribs and three aft ribs, all autoclave-cured, as well as a kit of three aluminum fittings and their supports.

The new structure featured a single integrated skin stiffened by a three-spar array to eliminate ribs and designed to optimally withstand torsion, which is the dominant load. Pre-cured composite fittings made from out of autoclave (OOA) carbon fiber/epoxy prepreg were placed between the dry preform layers to achieve geometrical locking for redundancy and withstand flatwise tension loads. This damage tolerant design aimed to improve the aileron’s durability and reliability. A key aspect was to minimize parts, the derived number of interfaces and the number of holes, and for the composite layers to be continuous as much as possible.

A minimal number of standard materials were used, and core was eliminated, to reduce cost. Advanced RTM injecting liquid resin at high-pressure was chosen to produce a high-quality, integrated structure that is de-molded near-net shape with high repeatability and reduced cost compared to classic prepreg processing.

Feasibility testing, including standard engineering and FEA load analyses, physical tensile, bending and torsion loading, fitting pull-out tests, adapted and validated NDI and production cost analysis has shown this approach successful. Twenty (20) aileron root segment parts with composite fittings were manufactured and tested, successfully demonstrating:

- Fiber-to-resin ratio of 50% by volume;

- Dimensional deviation of ±0.3 mm;

- Weight of 1600 g with deviation of 1.5%;

- No porosity or delaminations in micrographs;

- Lead time reduction of 50%;

- Cost reduction of 35%.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MorePlataine unveils AI-based autoclave scheduling optimization tool

The Autoclave Scheduler is designed to increase autoclave throughput, save operational costs and energy, and contribute to sustainable composite manufacturing.

Read MoreVIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MoreRead Next

Cutting the cost of integrated composite aerostructures

A unitized all-composite aircraft door concept is realized in one shot with no fasteners.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)