Cutting the cost of integrated composite aerostructures

A unitized all-composite aircraft door concept is realized in one shot with no fasteners.

Design Results:

- Maximum structural weight of 35 kg/77 lb (a 30 percent reduction) and a 25 to 35 percent cost reduction vs. comparable aluminum and “black aluminum” designs.

- Simplified manufacturing and reduced cost through the use of standard, low-cost materials and standardized layups in all door frame beams and ribs.

- Higher specific stiffness than a same-sized aluminum door, with a maximum outer skin deformation of 2 mm/0.08 inch under operating load.

Airbus and Boeing commercial aircraft use plug-type fuselage doors designed to employ the pressure difference between the aircraft’s interior and exterior, rather than a locking mechanism, to keep the door closed. Greater pressure within the aircraft cabin forces the wedge-shaped “plug” into its opening, creating a good seal and preventing it from opening until the pressure is released.

For a decade, aircraft door manufacturers have pursued a lightweight, unitized, all-composite alternative to metal plug doors. Two have come close. An “all-composite” door was produced in 2012 for the Airbus A350 XWB at Eurocopter’s Donauwörth, Germany, facility. And in 2011, Latécoère (Toulouse, France) introduced an integrated door, processed as a monocoque via resin transfer molding (RTM).

Although Latécoère and Eurocopter do unify the door’s outer skin with an integrated structure of beams, ribs and stiffeners, each falls short of the all-composite goal. One reason is regulatory. Despite their complexity, truly all-composite doors could be common if exclusively bonded joints were permitted for the principal load path. But aircraft doors are primary structures and, therefore, certification requirements mandate load-carrying redundancy in such joints, achieved most commonly via mechanical attachments. Accordingly, both doors use metallic attachment fittings, which require significant post-fabrication machining and assembly.

Another reason is daunting complexity. Although it is nearly fastener-free, the Latécoère door features a complex preform that must be assembled on a special tool from 45 separate and complex subpreforms, all of which must be robotically stitched together prior to the molding cycle (see “Integrated, optimized aircraft door,” under "Editor's Picks," at top right). Moreover, its complex corner structures are molded separately.

Against this backdrop, Cyclone Ltd. (Karmiel, Israel) unveiled a design concept (see end note) that simplifies and reduces the cost of integrating door components, using a true one-shot molding process. It does so without the use of metal attachment fittings or separately manufactured and riveted composite outer frames.

Simply fastener-free

A subsidiary of Elbit Systems (Haifa, Israel), Cyclone has built aircraft doors since the 1980s, currently manufacturing more than 170 per month for a variety of commercial platforms. R&D manager Lior Zilberman describes the project’s inspiration: “The challenge for composite structures now is to reduce cost. We sought to demonstrate composite primary structure without mechanical fasteners because this allows composites to be used most efficiently. Fasteners increase labor, cost, weight and complexity.”

Cyclone developed a Type A plug door, which fits a 6m/19.7-ft diameter (Boeing 787-like) fuselage. It comprises a nominal 5-mm/0.2-inch thick outer skin with 150-mm/5.9-inch-deep integrated frame elements, including six horizontal beams, 30 vertical ribs and three stiffeners. Zilberman and this project’s design leader, Oran Katzuni, say this configuration provides the best cost/performance/weight ratio.

To cut cost, Cyclone avoided exotic materials and extra steps, such as stitching. Instead, a few standard aerospace materials were used: 3K plain-weave dry carbon fabric (195 GSM/PW/T300B) from Sigmatex Ltd. (Cheshire, U.K.); a copper/tin alloy wire mesh for lightning strike protection; and 12K T700 375 g/m2 (11 oz/yd2) carbon fiber unidirectional tape, supplied by Eurocarbon (Sittard, The Netherlands) for spar cap reinforcement on the beam flanges.

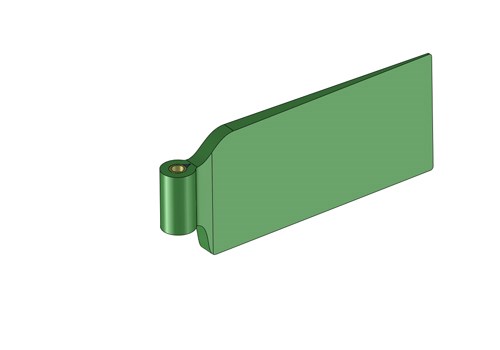

Processing was simplified by “using one standardized layup in all of the beams and another standardized layup in all of the ribs,” Katzuni adds (see third image). “This minimizes the risk of mistakes during manufacture and lowers cost. Also, only minimum preform layers are required thanks to our optimization analysis.”

That analysis involved the somewhat new technique of first performing a composite free-size optimization (a topology optimization of the finite elements) and then a composite size optimization, which defines the number of plies in specific layup directions to meet design targets. “Previously, FEA optimization was based on zones, where each zone has its own optimized layup. Composite free-size optimization is done per each element, identifying what is the best thickness for each fiber orientation,” Katzuni explains, noting that during subsequent composite size optimization, manufacturable continuous patterns were identified and optimized and cost analysis applied. He sums up, “This gave us the opportunity to evaluate different failure modes so that each laminate stack was optimized throughout the door structure for minimum plies and maximum efficiency.”

The door frame corners, however, presented a unique challenge to full integration. Their complex geometry is likely the reason Latécoère chose to compression mold them from carbon fiber/polyphenylene sulfide instead of forming them with the rest of the door. “We succeeded,” says Zilberman, “in developing a mandrel that formed the complex shape — even with standard carbon fiber plain weave, which has limited drapeability.” The team developed a dry preform layup technique that avoided wrinkles and edge peeling and then tested the preform’s wettability via resin infusion.

The analysis took more than a month, but it was the key to cost-effective materials use. The CAD programs included CATIA V5 (Dassault Systèmes, Vélizy-Villacoublay, France), with the Composites Product Design module, and HyperMesh for preprocessing and OptiStruct for composite optimization, both from Altair Engineering Inc. (Troy, Mich.). MSC NASTRAN (MSC Software Corp., Santa Ana, Calif.) was used in the final FEA.

Early on, Cyclone consulted with the engineering director at El Al Airlines (Jerusalem, Israel), who warned that the door is exposed to much impact during its life, including barely visible impact where delamination can be hidden. Zilberman recalls, “He cautioned us to pay attention to this and try to use an impact-resistant configuration.”

Here, Cyclone used a damage tolerant layup and a unique toughened epoxy. Typically, toughening is achieved by adding small elastomeric polymer particles that enable significant fracture energy absorption. But, Zilberman points out, “The carbon fabric behaves like a mesh, stopping the dispersion of the particles during RTM.” So Cyclone selected Huntsman Advanced Materials’ (Everberg, Belgium) XU3508 resin system, which uses “multiphase toughening technology” that is not screened out during injection. Curable at relatively low temperatures, the resin’s gel time allows preform wetout before viscosity increases.

Integrated composite fittings

Cyclone replaced the typical titanium attachment fittings with precured monolithic composite fittings made from Park Electrochemical Corp.’s (Melville, N.Y.) 193g/m2 (5.7 oz/yd2) out-of-autoclave (OOA) E752 epoxy/3K carbon fiber HTPW (high-tenacity, plain-weave) prepreg. It’s currently undergoing equivalency testing against qualified materials at the National Center for Advanced Materials Performance (Wichita, Kan.).

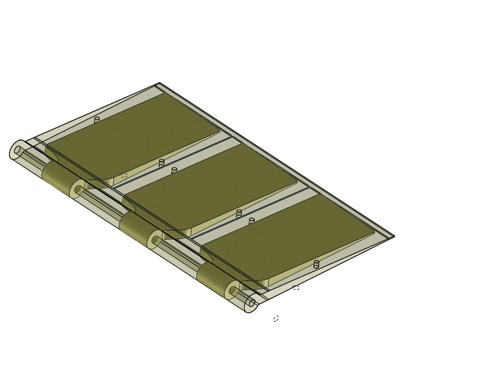

To minimize cost, multiple fittings are produced from each panel (see images below). Prepreg layers are automatically cut then manually placed in a matched metal die for cure at 121°C/250°F. Fittings are cut and trimmed from demolded panels and then ultrasonically tested.

A slot designed into each end of the beams (see initial image), enables Cyclone to embed fittings between the preform plies — geometrically locking them within the door beams (pat. pend.) — and then cobond them with the door structure. “Our fitting is capable of transferring redundant multidirectional loading, although it mainly acts to convert shear load from the door beam to compression load in the fitting head,” Zilberman says. “We have verified this capability through testing, which loaded the fitting subassembly in compression, as it would be in service.” It exceeded the ultimate design load by 50 percent without failure.

True one-shot process

The RTM tooling was developed in-house. PAM-RTM (ESI Group, Rungis, France) was used to optimize injection and vacuum port locations. Multipiece, detachable aluminum mandrels were designed for easy extraction, with locators, layup rails for beam flanges and resin channels for flow control. Cyclone’s special mandrel machining process is accurate to ±0.1 mm/±0.004 inch.

In production, dry materials will be cut, layed out in the lower mold for the outer skin and shaped into preforms for the door frame elements, using the mandrels. After the precured fittings are embedded in the beam preforms, the mold will be closed and resin will be injected and cured at 120°C/248°F. The demolded door will be oven postcured at 140°C to 200°C (284°F to 392°F) for four hours to achieve the wet Tg required for primary structure. Trimmed doors will be inspected ultrasonically and then metal bushings will be bonded inside the fittings to prevent local crushing. Although preform layup was done manually during development, Zilberman claims, “it will be no large step to automate this for future production. Eurocopter uses an automated dry preform line with robots to lay up the fabric on metallic mandrels for the A350 XWB door.”

Savings on the wing (and tail)

Having completed the feasibility demonstration, Cyclone is building production tools for manufacturing and certification of full-scale doors and applying this technology to control surfaces and empennage structures. Cyclone business development director Eitan Cohen concludes, “Our strategy in today’s competitive aerostructures market is to offer improved value by not just meeting high-rate serial manufacturing, but to do so using innovative solutions that achieve high performance and affordable cost.”

Lior Zilberman and Oran Katzuni presented “Development of Monolithic RTM Cost Reduced Composite Passenger Door Structure” at SAMPE 2013 (May 6-9) in Long Beach, Calif.

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

Integrated, optimized aircraft door

This composites manufacturer is betting its one-piece 3-D preform and RTM process will trim weight from today’s fastener-intensive “black aluminum” aircraft doors.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More