Gurit CBS for the Aston Martin DBS

Out-of-autoclave process mints Class A carbon composite body panels in one-hour mold cycle.

At its facilities in Newport on the Isle of Wight, located a few miles off the South Coast of the U.K., Gurit (UK) Ltd. has developed a molding process for its trademarked SPRINT material system that is designed specifically to meet the needs of the customer who wants to cure carbon composite structural parts without the long cycle times and cost associated with the use of an autoclave. The SPRINT prepreg system reportedly cures in less than an hour under vacuum pressure.

Gurit recently set up a lean manufacturing facility to prove the concept’s applicability in the real world by manufacturing five exterior body panels for the Aston Martin DBS sports car. The £2 million ($3.2 million) investment has created a 20,000 ft² (2,000m²) pilot facility capable of molding, machining, assembling and painting as many as 45 car sets per week. I was able recently to visit the pilot plant, observe production and assembly of the Aston Martin components and gather the following project data.

Adapting SPRINT for body panel production

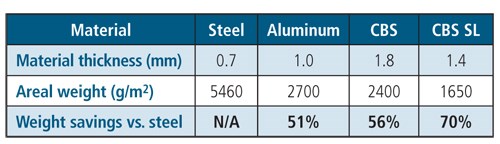

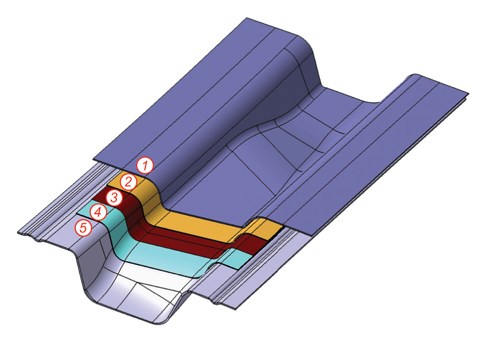

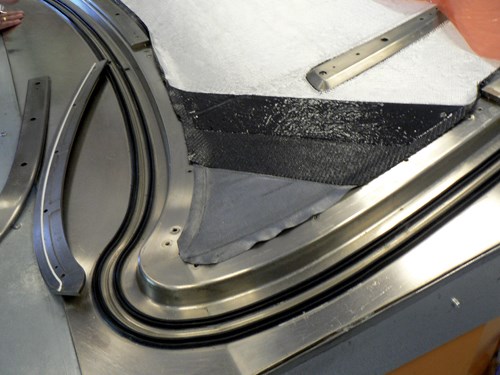

To meet the needs of car designers, Gurit materials engineers introduced two features to the standard SPRINT system that are not normally seen in structural carbon fiber-reinforced polymer (CFRP). For one, they’ve added an outer ply of surfacing film that enables production of parts with a Class-A finish — free from pinholes and fiber print-through — straight out of the mold. The other novel feature is a thin (0.7mm/0.03-inch) layer of epoxy syntactic foam, in the middle of the laminate ply schedule, which improves buckling resistance (see Fig. 1). The laminate system, with core and surfacing film, is called CBS, which stands for “Car Body Sheet,” and is produced at an adjacent Gurit prepreg facility and then delivered to the production shop assembled and ready for cutting and molding, thus significantly reducing the layup time. It is claimed that the system yields weight savings of between 56 and 70 percent, compared with steel, depending on whether the reinforcement is a hybrid of glass and carbon or all-carbon. In the latter case, the material is designated CBS SL (Super Light). The weight data for the SPRINT CBS parts is given in Fig. 3 on p. 26 in comparison with the same parts made with traditional automotive materials.Molding an assembly-friendly second surface

This plant produces the two front fenders, the hood and the trunk lid for the DBS. All feature the CBS system for their outer skin. The hood and trunk lid feature internal stiffening panels, also made made from CBS. (Aston Martin customers have the same high expectations for surface finish on the parts they can see whilst putting their luggage in the trunk or checking the oil level under the hood, as they do when looking at the exterior body panels of their beautiful cars!)Gurit is currently using 35 direct workers on two shifts, with 20 indirect workers who perform accounting, quality-control and manufacturing engineering support functions for this team. The production facility is divided into nine manufacturing cells:

- Kit cutting

- Kit assembly

- part layup and cure

- Inspection, de-flash and paint prep

- CNC trim and drill

- Assembly

- Paint

- CMM inspect

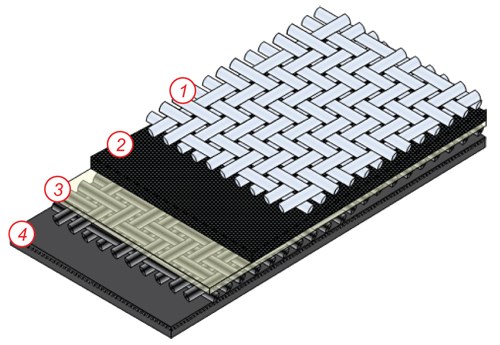

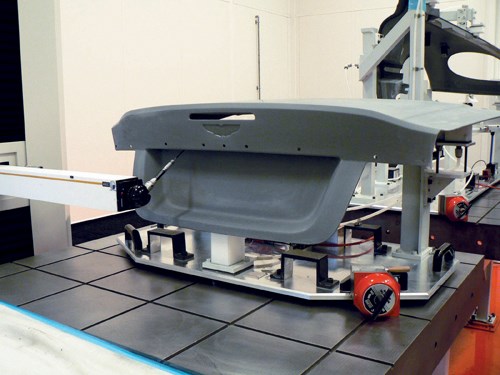

Following kitting and layup, the parts are cured in oil-heated nickel-shell tools (see Fig. 4) supplied by Weber Manufacturing Technologies Inc. (Midland, Ontario, Canada). Parts are layed up and cured under vacuum in one location, thus avoiding the need to move tools around the production shop. All parts are cured with an outside Class-A finish and an inside tooled finish suitable for bonding components, such as stiffeners, to the inside of the hood and boot trunk lid. The high quality of the inner surface is achieved by means of a glass fiber-reinforced caul plate. On parts with a one-piece caul plate, the plate has two functions. It ensures a good, tool surface-like finish, and it also acts as the vacuum medium, avoiding the cost and time required to use vacuum consumable materials, such as reusable silicone rubber bags. On the more complex parts that have multipiece caul plates, a silicone bag is used in addition to the caul plates to seal the entire layup (see Fig. 2, previous page, top right).

Getting the edge on metal parts

One advantage of metal body panels is that the edges can be easily “rolled” to give a nice smooth feel to any edge that the customer is likely to see or touch, such as a wheel arch or trunk lid lip. To reproduce this finished edge, Gurit developed a technique for folding over the edge of the laminate against a loose edge-tooling bar. This achieves the same thick, rounded edge that is achieved in metal panels and also avoids the cost of postmold machining of the edge. The quality of the as-molded edge on the CBS parts is comparable to that on previous metal parts — it looks like a metal rolled edge and is free from resin richness or air bubbles (see Fig. 5).The inner and outer panels of the trunk lid and hood are bonded at room temperature, in complex fixtures, which determine the final shape of the very stiff panel assembly. (See Fig. 6). After this assembly step, all parts are inspected for dimension accuracy on a coordinate measurement machine (See Fig. 7) and then visually inspected for surface finish. Gurit says they have to be right the first time — no repairs are allowed on external surfaces.

The finished parts are primed, then placed in special containers and shipped directly to the Aston Martin assembly line. The parts undergo no further inspection until after they are fitted to the car

Assessing the effect on assembly

At the Aston Martin assembly plant, the CBS parts are integrated into the car’s structure. One of the real tests of whether or not composites have a long-term future in automotive production is their utility here. Automakers balk at new materials or methods if they produce parts that subsequently require special treatment. I saw no evidence of this with Gurit’s CBS parts. Other than their color, the metal and composites parts were indistinguishable in terms of their handling. Aston Martin’s operators seemed unaware of whether the panels they removed from the line-side containers were made of one material or the other. (However, to this observer, one curious effect on the car assembly line was that, before the cars are given their final coats of paint, the Aston Martin is a patchwork of composite panels primed in gray, and therefore looking like metal, and aluminum panels primed in black, looking like CFRP!)The Aston Martin parts project represents a significant milestone in efforts to adapt carbon composites for series production in the automotive environment. Its success in a necessarily unforgiving Class A parts program supports Gurit’s ambition to expand its business into manufacture at higher volumes, based on the lessons learned from this very impressive pilot plant.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreRead Next

Carbon car hood: Class A and cost-effective

Resin film infusion, electroformed nickel tooling meet Aston Martin quality and cost targets.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More