High-speed, 3D winding of large, complex-shaped composites

Cygnet Texkimp is translating decades of fiber-handling and processing know-how into machinery that opens new opportunities for composites manufacturing.

Share

Cygnet Texkimp (Northwich, UK) is a global manufacturer of specialist machinery to handle and process advanced fibers and fabrics for the automotive, aerospace and wind energy industries. It provides end-to-end service from design through after-sales support, using in-house specialists in automation, robotics, software and electromechanical design, and is quite accustomed to meeting complex technological demands.

The company draws from its long history in textiles — Texkimp was founded in 1974 — and its current position as part of the Cygnet Group’s diverse collection of engineering-based companies providing bespoke, high-performance solutions to global markets.

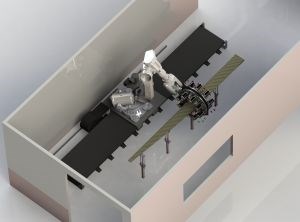

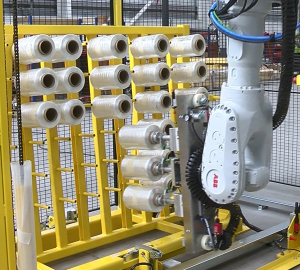

Cygnet Texkimp produces a wide array of customized machinery for composites, including automated material handling systems. SOURCE: Cygnet Texkimp.

Cygnet Texkimp products include compactors and laminators, creels, fiber spreaders, tape and fabric slitters, prepreg lines, material handling solutions and much more. “We’ve been a key supplier of prepreg machinery supporting major aerospace contracts for the last five years,” says Cygnet Texkimp managing director Luke Vardy, “but because we have not been at liberty to talk about these successes, the composites industry doesn’t have a full understanding of our competency.” Now, however, the company has been able to dedicate resources to its own R&D, building new machines to its own specifications. “Our focus is on the fiber, how to enhance its properties and make the most of it,” says Vardy.

SOURCE: Cygnet Texkimp

High-speed, complex 3D winding

One example of Cygnet Texkimp’s new initiatives is the robotic, high-speed 3D winding machine it has developed for producing complex-shaped composite parts. It is based on a 9-axis robotic winding concept originally developed at the Northwest Composites Centre at the University of Manchester (Manchester, UK) and is designed to lay down multiple tows at once, each tow as large as 50k if desired. “By mounting the winding mechanism onto a rotating axis, we can follow complex curves and wind multiple fiber ends around corners,” says Vardy. The dry fibers are wound at high speeds — e.g., 1 kg/min — layering to build 3D preforms that are infused with resin to produce composite parts.

Carbon fiber composite tube made with Cygnet Texkimp 3D winding technology. SOURCE: Cygnet Texkimp

One example of how this can be applied is the fuel feed hose for aircraft such as the Airbus A380. “These are currently made by welding multiple sections of titanium pipe, which makes them prone to leaks” Vardy explains. “We can wind the complex 3D shapes while building in more hoop strength, producing a higher-pressure hose which does not leak and dramatically improves aircraft maintenance,” he adds, noting this composite fuel feed line is produced at a fraction of the cost and time vs. current metallic versions.

Another potential application is automotive cant rails. Also called roof rails, these are the longitudinal side members which run from the trunk to the hood over the doors and to which the roof is attached. They are key strengthening members in a vehicle but also have a complex arc shape. “We can wind these in one piece and increase thickness locally where needed, such as where the A pillar and B pillar are joined, by simply winding more fiber in that area,” says Vardy.

“We could also wind a bridge arch or a whole wind turbine blade,” he adds. But isn’t fiber winding too expensive for construction and wind energy applications? “What are the alternatives,” asks Vardy, “hand layup with large swaths of fabric? It is cheaper to wind on top of a CNC-machined foam mandrel. The speed at which we are laying is much faster than braiding, for example.”

|

Cygnet Texkimp’s high-speed, 3D winding technology exploits the company’s expertise in fiber handling to revolve the creel around the part, yet is able to efficiently wide large structures like wind blades. SOURCE: Cygnet Texkimp

Vardy points out that this fiber handling ability is what Cygnet Texkimp is known for. “We revolve the creel around the part,” he explains. Another benefit of this approach is size. “We can go down to 25 mm,” says Vardy, “or up to an aircraft fuselage. The only limit to the size of what we can wind is that our current robot is designed for a 250-kg payload — i.e., 16 packages of fiber.” This machine currently produces parts up to 10m in length and 0.5m in width.

Vardy notes that this technology also creates, in effect, a multiaxial laminate “because we can vary the angle of the fiber wind during one pass. For example, we can create a low angle of less than 30° and then lock that in with an 85° hoop.

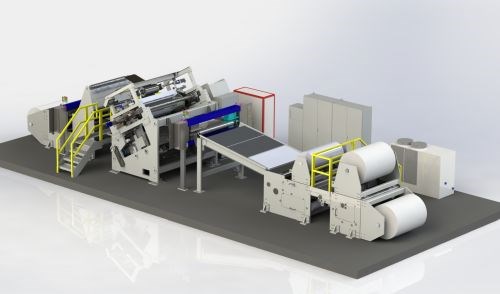

For more details on this technology, visit Cygnet Texkimp at CAMX 2017 (Sep. 11-14, Orlando, FL, US), Booth L87, where Vardy and his team will also have more information on the two new prepreg lines in construction and 50-inch reverse roll coater, which will be delivered by January 2018.

Cygnet Texkimp’s new 50-inch reverse roll coater for aerospace prepreg will be installed early in 2018. SOURCE: Cygnet Texkimp

Related Content

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreUpdate: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More