High-Volume Preforming for Automotive Application

More than a dozen parts for four Aston Martin models are mass produced in France using Ford Motor Co.'s optimized Programmable Preforming Process and resin transfer molding.

High-speed, high-rate preforming has been touted for years as the solution for reducing composite part cost. Yet actual examples of production preforming for real-world parts have been few, indeed.

A notable exception is a rapid preforming operation located at Sotira Composites (Saint Méloir des Ondes, France) that represents a technology partnership between Sotira, Ford Motor Co. (Dearborn, Mich.) and Aston Martin (Gaydon, Warwick, U.K.). The three companies have collaborated on a preforming technology that, together with resin transfer molding (RTM), produces nearly 50,000 composite parts per year for Aston Martin's DB9 coupe, DB9 Volante (convertible), V8 Vantage and V8 Roadster models. CT recently had a chance to tour the Sotira plant and technology center and see the process, now known as the Ford Programmable Preforming Process or F3P, in action.

LONG-TERM DEVELOPMENT PAYS PREFORMING DIVIDENDS

"This manufacturing cell at Sotira has taken about 10 years to fully develop," says Ford's manager of the Manufacturing and Processes Department, Ford Research and Advanced Engineering, Dr. Carl Johnson. "It's the largest application of F3P anywhere in the world."Ford, long an advocate of composites, began research into preforming more than two decades ago. Its research into chopped-fiber preforming began in the early 1990s, when the Automotive Composites Consortium (ACC) of the Partnership for the Next Generation Vehicle, sponsored by the U.S. Department of Energy in concert with Ford, General Motors and Chrysler, participated in an effort to demonstrate automated production of a structural composite truck pickup box. The process identified was the "P4" method, for Programmable Powdered Preforming Process, originally developed by Owens Corning Composite Solutions LLC in Battice, Belgium, together with Aplicator System AB (Molnlycke, Sweden). Aplicator System manufactured the automated glass roving chopper gun in this original system.

In the P4 process, glass fiber was chopped and sprayed via a robotic arm onto a screen that was shaped like the part, through which a partial vacuum was drawn. At the same time, a powdered binder was applied, usually at 3 to 5 wt-%. Afterward, the preform was compacted while heated air was passed through the screen, to melt the binder. When the preform was fully compacted, the binder was cooled and solidified by passing cold air through the screen, allowing the preform to be removed from the screen tool and placed into the resin infusion mold.

Interest in P4 was generated by its high degree of automation and very low requirement for touch labor; its capacity for making preforms with complex geometries to near-net shapes; its potential for parts integration, including typically separately molded and secondarily bonded rib stiffeners and other elements; and its ability to incorporate core materials and openings into the preform. P4 technology still exists and has morphed into the Rapid Fiber Preforming (RFP) process now used by the National Composite Center (NCC, Dayton, Ohio). P4 also received further funding from the U.S. Air Force to investigate its feasibility for aerospace parts with chopped carbon fiber (For more on P4, see "Learn More," at right).

Enter Aston Martin, the longstanding luxury performance carmaker, in which Ford acquired a majority stake in 1987. Ford took full ownership of the company in 1994. The company's sales revived during the strong economic conditions of the 1990s, and market demand drove development of several new models, including the V12 Vanquish, introduced in 2001, which incorporated 26 composite components. In addition to RTM-molded, carbon fiber triaxial braids for the car's structural A-pillars and other carbon structural parts, the Vanquish also was a test bed for F3P, Ford's refinement of the original P4 process, which was used to produce preforms for the car's Class A body side panels.

Dr. Ken Kendall, Aston Martin's Advanced Technology Manager, explains that rapid preforming was absolutely necessary to meet the peak production demand of 7,500 automobiles per year on all vehicle lines (including DB9 derivatives) as the company grew: "Senior management at Aston Martin and Ford at that time deserve credit for their belief in F3P — had the technology not worked, we would have had great difficulty expanding our business at the speed we have."

Engineers from Aston Martin and Ford spent months in Sotira's plant to ensure a rapid transition and expansion of the F3P technology used for Vanquish to the larger production volumes associated with the DB9 and V8 Vantage. Kendall says that Sotira's demonstrated expertise — Sotira had made composite components for the Aston Martin DB7 using thermoformed continuous filament random mat (CFRM) — was key to its selection as a technology partner in the F3P commercialization process: "Together, Ford, Aston Martin and Sotira pioneered technology that has shaped our vehicle architecture — we at Aston Martin have expanded F3P part applications to every vehicle line."

Components currently being produced by Sotira for Aston Martin are highly complex, comprising the door opening rings (left and right), decklid surround, decklid and door sills (left and right) on the DB9 coupe; door opening rings, decklid surround, decklid and sills on the DB9 Volante; door opening rings (left and right), tailgate surround and tailgate inner on the V8 Vantage; and door opening rings and decklid surround on the V8 Roadster. Each has a complex shape, with thick/thin transitions, foam core inserts in the decklids, cutouts and comolded metal inserts.

Sotira's general manager, Louis Rouyez, explains that the parts' intricacies made them good candidates for the F3P-RTM process: "Although the F3P represents a large capital investment, in the end it has paid off with much lighter weight components compared to stamped metal parts, lower overall tooling costs, and almost no waste, because we can essentially make net-shape parts with this process."

REFINED ROBOTICS FACILITATE RUNNING AT RATE

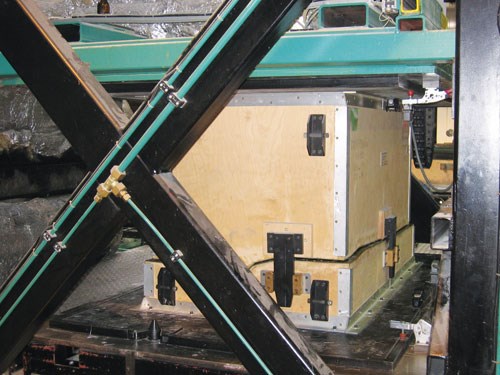

Rouyez notes that it has taken years to optimize the process for efficient rate production. The current setup at the Sotira facility consists of a two-station work cell (see top photo, at right) manufactured and supplied by Aplicator System. A six-axis articulated arm robot on a fixed floor track (the track provides a seventh motion axis) can shuttle side to side between the two fixed preforming stations, each of which has an associated gantry-mounted consolidation die with hot and cold forced air ducts. Thus, as the robot deposits fiber at one station, heating/consolidation/cooling occurs simultaneously at the other station. The entire preforming process requires only a single technician, who oversees the computerized control system and manually removes and stacks the finished preforms.COMMINGLING BINDER/ROVING PREVENTS CLOGGING

A principal reason for the success of F3P at Sotira is the optimization of both materials and the process, based on lessons learned. The missing "P" in Ford's F3P acronym, for example, represents the elimination of powdered binder, says Johnson. "The original concept of powdered binder caused several problems, including significant clogging of the holes in the preform part screens," he notes. "We were able to overcome it by switching to string binder.""String" binder differs from powdered binder in that the thermoplastic poly-mer is spun into fibers, which then are commingled with the glass fibers in the roving. Sotira uses a string binder incorporated into a proprietary roving, called PREFORMance, manufactured by PPG Industries Inc. (Cheswick, Pa.). The polymer fiber makes up 6 to 7 percent of the roving by weight. Because the dry string binder fiber is part of the roving, it chops like the glass and disperses evenly, unlike the previous powder, which required a separate application stream and led to inconsistent fiber/resin mix (see "Learn More"). Steve Morris, senior R&D project engineer at PPG, says that microscopic studies of PREFORMance show that when heat activated, the thermoplastic fibers adhere to the glass fibers only at small discrete contact points, like a fine spider web, and, therefore, don't interfere with the final resin/fiber bond during RTM molding.

Other improvements have been made to the chopper and the fiber handling system, says Rouyez. The robot's speed and constantly changing gun orientation require consistent roving tension and support to prevent uneven fiber feed or tangling. His crew has developed a creel and glass roving feed setup that works well with the chopper gun, he reports. Also under development is a chopper gun and feed system for carbon fiber-reinforced parts.

To make a typical Aston Martin part, such as a door opening ring, the robot moves to one of the two preform stations, which consist of fixed, raised bolsters or platforms that support perforated female epoxy (or metal) preform screen tools. The robot begins by first chopping a fine, 1,200 tex low-density veil roving supplied by Owens Corning Composite Solutions LLC (Toledo, Ohio), without any binder, into portions of the tool where a good surface finish is required. (A pressure drop across the screen tool holds the fibers in place on the screen, with very little waste or scatter.) The veil also helps in demolding of the preform from the tool, says Rouyez. Then, two ends of 3469 tex PPG PREFORMance roving are chopped over the entire tool at fiber lengths of about 1 inch/25.4 mm.

A key feature of the F3P system is that preform thickness, and to some extent, fiber orientation, can be varied to meet the part's design requirements, placing the fibers where necessary without wasting material by spraying beyond the part edges. Fiber length also can be adjusted on the fly, says Johnson: "The machine and the process are flexible and tailorable to the application."

When the robotic chopping is complete and the robot has moved sideways to the other preform station, the moving gantry that supports and operates the matching male screen tool moves forward — on rails oriented perpendicular to the robot rail — and into position over the preform. The die moves downward, enclosing the prepared preform. Hot air is delivered to the die through large ducts that enable very rapid heating of the preform and subsequent melting of the binder polymer. Hot air is immediately replaced with cold air to set and cool the preform. The top die moves upward, the gantry retreats and a technician removes the completed preform. The entire heat/cure/cooldown cycle takes only minutes to complete. Rouyez points out that preform screen tools can be changed out quickly, as dictated by the production cycle, and replaced with other tools, which are stacked on forklift-accessible racks behind the work cell.

Each completed preform is numbered and identified with a printout from the computer's numerically controlled workcell software. Completed preforms are stacked and stored on wheeled carts for transfer to the RTM molding area in another part of the building. There, six 350-ton presses mold the preforms in an RTM process, using a one-component, precatalyzed, low-profile polyester resin supplied by Scott Bader Co. Ltd. (Wollaston, Wellingborough, U.K.). For a V8 Vantage tailgate inner (a combined sandwich and single skin structure) one preform is placed on the chromed steel tool face, followed by a prefabricated closed-cell foam core insert, produced to specification by a sister company within the Sora Group, explains Rouyez. The injected foam insert contains an embedded steel plate for subsequent fastener assembly. After a second preform is placed over the insert, the tool is closed. The tool is made with a central injection port and resin runners around the periphery, says Kendall, and was analyzed by Aston Martin and Ford using PAM-RTM software supplied by ESI Group (Rungis, France). Mold fill time is approximately three minutes, and total mold close time is anywhere from 18 to 20 minutes. Peak injection pressure is about 8 bar/115 psi. The mold is heated to a temperature of approximately 120°C/248°F.

Kendall explains that the tailgate inner is subsequently bonded at Aston Martin to the tailgate outer to produce a two-piece tailgate assembly weighing 11 kg/24 lb, which replaces an equivalent 10-piece conventional metal assembly that weighs about 15 kg/33 lb.

FORCE-SENSITIVE SANDING HEAD KEYS HIGH-END FINISH

After demolding, the parts are sanded in a robotic cell manufactured by Belotti SpA (Suisio, Italy). The primary reason for the sanding, says Rouyez, is to remove any remnants of mold release agent, which can interfere with bonding of the parts. The sanding work cell consists of an articulated arm robot inside a glass-enclosed workspace that minimizes noise and dust. A rotating two-position table allows a part to be set up outside the cell by workers while a second part is sanded inside; when the sanding cycle is complete, the table brings the finished piece out while the unfinished piece is rotated inside to the robot, greatly increasing productivity. The robot, supplied by ABB Ltd. (Oerlikon, Switzerland), is equipped with a force-sensitive head that applies just enough pressure to lightly sand the contoured surface of the complex parts. A second robotic work cell, also supplied by Belotti, enables automated deflashing and drilling of fastener holes and cutouts in the same fashion.Quality control checks are conducted periodically to maintain dimensional control on the parts. A large coordinate measuring machine (CMM) from Metrolec CMA (Argenteuil, France) measures more than 30 registration points on selected parts and compares them to the CAD file to ensure good part fit at Aston Martin. A FARO Technologies Inc. (Orlando, Fla.) measuring arm also is used to check part compliance.

The final step is priming of the parts, which takes place in a separate building in a manual paint line (shown in the photo marked Step 12), which is maintained at 50 to 70 percent humidity for optimal bonding of the primer to the composite, explains Rouyez. The primed part provides the opportunity for a final visual surface quality check before the parts are shipped to Aston Martin.

"Aston Martin engineers have become experts in designing components that are suited to this process, and this is key to the success of the F3P technology implementation at Aston Martin," Kendall concludes. "We have embraced a number of composite technologies, of which F3P/RTM is the most prominent, in all of our vehicles."

Related Content

Noble Gas Systems 350-bar conformable pressure vessels pass HGV2 standard tests

Conformable tanks with new materials pass technical tests for hydrogen storage, to compete with Type IV pressure vessels using CFRP.

Read MoreCorebon, Composite Braiding partner to enhance TPC manufacturing

Collaboration aims to overcome production limitations with tubular thermoplastic composites (TPC) by using induction-heated tooling and high-quality commingled braids.

Read MoreCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More