Hybrid composite struts reduce vehicle weight, improve handling

Pultruded carbon/glass fiber composite underbody stiffeners move into medium-volume Mercedes-AMG production vehicles.

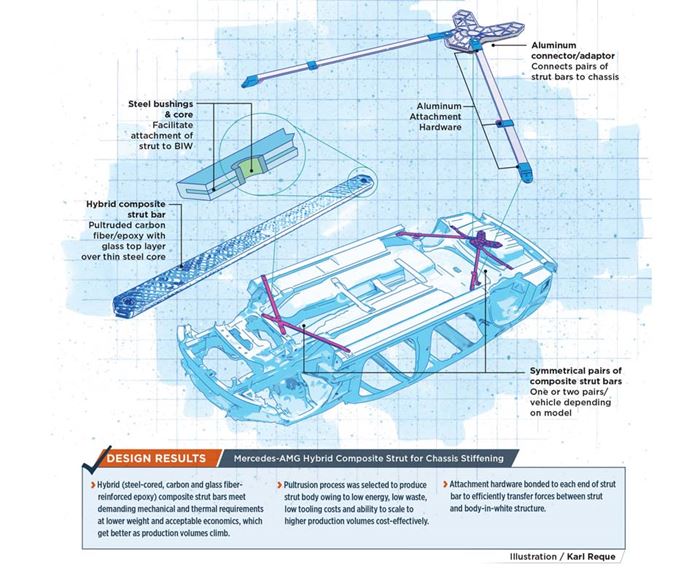

A joint development team from Daimler AG’s (Stuttgart, Germany) R&D organization and the Mercedes-AMG performance car division began investigating ways to trim mass cost-efficiently from body-in-white (BIW) structural components. An early target (circa 2011) was pairs of all-steel strut bars on various performance-vehicle models — one pair on some vehicles; two pairs on others. Functionally, the struts increase vehicle rigidity and improve handling.

Strut bars — usually inexpensive compressed steel tubes — are well established on production vehicles. Already well optimized in terms of cost and weight, these benchmarks provide limited opportunities to improve either in the incumbent steel format. But composites — particularly in the form of carbon fiber-reinforced plastic (CFRP) — offered new opportunities to lightweight the struts, yet meet demanding mechanical and thermal performance, while also keeping the economics reasonable.

Issues with conventional strut bars

Chassis strut bars are structural components designed to resist compression and tension in the longitudinal direction by providing outward-facing support along each bar’s longest axis, thereby holding two components apart and preventing them from flexing or collapsing. Correctly designed and installed, strut bars help stiffen substructures. The practical result is a reduction in chassis flex as vehicles cross uneven surfaces or take tight corners, experienced as improved vehicle “handling” for drivers.

Although several higher performance metals (e.g., titanium) were considered to replace traditional steel struts, they were eliminated because they would add cost but could not meet all of the mechanical requirements for the desired lightweight design. The team then turned to CFRP. “Struts are used frequently in the substructure or front section of vehicles to rigidify the body shell and optimize the driving characteristics in terms of comfort and sporty handling,” notes Jörg Miska, head of body development, Mercedes-AMG. “CFRP’s direction-related elasticity and its anisotropic behavior precisely meets these requirements.”

Design and production decisions

The first challenge the team faced was how best to produce the strut bars to help ensure a very stiff and strong part that also would be cost-effective. To meet mechanical requirements, a high fiber-volume fraction of aligned, continuous carbon fibers would be crucial. Given the temperature specs in this area of the undercarriage (near the exhaust system), a high-performance polymer with excellent ability to bond to carbon fiber was necessary. Epoxies were deemed the best choice for Daimler’s material-release process as well as for meeting processing, temperature and cost targets.

Because there was a good chance that — assuming the technology was successful — it would be expanded to other Mercedes-AMG or Mercedes-Benz vehicles, the team needed a process with low tooling costs that was scalable to keep expenses manageable as production volumes increased. From a design standpoint, still another issue was that the basic geometry of the strut itself was a solid rectangular billet, but mounting hardware (force-transmission points) on each end of the bars needed to be added to facilitate connections and transfer loads.

After an internal review, researchers determined that one process would best meet project goals. “We considered all relevant processes right from the beginning,” recalls Dr. Karl-Heinz Füller, Daimler’s manager – hybrid material and concepts. “However, with our demanding performance requirements and tight cost situation, only pultrusion could provide feasible economics.” Team research, which included a complete lifecycle analysis (LCA) that is done for all new production processes introduced at the company, showed that not only did pultrusion operate with virtually no waste — important with high-value CFRP materials — but that it also was the most cost-competitive composites process because it requires relatively little energy (owing to low process forces) and has negligible tooling costs. These features would be important at the start of the project and later, should the CFRP strut program expand to other, higher-volume vehicles.

“Our strategy at Daimler for using CFRP is to start our applications with more exclusive, lower-volume vehicles, like Mercedes-AMG cars,” adds Füller. “That gives the CFRP supply chain — fiber and resin producers as well as processors — the time they need to further develop the cost position to meet the demands of high-volume productions. We felt the pultrusion process had the best opportunities of all composite technologies to get developed into this direction.”

The team began the hard work of optimizing the pultruded strut’s design with epoxy and carbon fiber, running numerous static and dynamic simulations on complete vehicle models in NX Nastran (from Siemens PLM Software Inc., Munich, Germany), including noise/vibration/harshness (NVH), crash, fatigue and delta-alpha simulations (coefficient of linear thermal expansion (CLTE) differentials) using different ambient temperatures. Significant effort was expended to define the best layup of rovings for different carbon fiber types — from 12-50K — to achieve the part’s high mechanical performance. Although initial commercial designs featured pure CFRP composite, several years of simulation and physical testing of numerous material and design variants taught the team several things and shifted the focus to a hybrid-composite design with the following features:

First, more economical 48-50K carbon fiber tow would work and the CFRP part was likely to be 45-60% lighter than steel benchmarks. Multiplied by two or four struts, depending on the vehicle, the savings would increase.

Second, to address concerns about galvanic corrosion between the carbon fiber and metal connection hardware, as well as surrounding metallic structures, and to prevent damage from stone chips kicked up by tires, the team decided to add a protective top layer of slightly heavier but less costly fiberglass. The glass also improved damping values.

Third, simulations showed that it would be beneficial to add a thin steel core to the pultruded profile to increase its ductile crash behavior and offer new cost-efficient mounting designs. In the end, use of the metallic core — which is formed using high-strength steel (0.8-1.2mm/0.03-0.5 inches in diameter, depending on application) and fed directly into the pultrusion die along with glass and carbon fibers — also made it easier to insert attachment bushings into the struts. All metallic hardware directly touching the struts is protected by either coatings or adhesives or both.

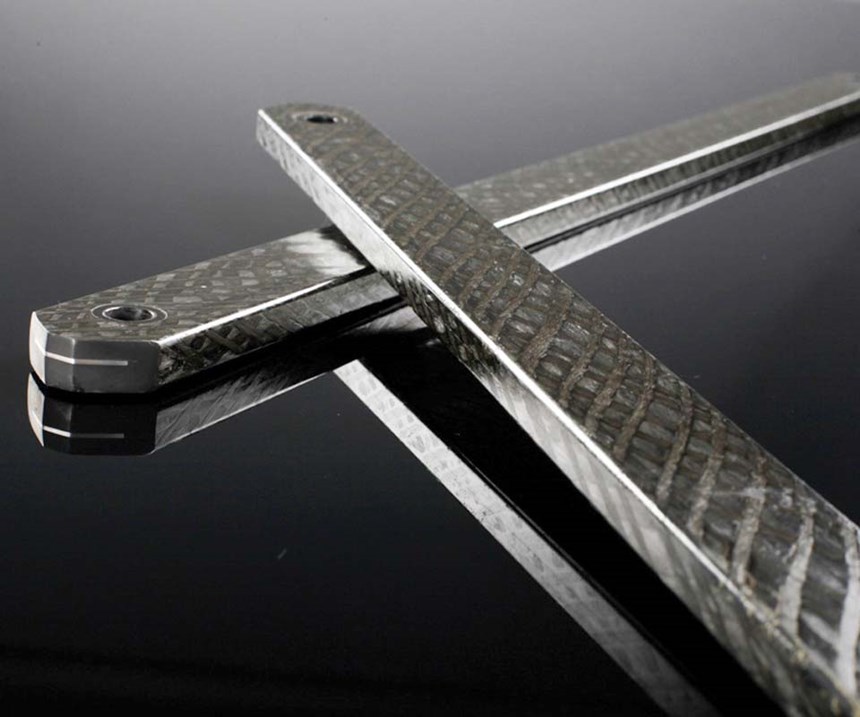

Initially an all-CFRP and, later, a hybrid (steel-cored, carbon and glass fiber-reinforced epoxy) composite, the struts were produced by Secar Technologies GmbH (Mürzzuschlag-Hönigsberg, Austria). The strut body is cut from a pultruded profile. Typical length is 0.8-1.3m (2.6-4.3 ft), typical width is 35 mm/1.4 inches, and typical thickness is 8.0 mm/0.31 inch). Holes are drilled and bushings installed. Using standard surface prep, attachment hardware is bonded to each end of the bar via structural epoxy adhesives. Bonding currently is the rate-limiting step in the production process; pultrusion is quite capable of maintaining a high-volume production rate.

“Thanks to the dedicated mix of various glass and carbon fibers, a high-performance resin and a high-strength metal band at the core, the function and cost of our material mix was optimized,” notes Ralf Bernhardt, Mercedes-AMG’s manager – body-in-white development. “That made it possible for us to optimize other component functions, such as damping and corrosion characteristics, temperature resistance and crash performance. In combination with the impressive economic efficiency of the manufacturing process, this provides the ideal conditions for larger production volumes.”

Award-winning design expands to more vehicles

Initially, pure CFRP strut bars were introduced on Mercedes-Benz SLS AMG Coupé Black Series vehicles in 2013. Since then, further design and process developments were applied cost-effectively to vehicles with much greater volumes, such as the Mercedes-AMG C-Class C63/C63S coupés/cabriolets (2016), AMG GT R (2017), and AMG Mercedes S-Class (2017). The application also won the 2016 Innovation Award from the Verstärkte Kunststoffe e.V. (AVK) industry association at the Composites Europe conference.

Although the CFRP and hybrid struts are more costly than earlier steel struts, they meet Daimler’s ambitious lightweighting requirements and achieve other benefits as well. “Local stiffness improvements in the right areas lead to a more precise, harmonic, trustful driving experience,” notes Bernhardt. “That means that less-experienced drivers can drive more safely and faster, and experienced drivers can drive much faster because it takes less time to understand the character and behavior of the car.” He adds that final handling evaluations are subjective and measurable benefits are vehicle-specific.

“For an automotive development engineer, the effort to develop a CFRP part compared to a metal one is significantly higher,” Füller reminds us. “Finding a partner that is capable to handle a large automotive series with all boundary conditions, including a satisfactory profit margin, has been a quite challenging journey.” Nonetheless, he adds that while the opportunity to convert metal struts to CFRP on passenger cars is limited, still the lessons learned in terms of design and bonding can be applied to other composite structures. A quick look at CFRP innovation on other Mercedes-AMG vehicles shows the team has done just that.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)