IACMI SMC Workshop: From What to Why

Introductory course teaches students about composition, characteristics, benefits of sheet-molding compound.

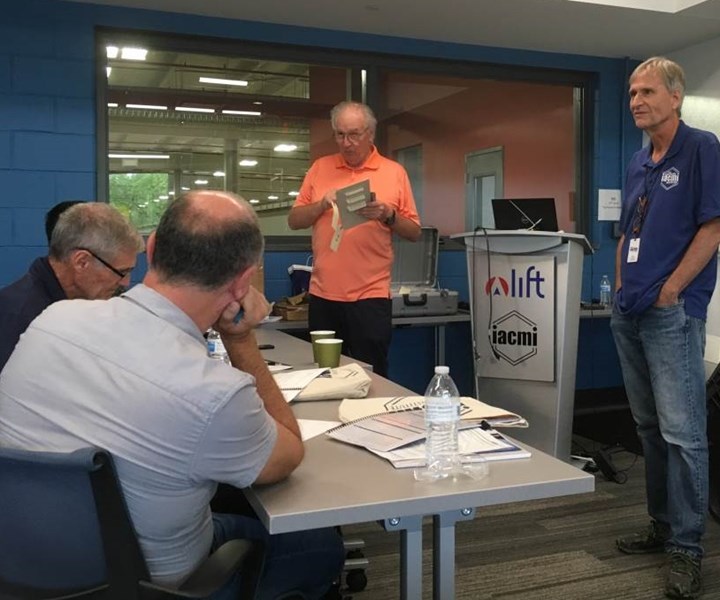

IACMI SURF in Detroit hosted a two-day SMC workshop in late August that was attended by students representing a cross-section of the composites supply chain. In addition to spirited classroom instruction, the course also included observation of an SMC molding trial of a full-size automotive part, plus an exercise where the class identified common molding defects on SMC parts. The workshop was taught by retired industry veterans Jim Plaunt, MSU senior consultant-composites (orange shirt) and Dan Houston, MSU senior materials and process engineer (blue shirt). CW photo | Peggy Malnati

On August 21 and 22, 17 people attended an introductory workshop on sheet molding compound (SMC) at the Detroit-based Scale-Up Research Facility (SURF) managed and operated by Michigan State University (MSU, East Lansing, Mich., U.S.) for the Institute for Advanced Composites Manufacturing Innovation (IACMI, Knoxville, Tenn., U.S.). Taught by retired industry veterans Jim Plaunt, MSU senior consultant-composites, and Dan Houston, MSU senior materials and process engineer — both of whom work part-time at the SURF facility — the two-day workshop was a mix of classroom instruction, observing an SMC molding trial and examining SMC defects on molded parts.

Shane Skop, MSU composites engineering manager (left) and Brian Klotz, MSU composites materials and processing technician (right) prepare their charges of SMC material prior to loading them into the press during the molding trial observed by workshop participants. CW photo | Peggy Malnati

At the start of the class, Plaunt told a story from early in his career that illustrated why he wanted students to not just learn “the what” about SMC but also “the why,” and to ask questions if the latter wasn’t explained. To that end, the first day of the course covered what SMC is, why it’s used, how it compares with other composites and metals, important markets and typical compositions — including what the various resins, fillers, reinforcements, initiators, internal mold release agents, pigments, chemical thickeners, inhibitors, viscosity reducers and monomers contribute. The topic then shifted to looking at first-through-fourth-generation technologies used to control shrinkage, and the opportunities and challenges of adding reinforcements. The day ended with a discussion of the complexity of SMC compounding. On the second day, the compression molding process (along with several process variants) were described. Next, key aspects of tool design, the importance of practicing good manufacturing discipline, layup techniques, curing and demolding, and secondary operations were covered.

The class then moved downstairs to observe an outer/Class A SMC liftgate panel being molded, including the time parts spent in a cooling/check fixture between molding cycles.

Instructors, molding technicians and students from the SMC workshop pose beside the 4,000 metric-ton short-stroke compression press produced by Schuler AG (Göppingen, Germany) at MSU’s SURF facility. CW photo | Peggy Malnati

After a quick tour of the equipment available for members and outside parties to use, the class moved back upstairs, where it was split into small teams that were tested by having to identify SMC defects on molded parts that Plaunt has collected over his many decades in the industry. To help with this exercise, students received a second workbook, this one covering defects (including good descriptions of what defects looks like and what causes them) followed by probable corrective actions in order of importance. That document alone was worth the cost of admission. After “graduation” from the workshop, each attendee was presented with a USB drive containing that SMC troubleshooting guide to share with colleagues.

Interestingly, attendees represented a cross-section of the composites supply chain and had a broad range of composites experience. There were toolmakers, press manufacturers, fiber suppliers, materials suppliers and molders present. There were design engineers with a background in metals wanting to learn about composites; there were tooling and process engineers who had previously worked with composite prepreg and wanted to learn more about SMC; and there was an application development engineer whose company was thinking about adding SMC to the thermoplastic composites it already molded. There also were representatives from tier suppliers looking for molding partners, as well as those considering joining IACMI who wanted to see what the organization offered.

For the final exercise in the IACMI SMC workshop, the class was split into small teams and asked to identify common defects in SMC parts. About half the class is shown holding samples of parts Plaunt had collected over his many decades of experience in the industry. Even veteran industry members remarked that they learned something new in the class. CW photo | Peggy Malnati

Tier 1 Magna Exteriors (Troy, Mich., U.S.) sent three members from its Polygon Industries division in Guelph, Ont., Canada. Tier 1 Valeo Wiper Systems (Saint-Ouen, France) sent six attendees from its Auburn Hills, Mich., U.S., facility. Heavy-duty metals press manufacturer Macrodyne Technologies Inc. (Concord, Ont., Canada) had two representatives in the class. Compression molding toolmaker Snider Mold Co. Inc. sent one attendee. Fiberglass supplier Owens Corning (Toledo, Ohio, U.S.) sent two people to the class. And thermoplastic composite molder and glass-mat thermoplastic supplier Hanwha Advanced Materials America (Warren, Mich., U.S.) sent one student.

Related Content

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreAutomotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MoreThermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)